Microchannel continuous sulfonation synthesis method of ultraviolet light absorber BP-4

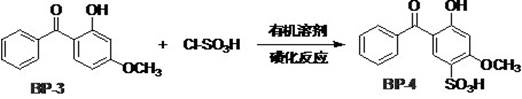

The technology of BP-4 and absorbent, which is applied in the field of preparation of ultraviolet absorbent BP-4, can solve the problems of corrosiveness of reaction equipment, cumbersome post-processing and high production cost, and achieves low industrial cost, low raw material cost and easy operation. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0032] The microchannel continuous sulfonation synthesis of the ultraviolet absorber BP-4 of the present embodiment, including the steps of: 22.8 g of 2-hydroxy-4-methoxy-diphenone ketone (dissolved in 90 ml of dichloroethane) Configure a clear raw material solution, 2-hydroxy-4-methoxy-benzophenone raw material solution and trioxide, respectively, from 25 ml / min, 0.64 l / min, respectively, and flow into the microchannel reactor. The reaction temperature is 100 ° C, the pressure is 1.0 MPa, the residence time is 2.0 min, the reaction liquid flowing out of the reactor is collected, and the ultraviolet absorbent BP-4 product solution, the organic solvent is recovering, and the crystal is cooled to obtain a light yellow ultraviolet absorption. The agent BP-4 was 32 g, and the purity of the BP-4 crude material was 96.13%.

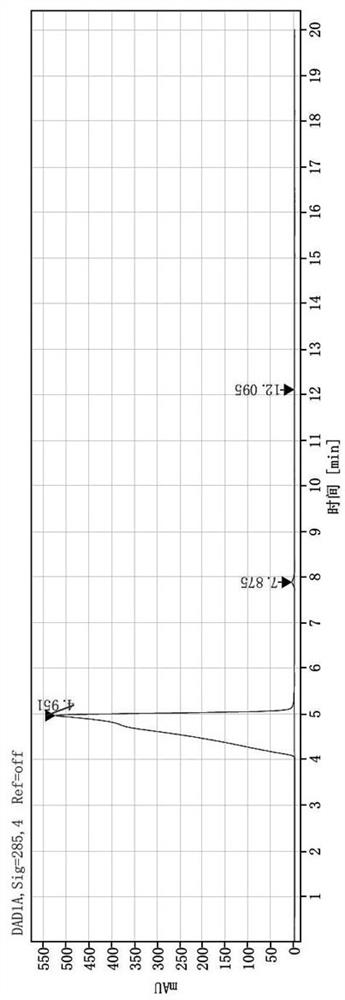

[0033] The above product was crystallized from 160 ml of ethanol, filtered, dried. 99.57% (see attached figure 1 : High performance liquid chromatograph: Agilen...

Embodiment 2

[0040] The microchannel continuous sulfonation synthesis of the ultraviolet absorber BP-4 of the present embodiment includes the steps of: 2-hydroxy-4-methoxy-dibenzophenone 228 g is soluble in 900 ml of trichloroethane configuration Curable raw material solution, 2-hydroxy-4-methoxy-dibenzophenone raw material solution and trioxide, respectively, from 30 ml / min, 0.77 l / min, respectively, feed into the microchannel reactor, reaction The temperature is 90 ° C, the pressure is 1.5 MPa, the residence time is 3.3 min, collecting the reaction liquid flowing out of the reactor to obtain an ultraviolet absorber BP-4 product solution, and the organic solvent is recovered, and the crystal is cooled to obtain a light yellow ultraviolet absorber BP. -4 crude 310g, the BP-4 crude purity was 96.26%.

[0041] The above product was crystallized from 1.7L ethanol, filtered, dried. It is 99.43%.

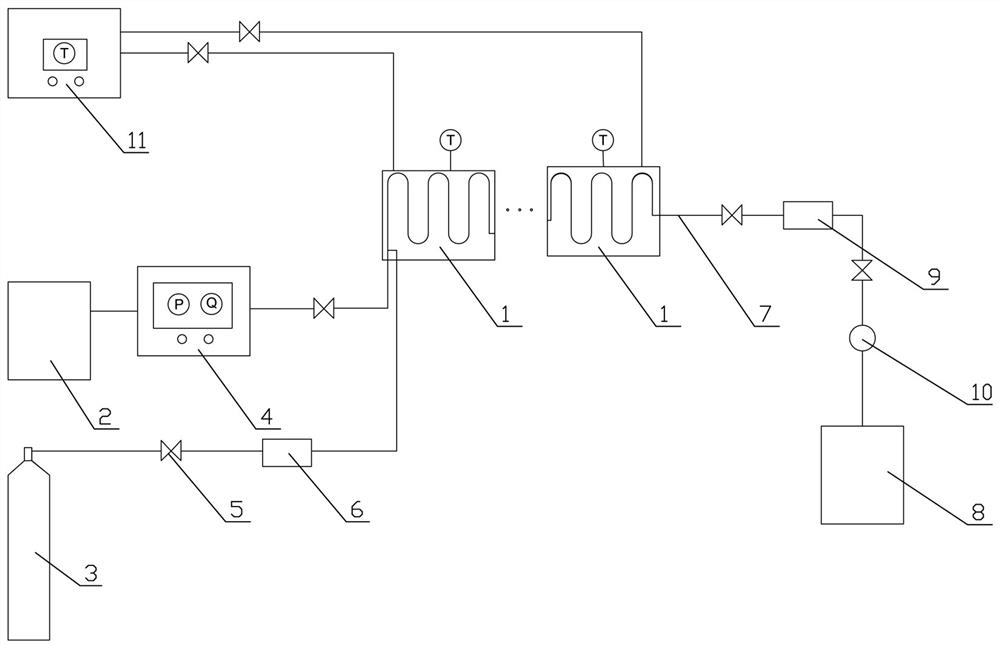

[0042] In this example, the apparatus for preparing a microchannels of UV absorbent BP-4 is used ...

Embodiment 3

[0044] The microchannel continuous sulfonation synthesis of the ultraviolet absorber BP-4 of the present embodiment includes the steps of: weighing 2-hydroxy-4-methoxy-dibenzophenone 114 g is formed into 450 ml of trichlorethylene. The clear raw material solution, 2-hydroxy-4-methoxy-diphenone ketone raw material solution and sulfur dioxide are respectively 20 ml / min, 0.51L / min, respectively, and flow into the microchannel reactor, reaction temperature. It is 50 ° C, the pressure is 0.5 MPa, the residence time is 4.5min, the reaction mixture flowing out of the reactor is collected, and the ultraviolet absorber BP-4 product solution is obtained, and the organic solvent is recovered at normal pressure, cooling crystals, to obtain a pale yellow ultraviolet absorber BP- 4 crude 155 g, the BP-4 crude purity was 95.36%.

[0045] The above product was crystallized from 1.2 l ethanol, filtered, dried. 99.29%

[0046] In this example, the apparatus for preparing the microfield continuo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com