Halogen-free flame-retardant polyolefin cable material for automobile and preparation method thereof

A polyolefin cable material and automobile technology, applied in the field of material chemistry, can solve the problems that the aging resistance cannot meet the needs of electric wires, there are no industrialized products, and the heat aging resistance of cable materials needs to be further improved, so as to improve the long-term heat aging resistance And light resistance, good extrusion processing fluidity, excellent mechanical properties and electrical properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

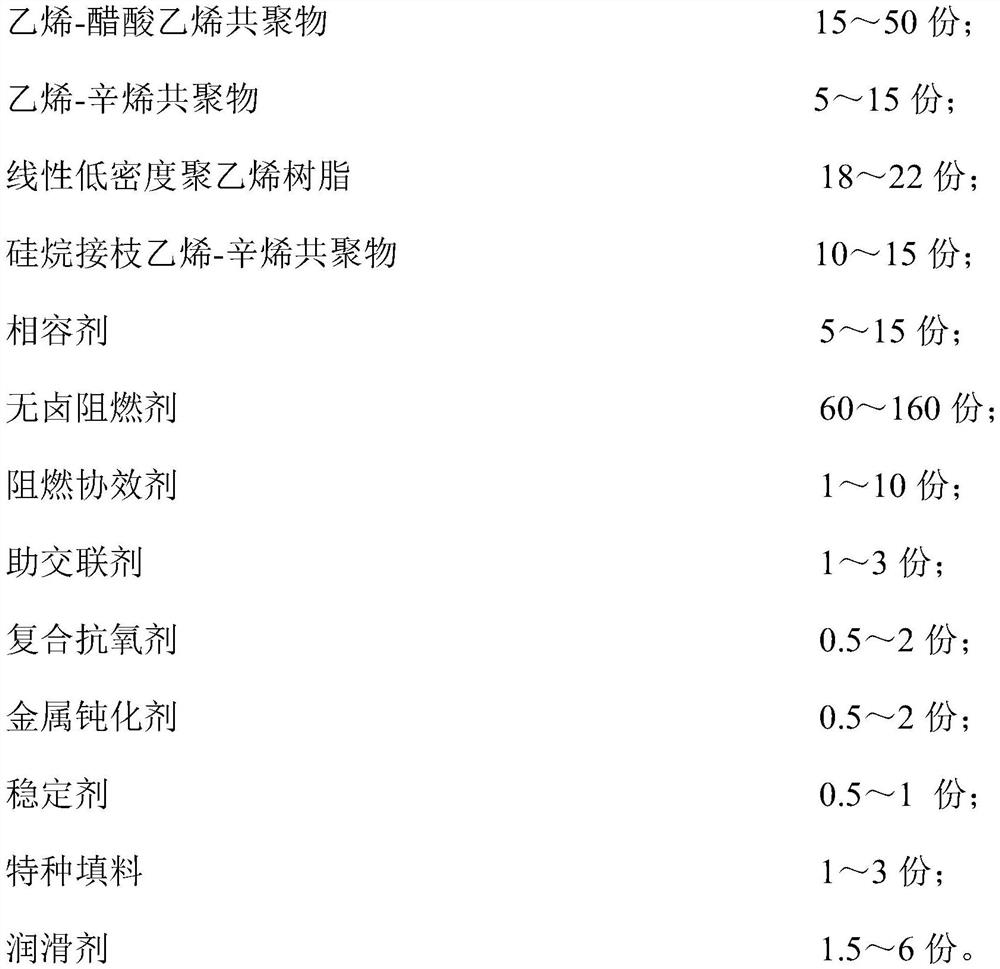

[0067] In this embodiment, a halogen-free flame-retardant polyolefin cable material for automobiles is provided. The raw materials for the preparation of the halogen-free flame-retardant polyolefin cable material for automobiles include the following components in parts by weight:

[0068]

[0069] Among them, the ethylene-vinyl acetate copolymer is an ethylene-vinyl acetate copolymer with a vinyl acetate monomer content of 28wt%, the brand name is Evatane 28-03, and the melt flow rate is 3.0g / (2.16kg, 10min), the manufacturer It is Atofina Company of France; the melt flow rate of ethylene-octene copolymer is 3.5g / (2.16kg, 10min), the brand is DF840, and the manufacturer is Mitsubishi Elastomer Singapore Co., Ltd.; linear low density polyethylene resin The melt flow rate is 2.0g / (2.16kg, 10min), the grade is DFDA7042, and the manufacturer is Sinopec Qilu Branch; the silane-grafted ethylene-octene copolymer is vinyltriethoxysilane-grafted ethylene- Octene copolymer, wherein ...

Embodiment 2

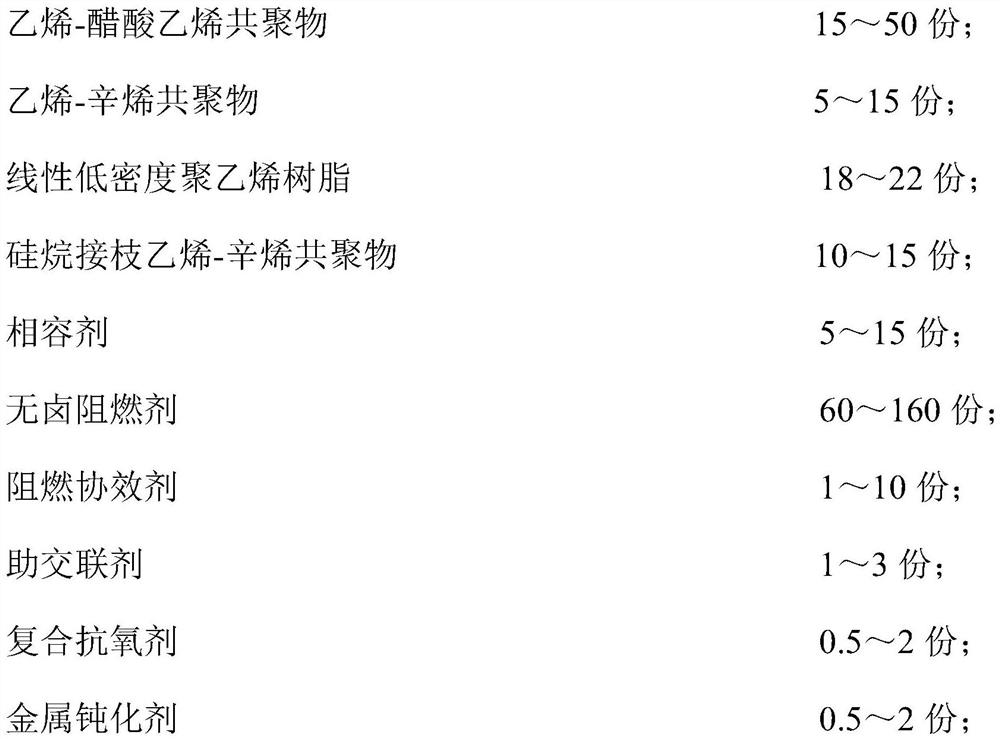

[0076] In this embodiment, a halogen-free flame-retardant polyolefin cable material for automobiles is provided. The raw materials for the preparation of the halogen-free flame-retardant polyolefin cable material for automobiles include the following components in parts by weight:

[0077]

[0078]Among them, the ethylene-vinyl acetate copolymer is an ethylene-vinyl acetate copolymer with a vinyl acetate monomer content of 28wt%, the brand name is Evatane 28-03, and the melt flow rate is 3.0g / (2.16kg, 10min), the manufacturer It is Atofina Company of France; the melt flow rate of ethylene-octene copolymer is 3.5g / (2.16kg, 10min), the brand is DF840, and the manufacturer is Mitsubishi Elastomer Singapore Co., Ltd.; linear low density polyethylene resin The melt flow rate is 2.0g / (2.16kg, 10min), the grade is DFDA7042, and the manufacturer is Sinopec Qilu Branch; the silane-grafted ethylene-octene copolymer is vinyltriethoxysilane-grafted ethylene- Octene copolymer, wherein t...

Embodiment 3

[0081] In this embodiment, a halogen-free flame-retardant polyolefin cable material for automobiles is provided. The raw materials for the preparation of the halogen-free flame-retardant polyolefin cable material for automobiles include the following components in parts by weight:

[0082]

[0083]

[0084] Among them, the ethylene-vinyl acetate copolymer is an ethylene-vinyl acetate copolymer with a vinyl acetate monomer content of 28wt%, the brand name is Evatane 28-03, and the melt flow rate is 3.0g / (2.16kg, 10min), the manufacturer It is Atofina Company of France; the melt flow rate of ethylene-octene copolymer is 3.5g / (2.16kg, 10min), the brand is DF840, and the manufacturer is Mitsubishi Elastomer Singapore Co., Ltd.; linear low density polyethylene resin The melt flow rate is 2.0g / (2.16kg, 10min), the grade is DFDA7042, and the manufacturer is Sinopec Qilu Branch; the silane grafted ethylene-octene copolymer is vinyltrimethoxysilane grafted ethylene-octene ethylen...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com