In-situ ultrasonic flame-retardant protection method for wood structure ancient building in northwest region

A technique of ancient buildings, wooden structures

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

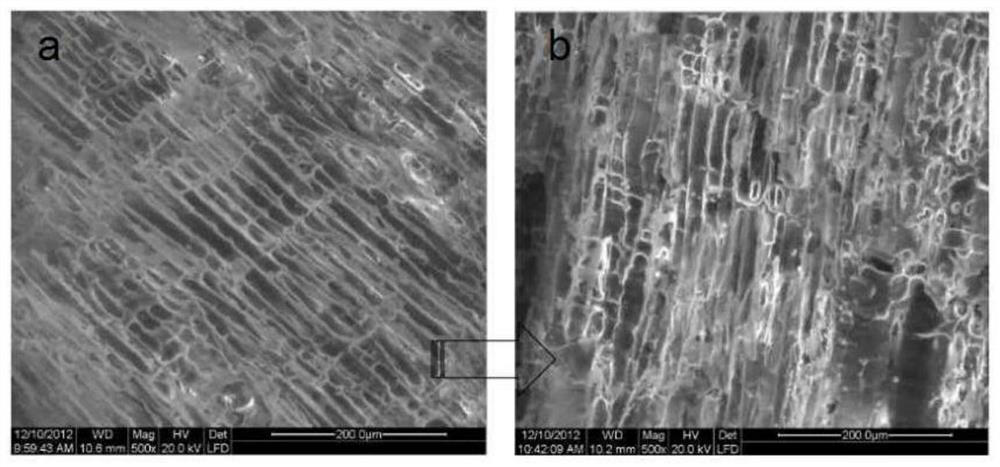

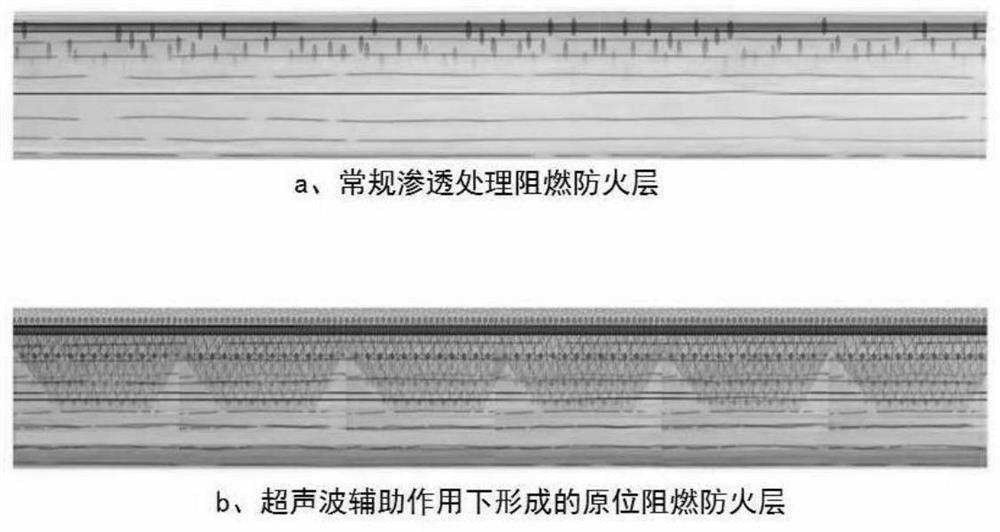

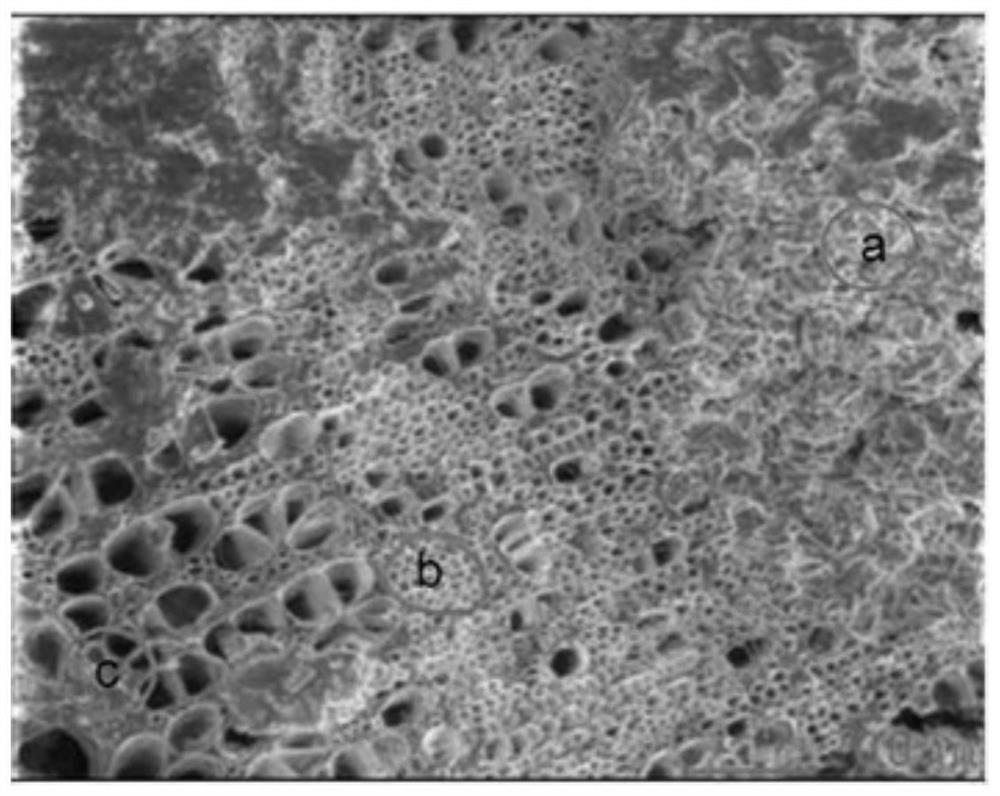

Image

Examples

Embodiment 1

[0031] An in-situ ultrasonic flame-retardant protection method for ancient wooden structures in Northwest China, comprising the following steps:

[0032] Step 1: Clean the surface of the wooden structure building, use a dry soft brush to clean the surface of the wooden components of the ancient building, and thoroughly remove the floating dust and dirt that stick to the surface of the wooden components.

[0033] The second step: dissolving 0.01mol / L zinc acetate solution to prepare No. 1 humidity control material for use.

[0034] Step 3: prepare a 0.05 mol / L phytic acid aqueous solution to prepare No. 2 flame retardant material for use.

[0035] Step 4: Ultrasonic disperse octadecyltrimethoxysilane in ethanol aqueous solution to prepare No. 3 reinforcement material for use. The volume ratio of deionized water and ethanol is 9:1. In the aqueous solution of octadecyltrimethoxysilane ethanol, the mass percentage of the solute is 3%.

[0036] Step 5: In-situ flame retardant rei...

Embodiment 2

[0041] An in-situ ultrasonic flame-retardant protection method for ancient wooden structures in Northwest China, comprising the following steps:

[0042]Step 1: Clean the surface of the wooden structure building, use a dry soft brush to clean the surface of the wooden components of the ancient building, and thoroughly remove the floating dust and dirt that stick to the surface of the wooden components.

[0043] The second step: dissolving 0.02mol / L zinc acetate solution to prepare No. 1 humidity control material for use.

[0044] Step 3: prepare 0.10 mol / L phytic acid aqueous solution to prepare No. 2 flame retardant material for use.

[0045] Step 4: Ultrasonic disperse octadecyltrimethoxysilane in ethanol aqueous solution to prepare No. 3 reinforcement material for use. The volume ratio of deionized water and ethanol is 7:1. In the aqueous solution of octadecyltrimethoxysilane ethanol, the mass percentage of the solute is 5%.

[0046] Step 5: In-situ flame retardant reinfo...

Embodiment 3

[0051] An in-situ ultrasonic flame-retardant protection method for ancient wooden structures in Northwest China, comprising the following steps:

[0052] Step 1: Clean the surface of the wooden structure building, use a dry soft brush to clean the surface of the wooden components of the ancient building, and thoroughly remove the floating dust and dirt that stick to the surface of the wooden components.

[0053] The second step: dissolving 0.03mol / L zinc acetate solution to prepare No. 1 humidity control material for use.

[0054] Step 3: prepare a 0.15 mol / L phytic acid aqueous solution to prepare No. 2 flame retardant material for use.

[0055] Step 4: Ultrasonic disperse octadecyltrimethoxysilane in ethanol aqueous solution to prepare No. 3 reinforcement material for use. The volume ratio of deionized water and ethanol is 3:1. In the aqueous solution of octadecyltrimethoxysilane ethanol, the mass percentage of the solute is 4%.

[0056] Step 5: In-situ flame retardant rei...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com