Biodegradable composite film for automatic packaging machine and preparation method of biodegradable composite film

An automatic packaging machine, biodegradable technology, applied in packaging, wrapping paper, biological packaging, etc., can solve the problems of difficult recycling, high recycling cost, white pollution, etc., and achieve excellent oxygen and water resistance performance, excellent anti-hydrolysis performance. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

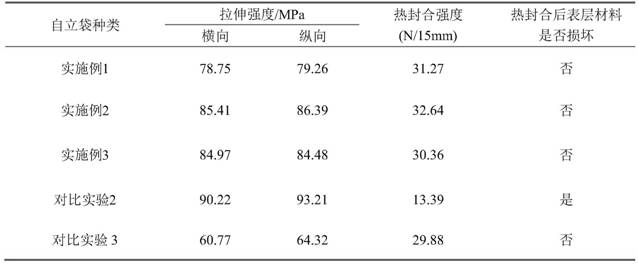

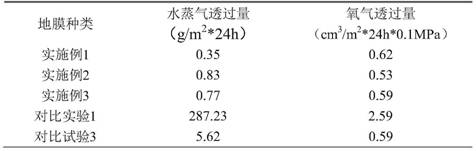

Examples

Embodiment 1

[0035] (1) Polylactic acid (PLA, M W 200000, the optical purity is 96% (L) 95 parts, 5 parts of 2525, 0.5 parts of nano-barium sulfate, and 0.3 parts of white oil are mixed evenly and then added to a parallel twin-screw extruder, melt-blended and air-cooled and pelletized. The melt temperature of the twin-screw extruder is 180 ° C. Prepare Special modified material for the base film layer of the surface layer;

[0036] (2) prepare the surface layer base film with the special modified material for the surface layer base film layer prepared in step (1) through biaxial stretching equipment, the biaxial stretch ratio is 3 * 3, the thickness of the film is 25 microns, and the base layer Corona treatment is performed on one side of the film, and the surface energy of the corona surface after treatment is ≧42dyne;

[0037] (3) The inner surface of the surface base film prepared in step (2) is printed with water-based ink, and the diluent used during printing is a mixture of water ...

Embodiment 2

[0044] (1) Polylactic acid (PLA, M W 200000, the optical purity is 96% (L) 95 parts, 5 parts of 2525, 0.5 parts of nano-barium sulfate, and 0.3 parts of white oil are mixed evenly and then added to a parallel twin-screw extruder, melt-blended and air-cooled and pelletized. The melt temperature of the twin-screw extruder is 180 ° C. Prepare Special modified material for the base film layer of the surface layer;

[0045] (2) prepare the surface layer base film with the special modified material for the surface layer base film layer prepared in step (1) through biaxial stretching equipment, the biaxial stretch ratio is 3 * 3, the thickness of the film is 25 microns, and the base layer Corona treatment is performed on one side of the film, and the surface energy of the corona surface after treatment is ≧42dyne;

[0046] (3) The inner surface of the surface base film prepared in step (2) is printed with water-based ink, and the diluent used during printing is a mixture of water ...

Embodiment 3

[0053] (1) Polylactic acid (PLA, M W 200000, the optical purity is 96% (L) 95 parts, 5 parts of 2525, 0.5 parts of nano-barium sulfate, and 0.3 parts of white oil are mixed evenly and then added to a parallel twin-screw extruder, melt-blended and air-cooled and pelletized. The melt temperature of the twin-screw extruder is 180 ° C. Prepare Special modified material for the surface base film layer;

[0054] (2) prepare the surface layer base film with the special modified material for the surface layer base film layer prepared in step (1) through biaxial stretching equipment, the biaxial stretch ratio is 3 * 3, the thickness of the film is 25 microns, and the base layer Corona treatment is performed on one side of the film, and the surface energy of the corona surface after treatment is ≧42dyne;

[0055] (3) The inner surface of the surface base film prepared in step (2) is printed with water-based ink, and the diluent used during printing is a mixture of water and absolute ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Depth | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com