Polylactic acid dielectric thin film and application thereof as well as method for preparing polylactic acid dielectric thin film and application of method

A polylactic acid and dielectric technology, applied in the field of film capacitor energy storage, can solve the problems of low energy density, low charge and discharge efficiency, low energy energy density, poor thermal stability, etc., and achieve simple equipment requirements, light weight, and good thermal stability Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0076] Weigh 0.1g of poly-d-lactic acid powder and add it to 20mL of dichloromethane solvent, stir until the solid particles of poly-d-lactic acid are completely dissolved, cast the stirred solution on a clean flat mold, and let the solvent cool at 25°C Slowly volatilize and dry for 20 hours to obtain the initial film material.

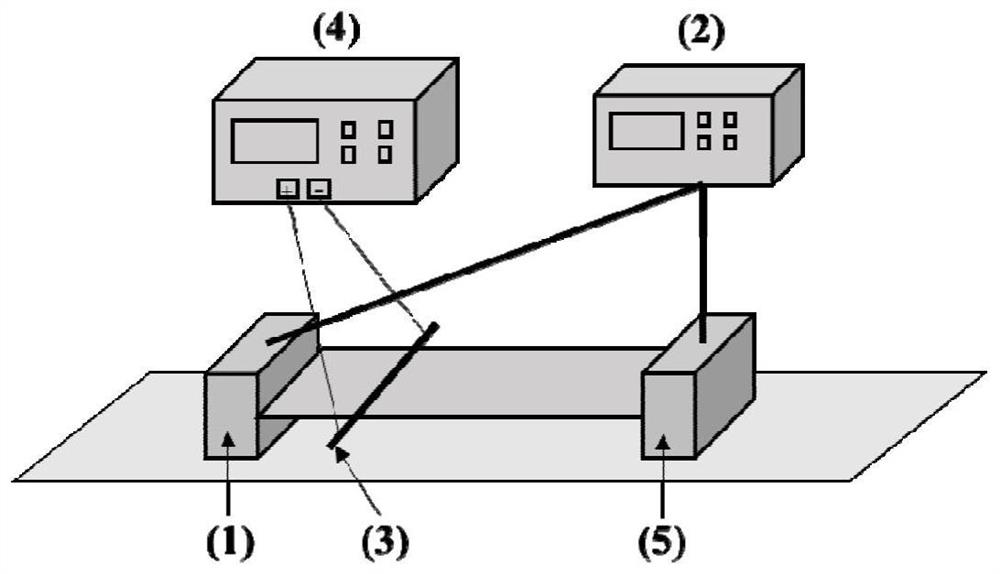

[0077] Fix the two ends of the completely dry initial film material on the first translation platform and the second translation platform respectively, use the heating power supply to adjust the temperature of the heating wire to 90°C, and control the first translation platform and the second translation platform to move in the same direction through the controller Move to achieve stretching of the initial film material, and control the moving rates of the first stage and the second stage so that the moving rate of the first stage 1 is 0.01 mm / s, and the moving rate of the second stage is 0.04 mm / s, stretching the initial film material up to 4 times. ...

Embodiment 2

[0079] Consistent with Example 1, the difference is that the two-way synchronous stretching is used to adjust the moving rate of the first translation stage (1) so that the stretching rate is 0.02mm / s, and the moving speed of the second translation stage (5) is such that The stretching rate was 0.08 mm / s. A polylactic acid dielectric film was obtained. The breakdown field of the polylactic acid dielectric film is 720MV / m, the peak intensity of the (110) crystal plane measured by XRD is 21322, and the peak intensity of the (203) crystal plane is 208.

Embodiment 3

[0081] Same as Example 1, except that the original film was stretched to 3 times. A polylactic acid dielectric film was obtained. The breakdown field of the polylactic acid dielectric film is 680MV / m, the peak intensity of the (110) crystal plane measured by XRD is 18901, and the peak intensity of the (203) crystal plane is 438.

PUM

| Property | Measurement | Unit |

|---|---|---|

| energy density | aaaaa | aaaaa |

| energy density | aaaaa | aaaaa |

| energy density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com