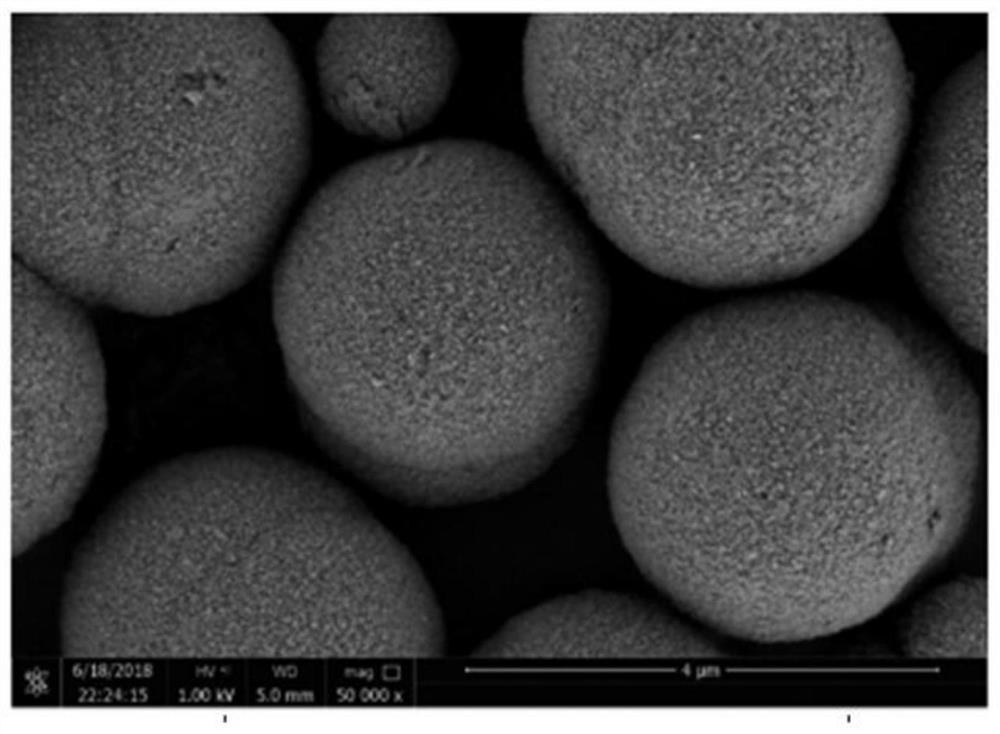

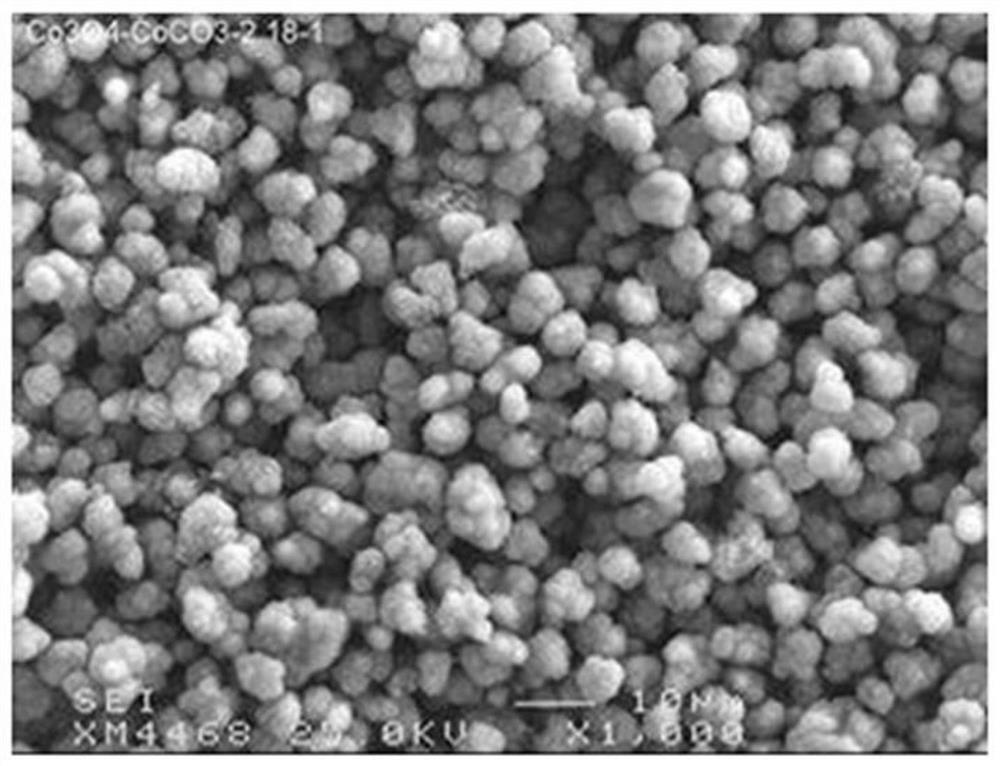

A kind of preparation method of tricobalt tetroxide with small and uniform particle size

A technology of cobalt tetroxide with small particle size, applied in the direction of cobalt oxide/cobalt hydroxide, etc., can solve the problems of large particle size of cobalt tetroxide, difficult to control the preparation process, easy to sinter, etc., to achieve uniform and controllable particle size, good sphericity, and saving effect of time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0029] In this example, small pellets of cobalt tetroxide were prepared through the following steps:

[0030] (1) Preparation solution: Dissolve cobalt sulfate in hot water at 80°C to obtain a cobalt salt solution with a concentration of 1.6mol / L; dissolve ammonium carbonate in hot water at 80°C to obtain a cobalt salt solution with a concentration of 10mol / L Bottom fluid;

[0031] (2) Colloidal reaction: Stir the bottom liquid prepared in step (1) at room temperature at a speed of 30 rpm, add the cobalt salt solution prepared in step (1) to the stirred bottom liquid at a constant speed, and add the cobalt salt solution every minute The volume of the solution is 7% of the volume of the bottom liquid. During the process of adding the cobalt salt solution, the bottom liquid is treated with 20KHz ultrasonic waves. The processing time is 30 minutes after the addition of the cobalt salt solution, so that the reaction forms a great supersaturation and produces a uniform floc colloi...

Embodiment 2

[0037] In this example, small pellets of cobalt tetroxide were prepared through the following steps:

[0038] (1) Preparation solution: Dissolve cobalt chloride in hot water at 60°C to obtain a cobalt salt solution with a concentration of 2mol / L; dissolve ammonium carbonate in hot water at 60°C to obtain a cobalt salt solution with a concentration of 15mol / L Bottom fluid;

[0039] (2) Colloidal reaction: Stir the bottom liquid prepared in step (1) at a speed of 50 rpm at room temperature, add the cobalt salt solution prepared in step (1) into the stirred bottom liquid at a constant speed, and add the cobalt salt solution every minute The volume of the solution is 5% of the volume of the bottom liquid. During the process of adding the cobalt salt solution, the bottom liquid is treated with 25KHz ultrasonic waves. The processing time is 30 minutes after the addition of the cobalt salt solution, so that the reaction forms a great supersaturation and produces a uniform floc collo...

Embodiment 3

[0045] In this example, small pellets of cobalt tetroxide were prepared through the following steps:

[0046] (1) Preparation solution: Dissolve cobalt nitrate in hot water at 60°C to obtain a cobalt salt solution with a concentration of 1.5mol / L; dissolve ammonium bicarbonate in hot water at 60°C to obtain a concentration of 11mol / L bottom liquid;

[0047] (2) Colloidal reaction: Stir the bottom liquid prepared in step (1) at room temperature at a speed of 40 rpm, add the cobalt salt solution prepared in step (1) to the stirred bottom liquid at a constant speed, and add the cobalt salt solution every minute The volume is 3% of the volume of the bottom liquid. During the process of adding the cobalt salt solution, the bottom liquid is treated with 40KHz ultrasonic waves. The processing time is 30 minutes after the addition of the cobalt salt solution, so that the reaction forms a great supersaturation and produces a uniform floc colloid. When the molar ratio of cobalt nitrat...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com