Fe-based multifunctional catalyst as well as preparation method and application thereof

A catalyst and functional technology, applied in the field of Fe-based multifunctional catalyst and its preparation, can solve the problems of unclear catalytic network, insufficient research on reaction mechanism, low ethanol yield, etc., and achieve simple preparation process, high economic value and Social benefits and low cost effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

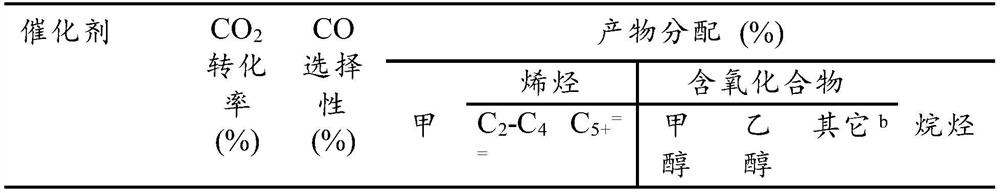

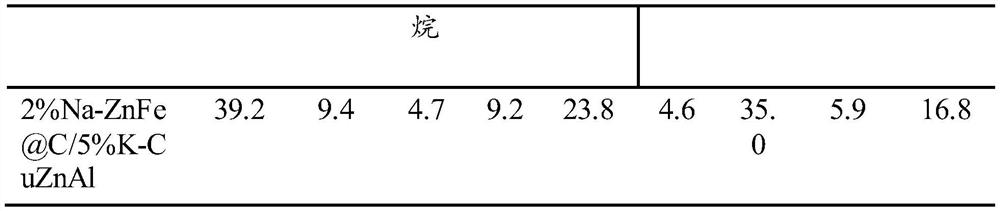

Examples

Embodiment 1

[0077] S1, by carbonizing Fe-based metal-organic frameworks (ZnFe-MOFs), and then using Na 2 CO 3 Perform alkali metal impregnation and drying to prepare 2% Na-ZnFe@C catalyst. The specific experimental process is as follows:

[0078] 1mmol Zn(NO 3 ) 2 .6H 2 O (0.297g) and 0.6g FeCl 2 .4H 2 Dissolve O (3mmol) in 50ml DMF, add 0.22g triethylenediamine and stir for 30 minutes to form solution A; dissolve terephthalic acid (4.2mmol, 0.70g) in 10mL DMF to form solution B; add solution B to A After the solution was stirred for 1 h, it was transferred to a hydrothermal kettle and heated at 120 °C for 24 h; after the product was centrifuged, it was washed 3 times with DMF, and then dried in a vacuum oven at 60 °C overnight to obtain ZnFe-MOFs.

[0079] The obtained ZnFe-MOFs were carbonized in a tube furnace under a nitrogen atmosphere, and the carbonization temperature was controlled at 550 °C for 3 h. After natural cooling to room temperature, the ZnFe@C catalyst was obtain...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com