Method for brazing SiCf/SiC ceramic-based composite material and nickel-based superalloy

A technology of nickel-based superalloys and composite materials, applied in welding equipment, metal processing equipment, manufacturing tools, etc., can solve the problem of large differences in thermal expansion coefficient and elastic modulus, difficult connection of ceramic matrix composite materials, and mismatching degree of deformation The problem of increasing the degree of increase, to achieve the effect of promoting diffusion, good application prospects, and reducing generation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

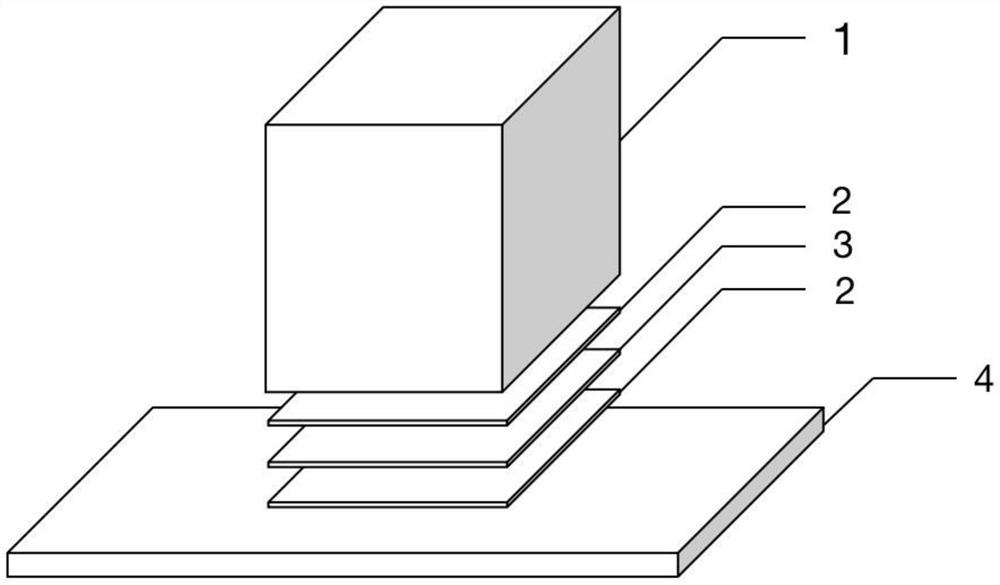

Image

Examples

Embodiment 1

[0060] Embodiment 1 of the present invention discloses a SiC f The method for brazing / SiC ceramic matrix composite material and nickel base superalloy specifically comprises the following steps:

[0061] (1) Polish the nickel-based superalloy and solder foil with 200-mesh, 400-mesh, 600-mesh and 800-mesh sandpaper in sequence, and then add acetone to ultrasonic pretreatment for 10min-20min to remove surface impurities to obtain pretreated nickel-based high-temperature Alloy and pretreated solder foil; wherein, the ultrasonic pretreatment frequency is 40KHz;

[0062] The nickel-based superalloy is GH536 alloy, with a size of 5mm×7mm×2mm;

[0063] The solder foil is AgCuTi solder foil with a thickness of 50 μm and a size of 5mm×4mm;

[0064] (2) Grinding the ceramic matrix composite material with 800-mesh sandpaper, adding it to acetone, ultrasonic pretreatment for 10 minutes, and removing surface impurities to obtain a pretreated ceramic matrix composite material; wherein, th...

Embodiment 2

[0072] Embodiment 2 of the present invention discloses a C f The method for brazing of / C ceramic matrix composite material and nickel-base superalloy specifically comprises the following steps:

[0073] (1) Polish the nickel-based superalloy and solder foil with 200-mesh, 400-mesh, 600-mesh and 800-mesh sandpaper in sequence, and then add acetone for ultrasonic pretreatment for 10 minutes to remove surface impurities to obtain pretreated nickel-based superalloy and Pretreating the solder foil; wherein, the ultrasonic pretreatment frequency is 40KHz;

[0074] The nickel-based superalloy is GH536 alloy, with a size of 5mm×7mm×2mm;

[0075] The solder foil is AgCuTi solder foil with a thickness of 50 μm and a size of 5mm×4mm;

[0076] (2) Grinding the ceramic matrix composite material with 800-mesh sandpaper, adding it to acetone, ultrasonic pretreatment for 10 minutes, and removing surface impurities to obtain a pretreated ceramic matrix composite material; wherein, the ultra...

Embodiment 3

[0084] Embodiment 3 of the present invention discloses a SiC f The method for brazing / SiC ceramic matrix composite material and nickel base superalloy specifically comprises the following steps:

[0085] (1) Polish the nickel-based superalloy and solder foil with 200-mesh, 400-mesh, 600-mesh and 800-mesh sandpaper in sequence, and then add acetone to ultrasonic pretreatment for 10min-20min to remove surface impurities to obtain pretreated nickel-based high-temperature Alloy and pretreated solder foil; wherein, the ultrasonic pretreatment frequency is 40KHz;

[0086] The nickel-based superalloy is GH536 alloy, with a size of 5mm×7mm×2mm;

[0087] The solder foil is AgCuTi solder foil with a thickness of 50 μm and a size of 5mm×4mm;

[0088] (2) Grinding the ceramic matrix composite material with 800-mesh sandpaper, adding it to acetone, ultrasonic pretreatment for 10 minutes, and removing surface impurities to obtain a pretreated ceramic matrix composite material; wherein, th...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com