Metal organic framework foam material as well as preparation method and application thereof

A metal-organic framework and foam material technology, applied in separation methods, chemical instruments and methods, filtration separation, etc., can solve the problems of slowing down the filtration speed, increasing the difficulty and cost of recycling, and difficult to filter microplastics

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

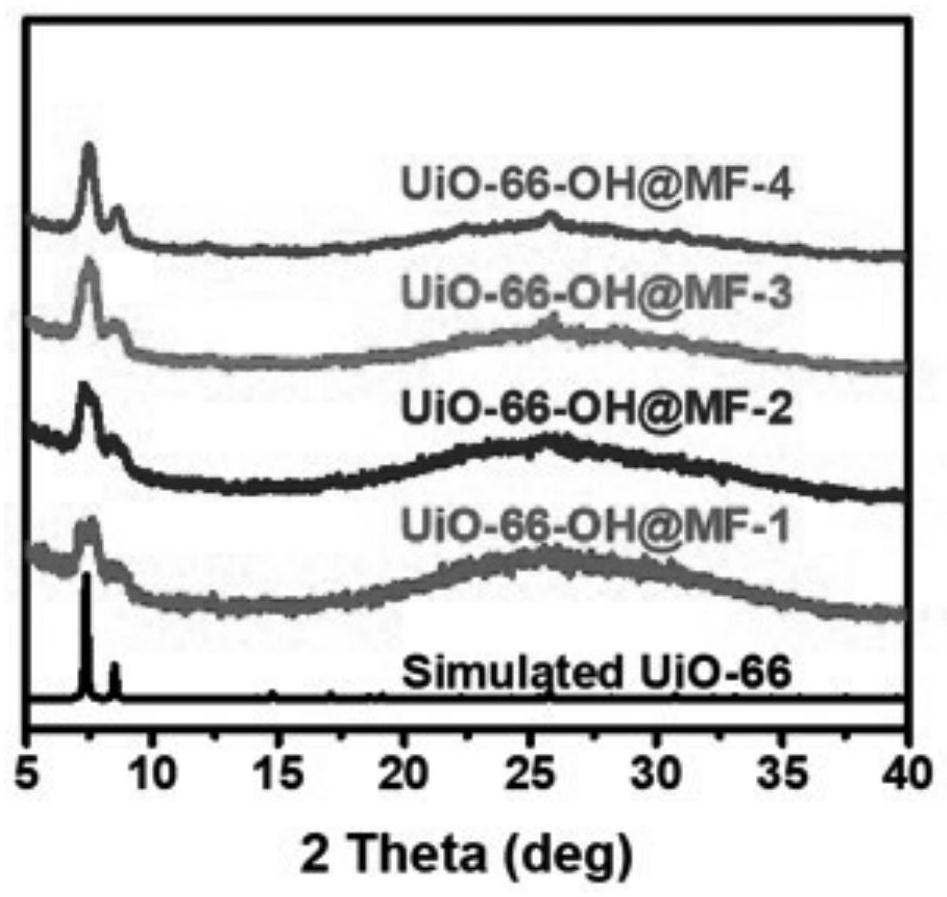

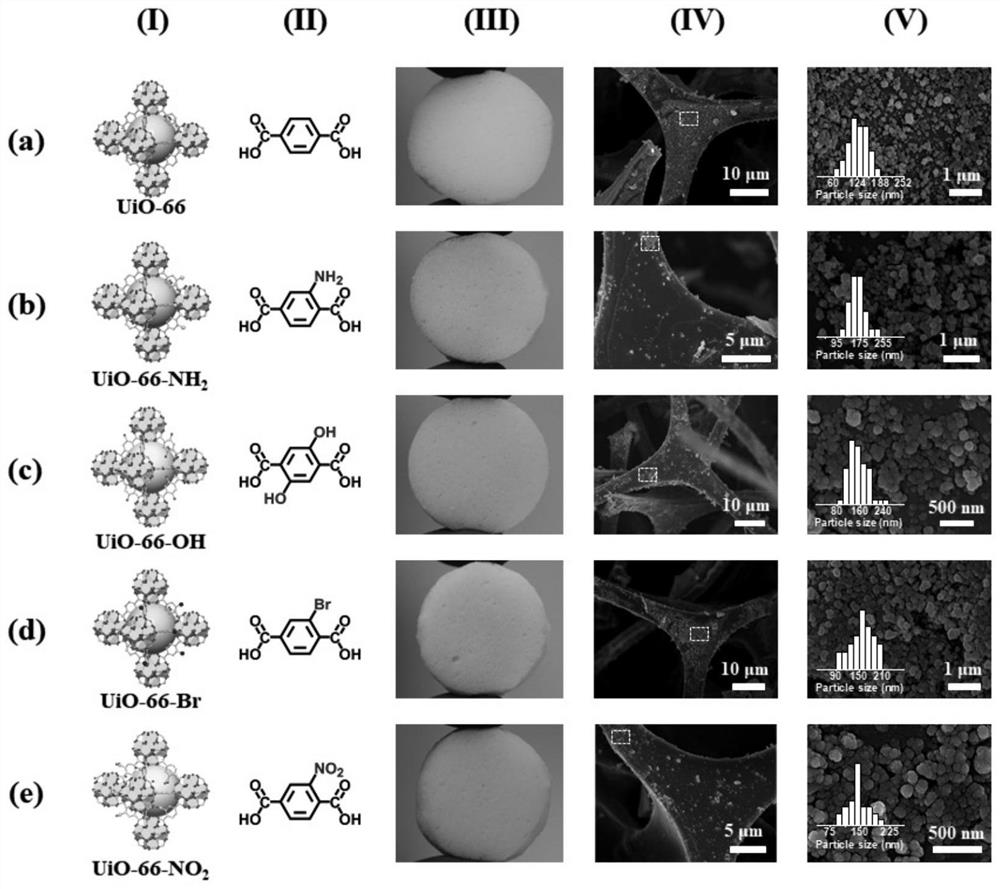

[0026] Under stirring, the ZrCl 4(90 mg, 0.39 mmol) and 2,5-dihydroxyterephthalic acid (77 mg, 0.39 mmol) were added to 30 mL of acetone, followed by sonication for 30 minutes. The mixed solution was transferred to a 50 ml stainless steel autoclave with a piece of MF (melamine formaldehyde resin, about 1 cm in thickness), and heated at 100° C. for 24 hours. After cooling to room temperature, the resulting foam was stirred and washed with acetone and ethanol three times (3 hours each time), and dried under vacuum at 120-150°C for 12 hours to obtain a metal-organic framework foam material containing hydroxyl functional groups UiO- 66-OH@MF. The obtained UiO-66-OH@MF was further characterized, and the UiO-66-OH content in UiO-66-OH@MF was detected to be ~25.4 wt%. The amount of metal salt and ligand was further regulated and increased in equal proportions (0.5-1.5), and a series of foam materials with different loadings were obtained, and the corresponding proportions were name...

Embodiment 2-5

[0029] In Example 1, the precursor material 2,5-dihydroxyterephthalic acid is added and replaced by terephthalic acid (2), 2-aminoterephthalic acid (3), 2-bromoterephthalic acid ( 4) or the precursor material of nitroterephthalic acid (5), then react under the same conditions, process the product, and obtain the corresponding foam material (UiO-66-X@MF, X=H, NH 2 , Br and NO 2 ).

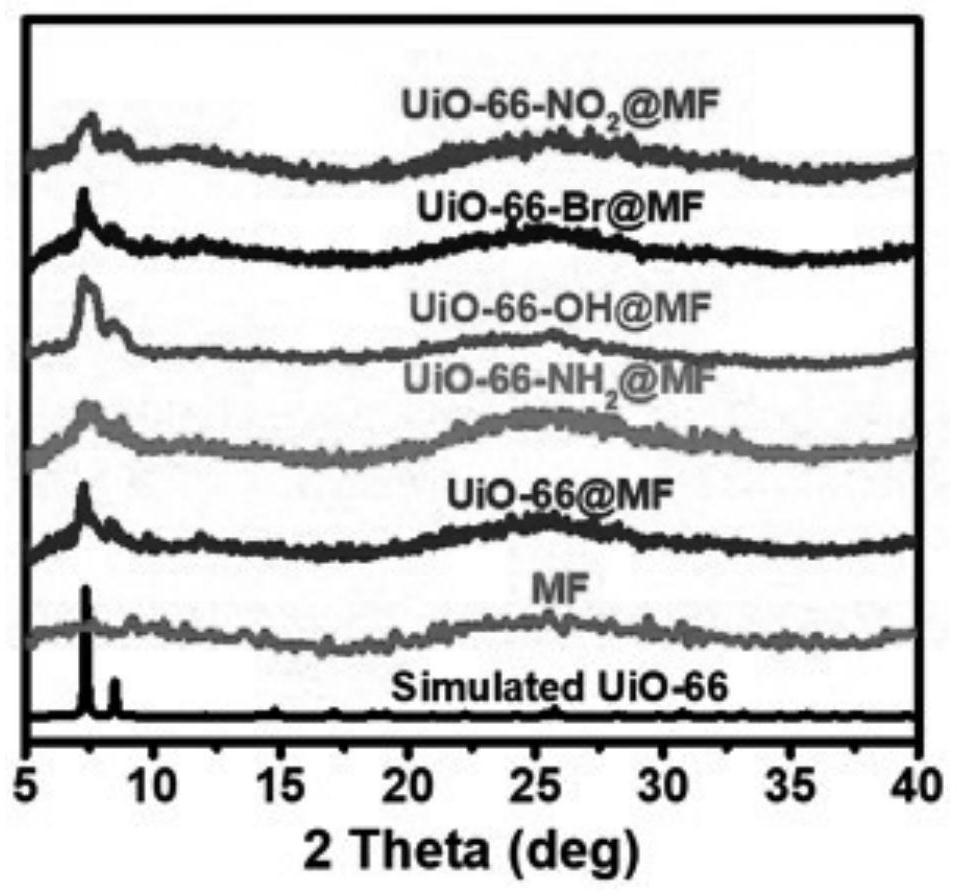

[0030] Powder X-Ray diffraction (PXRD) was used to analyze the structures and morphologies of foam materials with different functional groups. The characterization and simulation diagrams are shown in figure 1 and image 3 .

[0031] The foam material prepared in the above implementation cases 1-5 is developed and applied to the filtration of microplastics:

[0032] The concentration is about 0.01g mL -1 Preparation of simulated microplastic dispersions. Add about 0.2 g of plastic micropowder (including polyvinylidene fluoride PVDF, polymethyl methacrylate PMMA or polystyrene PS) to 200 mL of ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com