Preparation method of amorphous silicon heterojunction solar cell with monocrystalline silicon-like substrate

A solar cell and amorphous silicon technology, applied in the field of solar cells, can solve the problems of low conversion efficiency, low open circuit voltage of solar cells, and uncompetitive products, so as to improve minority carrier life, reduce lattice defects, and reduce defect density. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

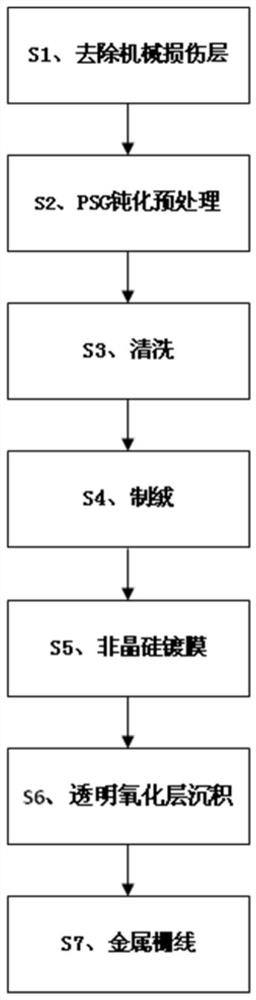

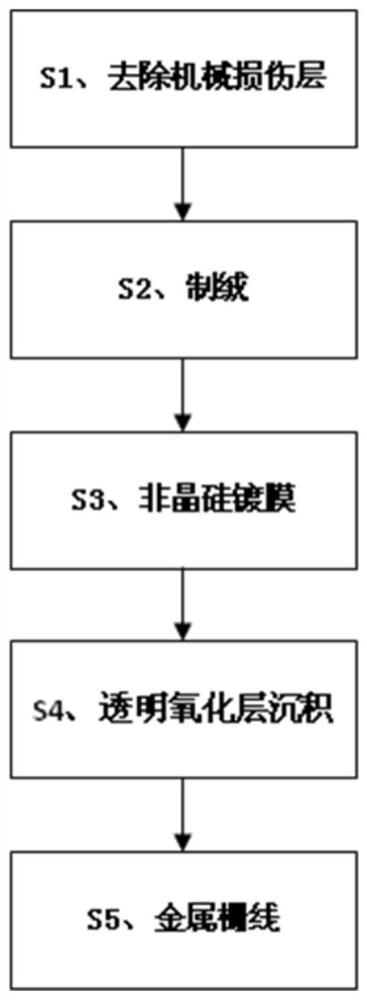

[0031] refer to figure 1 , a method for preparing an amorphous silicon heterojunction solar cell using monocrystalline silicon as a substrate, the method comprising the steps of:

[0032] S1, similar monocrystalline silicon wafers are subjected to mechanical damage layer treatment to remove oil stains and metal particle impurities on the surface; the chemical solution is an alkaline solution, which is one of KOH or NaOH, and the mass percentage of the alkaline solution is 3%-10 %, the mass percentage of deionization is 90%-97%, the treatment time of silicon wafers in alkaline solution is 1-5 minutes, the treatment temperature is 70°C-90°C, and the etching depth of silicon wafers is 5-20um;

[0033] S2. Deposit a layer of PSG on the surface of the silicon wafer and perform heat annealing treatment; perform PSG treatment by high-temperature annealing after phosphorus oxychloride diffusion. The depth range is 0.001um-10um, and a gradual cooling process is adopted;

[0034] S3, ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com