Electrolyzed water catalyst applicable to full pH range and preparation method thereof

A technology for electrolyzing water and catalysts, applied in the direction of electrolysis process, electrolysis components, electrodes, etc., can solve the problems of few applications and no research, and achieve the effect of reducing corrosion and cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

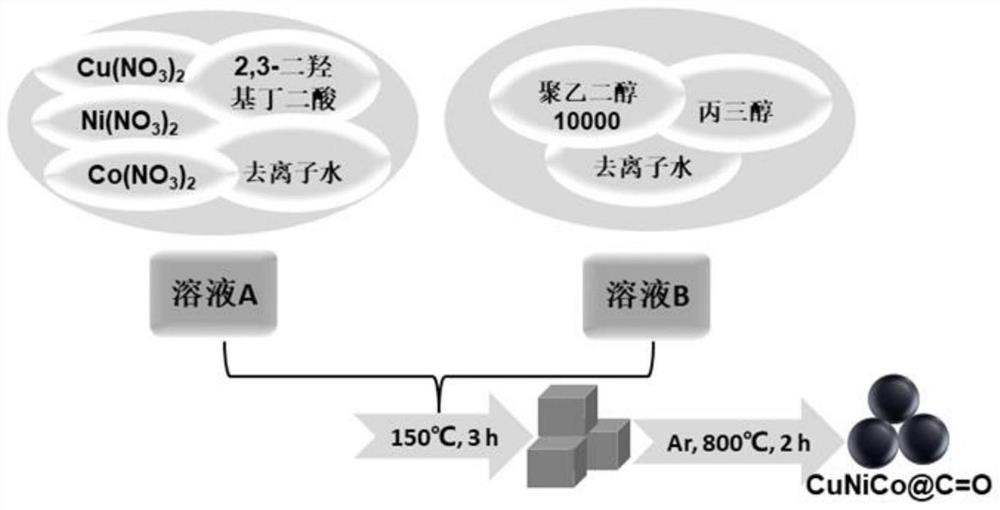

[0041] A method for preparing a carbon-oxygen functional group-modified CuNiCo@C=O catalyst suitable for electrolysis of water in the full pH range, the specific steps are as follows:

[0042] 1. Add 0.003molCu(NO 3 ) 2 ·3H 2 O, 0.003molNi(NO 3 ) 2 ·6H 2 O and 0.005molCo(NO 3 ) 2 ·6H 2 O was dissolved in a certain amount of deionized water, and 0.0120mol of 2,3-dihydroxysuccinic acid was added at the same time, and stirred vigorously to obtain a mixed solution 1;

[0043] 2. Mix 12ml of deionized water and 36ml of glycerol evenly according to the volume ratio, dissolve 4g of polyethylene glycol 10000 in it, stir repeatedly and sonicate to completely dissolve the polyethylene glycol, and obtain the mixed solution 2;

[0044] 3. Under the condition of continuous stirring, add the mixed solution 1 dropwise to the mixed solution 2, and stir for 4 hours to obtain a uniform and clear mixed solution;

[0045] 4. Transfer the mixed solution in step 3 to a 100ml polytetrafluor...

Embodiment 2

[0049] A method for preparing a carbon-oxygen functional group-modified CuNiCo@C=O catalyst suitable for electrolysis of water in the full pH range, the specific steps are as follows:

[0050] 1. Add 0.003molCu(NO 3 ) 2 ·3H 2 O, 0.003molNi(NO 3 ) 2 ·6H 2 O and 0.004molCo(NO 3 ) 2 ·6H 2 O was dissolved in a certain amount of deionized water, and 0.0125mol of 2,3-dihydroxysuccinic acid was added at the same time, and stirred vigorously to obtain a mixed solution 1;

[0051] 2. Mix 12ml of deionized water and 48ml of glycerol evenly, dissolve 5g of polyethylene glycol 10000 in it, stir repeatedly and sonicate to completely dissolve the polyethylene glycol, and obtain the mixed solution 2;

[0052] 3. Under the condition of continuous stirring, add the mixed solution 1 dropwise to the mixed solution 2, and stir for 5 hours to obtain a uniform and clear mixed solution;

[0053] 4. Transfer the mixed solution in step 3 to a 100ml polytetrafluoroethylene reactor, raise the t...

Embodiment 3

[0057] A method for preparing a carbon-oxygen functional group-modified CuNiCo@C=O catalyst suitable for electrolysis of water in the full pH range, the specific steps are as follows:

[0058] 1. Add 0.003molCu(NO 3 ) 2 ·3H 2 O, 0.005molNi(NO 3 ) 2 ·6H 2 O and 0.003molCo(NO 3 ) 2 ·6H 2 O was dissolved in a certain amount of deionized water, and 0.0130 mol of 2,3-dihydroxysuccinic acid was added at the same time, and stirred vigorously to obtain a mixed solution 1;

[0059] 2. Mix 12ml of deionized water and 60ml of glycerol evenly, dissolve 6g of polyethylene glycol 10000 in it, stir repeatedly and sonicate to completely dissolve the polyethylene glycol, and obtain the mixed solution 2;

[0060] 3. Under the condition of continuous stirring, add the mixed solution 1 dropwise to the mixed solution 2, and stir for 6 hours to obtain a uniform and clear mixed solution;

[0061] 4. Transfer the mixed solution in step 3 to a 100ml polytetrafluoroethylene reactor, raise the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com