Method for formulating graphite electrode formula by applying energy accumulation height

A technology of graphite electrodes and formulations, which is applied in electric heating devices, electrical components, heating through discharge, etc., can solve the problems of electrodes cracking, falling off and breaking, and achieve the effects of enhancing reliability, adding a reasonable amount, and avoiding electrode cracking

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

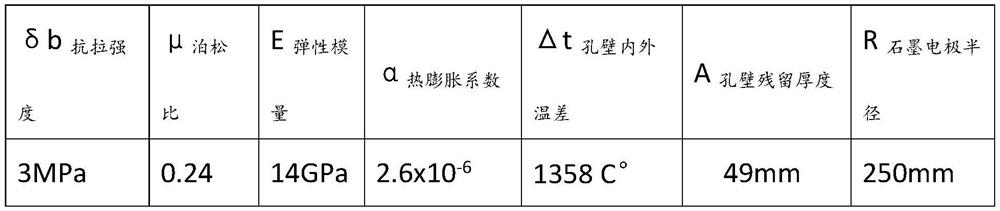

[0112] A steel factory received a large number of low-carbon steel orders, and the smelting steel was changed from the production of medium-carbon steel to the production of low-carbon steel. During production, the refining furnace of the plant frequently experienced carburization of molten steel, causing 7 furnaces of molten steel out of 270 furnaces to be scrapped. The maximum rate of carbon increase in a single furnace is 0.06%, and about 45Kg of carbon enters the molten steel after calculation. The investigation found that the scrapped 7 heats of molten steel were all caused by cracking, falling off, and falling off of the graphite electrode hole wall when the Φ500mm UHP ultra-high power electrode was used at the joint connection part. Steel manufacturers require graphite electrode manufacturers to improve the production formula of graphite electrodes in a short period of time to meet the actual requirements of producing low carbon steel.

[0113] Through the analysis of ...

Embodiment 2

[0163] A steel factory has 3 electric furnaces to produce plain carbon steel. The graphite electrode used is: Φ550mm UHP ultra-high power graphite electrode. Electric furnace transformer 60MVA, maximum secondary current 50KA, maximum secondary voltage 846V, all scrap steel smelting. The graphite electrode procurement method of the steel plant is: cash plus consumption lump sum (the cost assessment index of steel electrode per ton is 54 yuan / t, and the consumption of steel electrode per ton is 2.15kg / t). In order to develop users, the company provides 15 Φ550mm UHP ultra-high power graphite electrodes for testing. Experimental results The consumption of Φ550mm UHP ultra-high power graphite electrode exceeds the given index.

[0164] Through the investigation of the use of Φ550mm UHP ultra-high power graphite electrodes in steel mills, according to the on-site tracking data, the main problems that caused the consumption index of Φ550mm UHP ultra-high power graphite electrodes ...

Embodiment 3

[0221] A 150tEBT ultra-high power DC furnace in a steel plant uses a Φ700mm UHP ultra-high power graphite electrode. The furnace transformer is 100MVA, the maximum secondary current is 120KA, and the maximum secondary voltage is 670V. As the target user company is ready to develop.

[0222] Investigation on the use of graphite electrodes in steel mills: the electric furnace uses water-cooled steel rods as the anode system of the electric furnace, and the Φ700mmUHP ultra-high power graphite electrode is used as the cathode; the electric furnace uses the Φ700mmUHP ultra-high power graphite electrode as the cathode, and the Φ700mmUHP ultra-high The electrode is consumed in a concave state under the action of the plasma arc. In actual production, the cracking of the graphite electrode is almost accompanied by the whole smelting process; The connection part is 1.5-1.8 meters away from the molten steel, and the electrode will also break under the action of thermal stress; the resid...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Density | aaaaa | aaaaa |

| Density | aaaaa | aaaaa |

| Density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com