High-strength high-conductivity copper rod and preparation method thereof

A high-conductivity, high-strength technology, applied in conductive materials, conductive materials, conductors, etc., can solve the problems of reduced copper rod strength, low resistivity, high conductivity of copper rods, etc., to improve strength, maintain ductility, and process. The effect of improved performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1-7

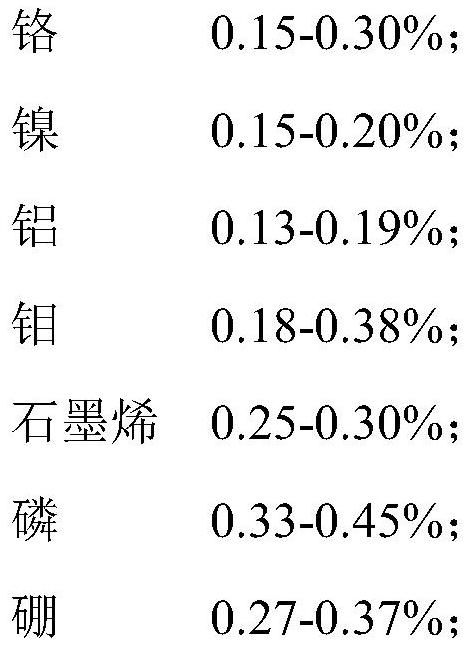

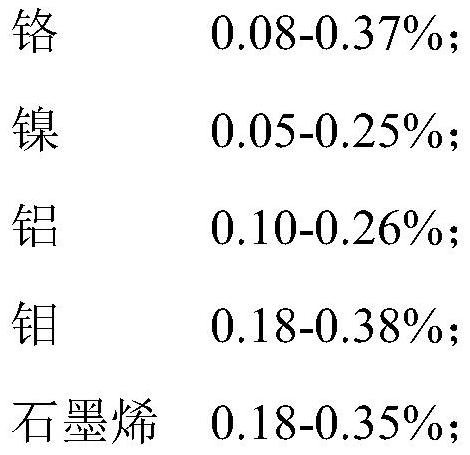

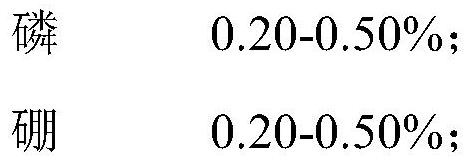

[0026] In Examples 1-7, the weight percentages of the components in the copper rod are shown in Table 1.

[0027] The percentage by weight of each composition of copper rod in the embodiment 1-6 of table 1

[0028]

[0029]

[0030] Wherein, each metal element and non-metal element in this embodiment 1-7 is added in the form of a simple substance with a purity of 99.99%.

[0031] The preparation method of copper rod in the present embodiment 1-6, comprises the following steps:

[0032] S1. Put the copper material in the metal smelting furnace, first evacuate the metal smelting furnace until the pressure in the furnace is lower than 5Pa, then inject helium gas to 1 standard atmospheric pressure, smelt at high temperature until the copper material is completely melted, and keep it for 1h Rear;

[0033] S2. After introducing helium to adjust the air pressure in the metal smelting furnace to 2-2.3 standard atmospheric pressure, add aluminum, nickel, chromium and molybdenum...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com