Low-viscosity I-type porous liquid as well as preparation method and use method thereof

A low-viscosity, liquid technology, applied in separation methods, chemical instruments and methods, gas treatment, etc., can solve the problems of high viscosity and limit large-scale practical applications, and achieve low viscosity, good solution operability advantages, and good long-term The effect of stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

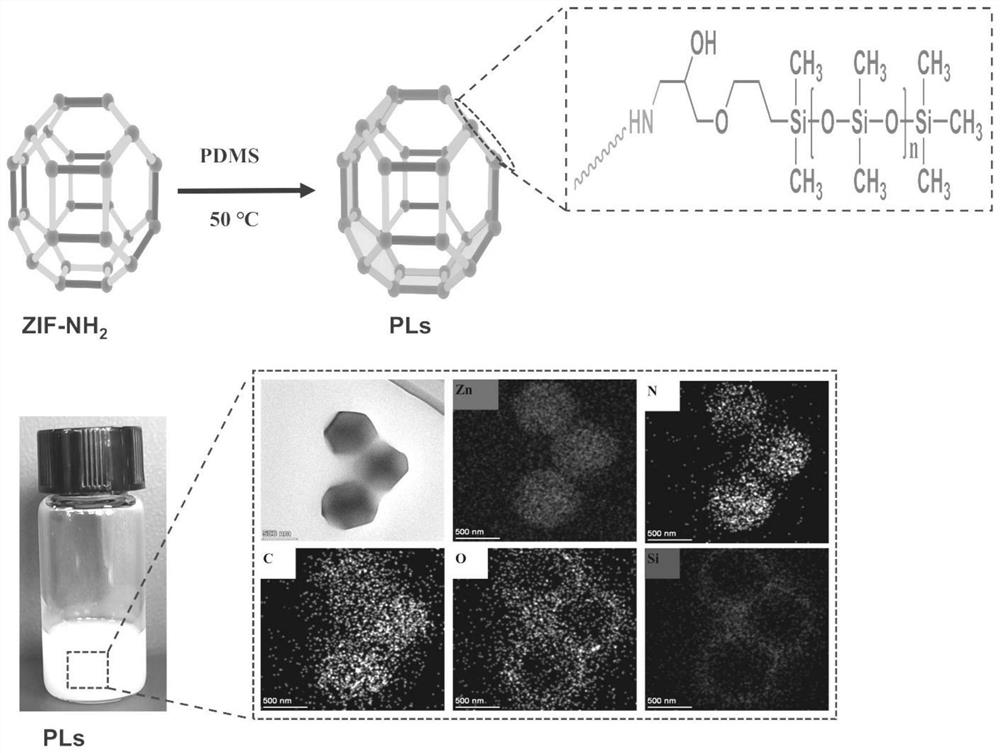

[0037] The preparation of the amino-functionalized porous body is mainly by coating or grafting the amino polymer on the surface of the porous body by impregnation method or in-situ covalent grafting or post-synthesis modification strategy. The preferred amino polymer is branched polyethyleneimine (BPEI) with a molecular weight of 400 to 4000 g·mol -1 .

[0038] The synthesis steps are as follows:

[0039]Step 1: Weigh a certain amount of amino-functionalized porous bodies such as one or more of inherently porous MOFs, ZIFs, COFs or POCs and dissolve them in acetone solvent to form component A;

[0040] Step 2: Weigh a certain amount of single-terminated epoxy PDMS and dissolve it in acetone solvent to form component B;

[0041] Step 3: Mix component A and component B at 30-70°C, stir magnetically for 12-24 hours, and centrifuge to obtain component C of the mixture;

[0042] Step 4: Put component C in a dialysis bag in acetone for dialysis for 48-72 hours, replace the aceto...

Embodiment 1

[0046] (1) Weigh ZIF-8 (0.2g) solid and dissolve it in methanol (20mL), and ultrasonicate for 5 minutes to form solution A; Weigh branched polyethylene BPEI (M n ~600g·mol -1 ) (0.2g) were dissolved in methanol (20mL), and ultrasonicated for 5 minutes to form solution B; at 25°C, solution A and solution B were mixed, magnetically stirred for 24 hours, centrifuged at 6000rpm for 6 minutes, and washed with methanol three times, Dry at 70°C to obtain ZIF-8@BPEI white powder for future use. The ZIF-8@BPEI has an average pore size of 0.72nm and a specific surface area of 1071m 2 g -1 .

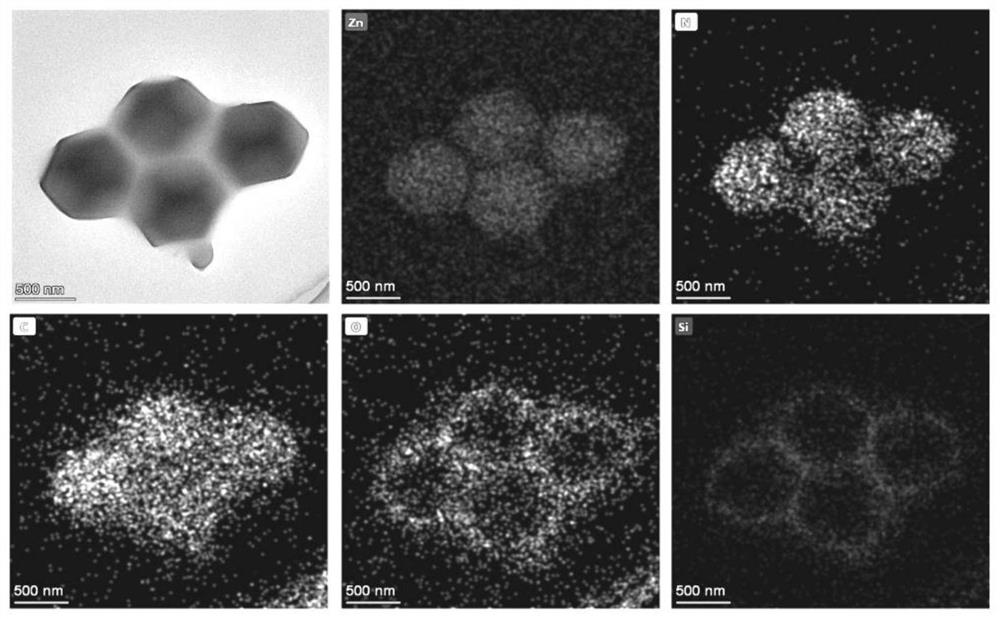

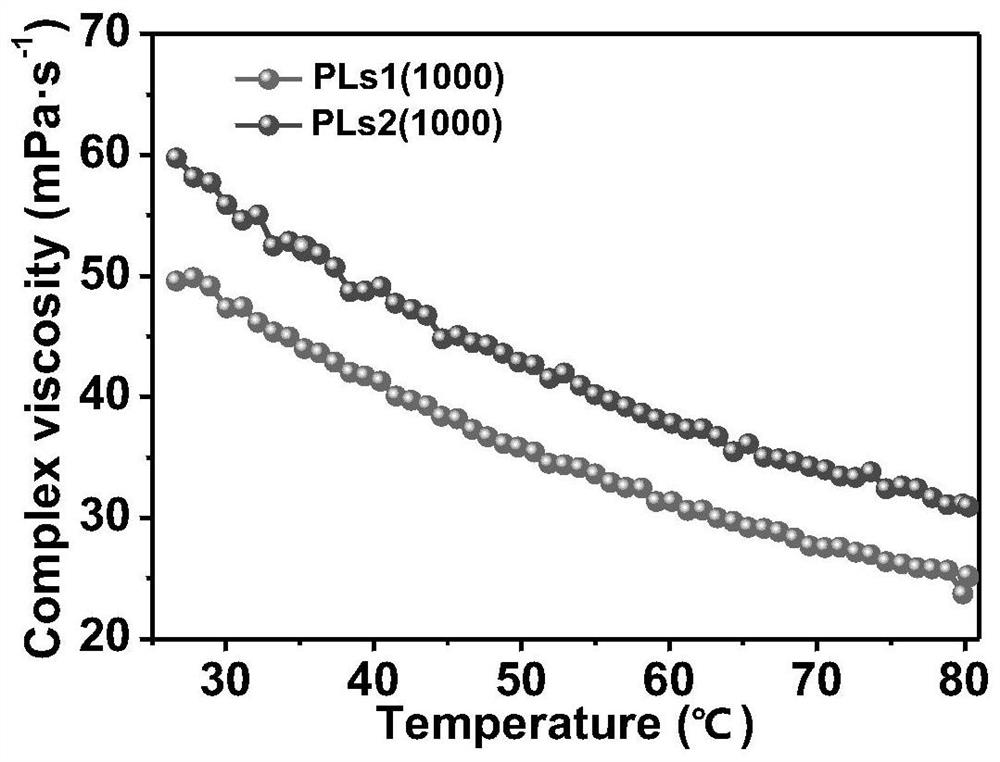

[0047] (2) Weigh ZIF-8@BPEI (0.2g) and dissolve it in acetone (40mL), sonicate for 5 minutes to form solution C; Weigh single-terminal epoxy PDMS (M n ~1000g·mol -1 ) (4g) was dissolved in an acetone solvent, ultrasonicated for 5 minutes to form solution D; solution D was added to solution C at 55°C, magnetically stirred for 12 hours, centrifuged at 8000rpm for 8 minutes, and washed 3 times ...

Embodiment 2

[0051] (1) Weigh Zn(NO 3 ) 2 ·6H 2 O (2g), 2-methylimidazole (12g) and hyperbranched polyolefin BPEI (M n ~600g·mol -1 ) (0.6g) were dissolved in 30mL of methanol to form solutions A, B, and C; at 25°C, the mixture of solutions A, B, and C was magnetically stirred for 24 hours, centrifuged, washed with methanol three times, and dried at 70°C. Obtained ZIF-8-g-BPEI white powder. The ZIF-8-g-BPEI has an average pore diameter of 0.89nm and a specific surface area of 1980m 2 g -1 .

[0052] (2) Weigh ZIF-8-g-BPEI (0.2g) and dissolve it in acetone (40mL), and ultrasonically form solution D for 5 minutes; Weigh single-terminal epoxy PDMS (M n ~1000g·mol -1 ) (4g) was dissolved in acetone solvent, ultrasonicated for 5 minutes to form solution E; solution E was added to solution D at 55°C, magnetically stirred for 12 hours, centrifuged at 8000rpm for 8 minutes, and washed 3 times with acetone to obtain a crude product.

[0053] (3) Dialyze the crude product in acetone solve...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com