Loofah sponge charcoal powder, loofah sponge charcoal-based foam material and application thereof and pillow

A technology of loofah powder and foaming material, which can be used in applications, pillows, household appliances, etc., can solve the problems of easy breeding of mites and bacteria, poor ventilation and moisture dissipation, easy tearing, etc., and achieves good temperature and humidity regulation, not easy to run off. , Improve the effect of interface bonding strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

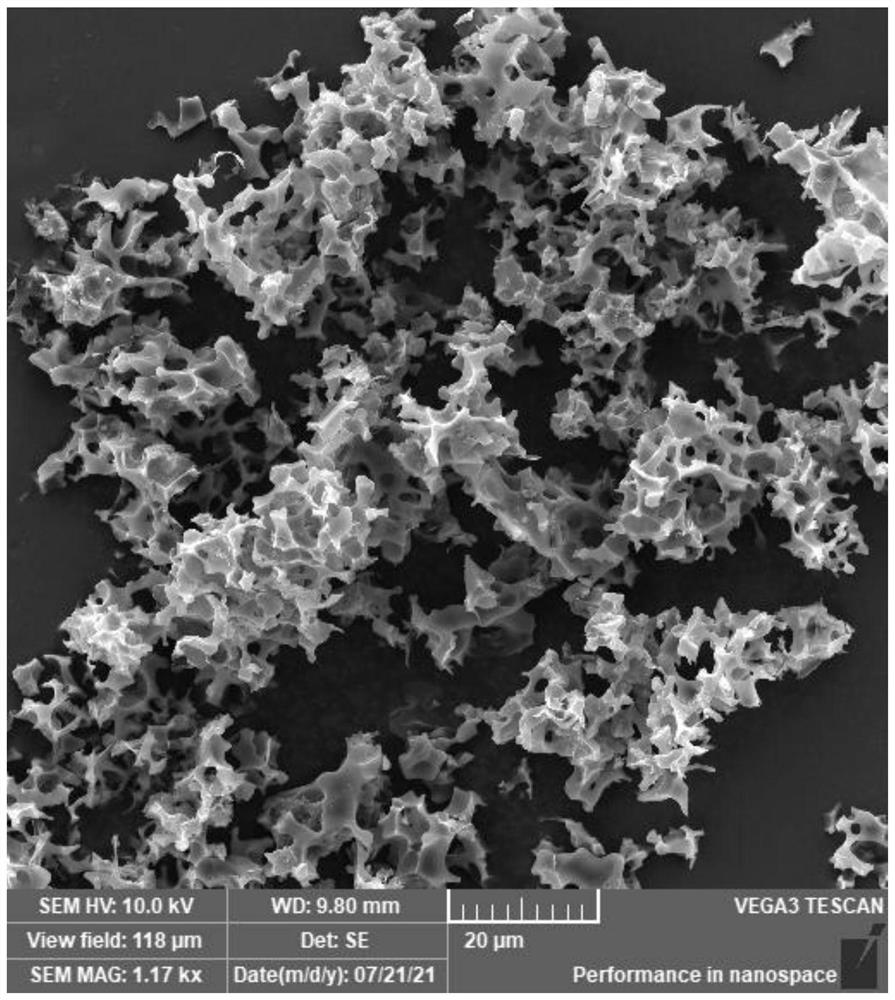

[0056] A kind of loofah charcoal powder of the present embodiment, the preparation method is as follows:

[0057] (1) Preparation of loofah powder:

[0058] Take the dried loofah processing residue (the discarded loofah scraps from the natural columnar loofah processing process) and clean it; after cleaning to remove dust and a small amount of residual loofah seeds, put it in a drying oven at 80°C and dry it to constant weight. Pulverize with a high-speed pulverizer again, sieve and collect loofah powder with 60 mesh standard inspection sieves.

[0059] (2) Activation of loofah:

[0060] The loofah powder obtained in (1) is mixed with an activator in a ratio of 1:2 (the activator is ZnCl 2 with AlCl 3 According to the mass ratio of 1:1 mixed molten salt), and placed on a magnetic stirrer to stir for 5h, vacuum filtration and separation.

[0061] (3) Preparation of loofah charcoal powder:

[0062] ① Fill the activated loofah powder into the quartz boat, send it into the tu...

Embodiment 2

[0066] A kind of loofah carbon-based foaming material of the present embodiment, the preparation method is as follows:

[0067] (1) Preparation of loofah powder:

[0068] With embodiment 1;

[0069] (2) Activation of loofah:

[0070] With embodiment 1;

[0071] (3) Preparation of loofah charcoal powder:

[0072] With embodiment 1;

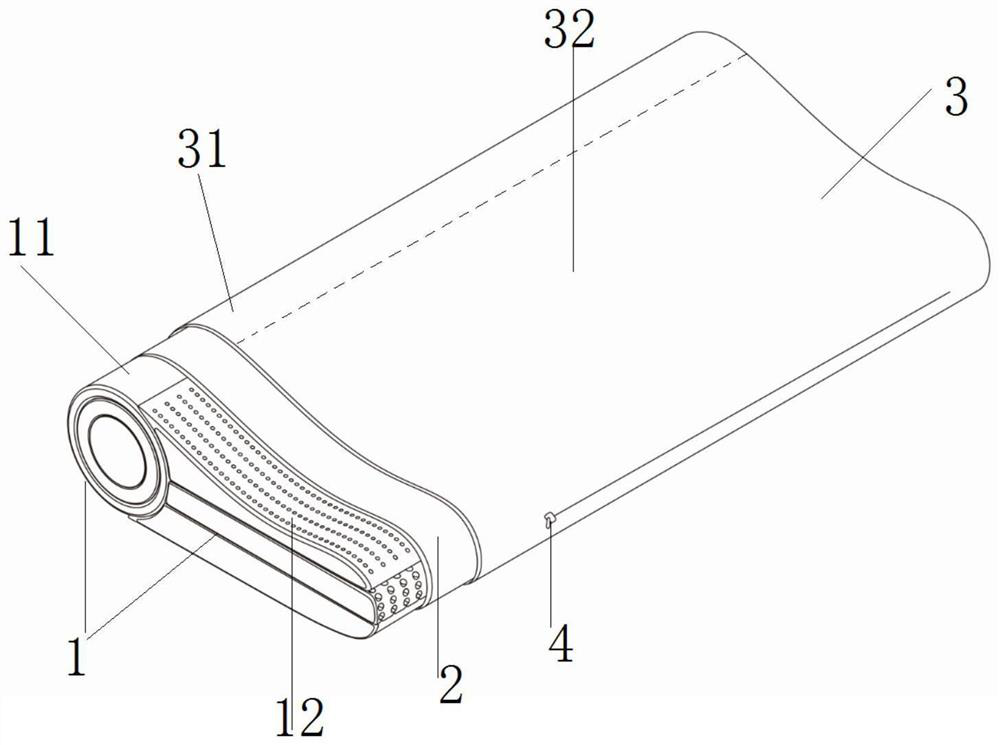

[0073] (4) Preparation of loofah carbon-based memory foam sponge:

[0074] ① Preparation of chemical reagents:

[0075] Component A: 10 parts of loofah activated carbon powder prepared in step (3), 10 parts of polyester polyol, 162140 parts of polyether polyol, 20 parts of slow rebound polyether polyol 307, 15 parts of polyether polyol 3630 , 1 part of chemical blowing agent, 1.5 parts of foam stabilizer, 0.5 part of antioxidant, 1 part of catalyst, and 1 part of surfactant.

[0076] Component B: 30 parts of diphenylmethane diisocyanate MDI.

[0077] ② Stir component A with an adjustable speed mixer at a speed of 2000r / min for 2 minutes, th...

Embodiment 3

[0081] This example is used to verify the effect of different loofah activated carbon additions on the performance of loofah carbon-based memory foam sponge materials.

[0082] Method: Mix 0, 10, 15, 20, 30 parts of loofah activated carbon powder with other components (the addition amount of other components is the same, and refer to Example 2) to prepare corresponding loofah carbon-based memory foam Sponge (refer to Example 2 for the preparation method), and measure according to GB / T 6344-2008, GB / T 6670-1997, GB / T 10808-2006, ASTM D3574, GB / T31402-2015 and HG-T 3689-2014 respectively The mechanical properties, air permeability, antibacterial properties and yellowing resistance of loofah carbon-based memory foam sponge materials are shown in Table 1.

[0083] Table 1 Luffa carbon-based memory foam material performance test results

[0084]

[0085] As can be seen from Table 1, compared with the memory sponge without adding luffa activated carbon powder, the loofah charcoa...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size (mesh) | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com