Recyclable antibacterial waterborne epoxy resin coating and preparation method thereof

A water-based epoxy resin and antibacterial coating technology, which is applied in epoxy resin coatings, antifouling/underwater coatings, coatings, etc., can solve the problems of less cycle times, short action periods, and poor antibacterial effects, and achieve cycle The effect of high frequency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

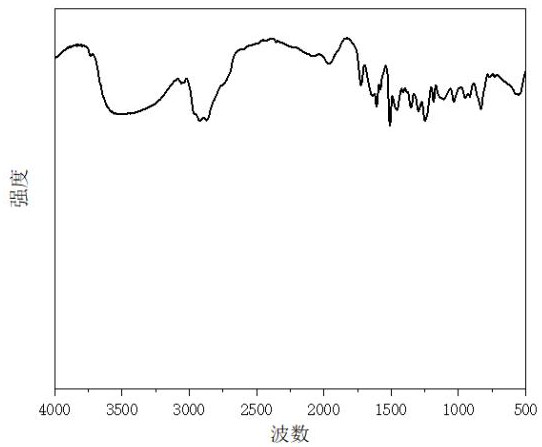

Image

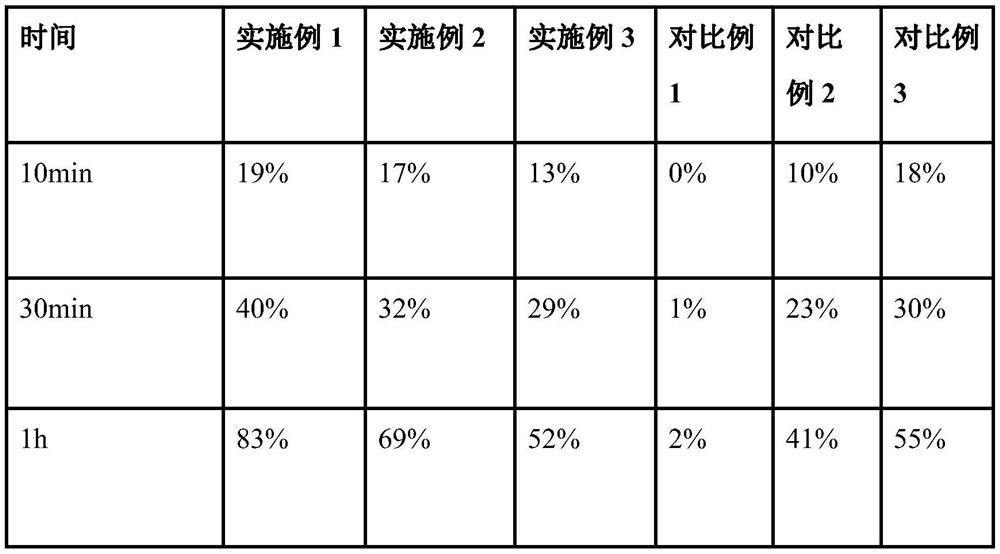

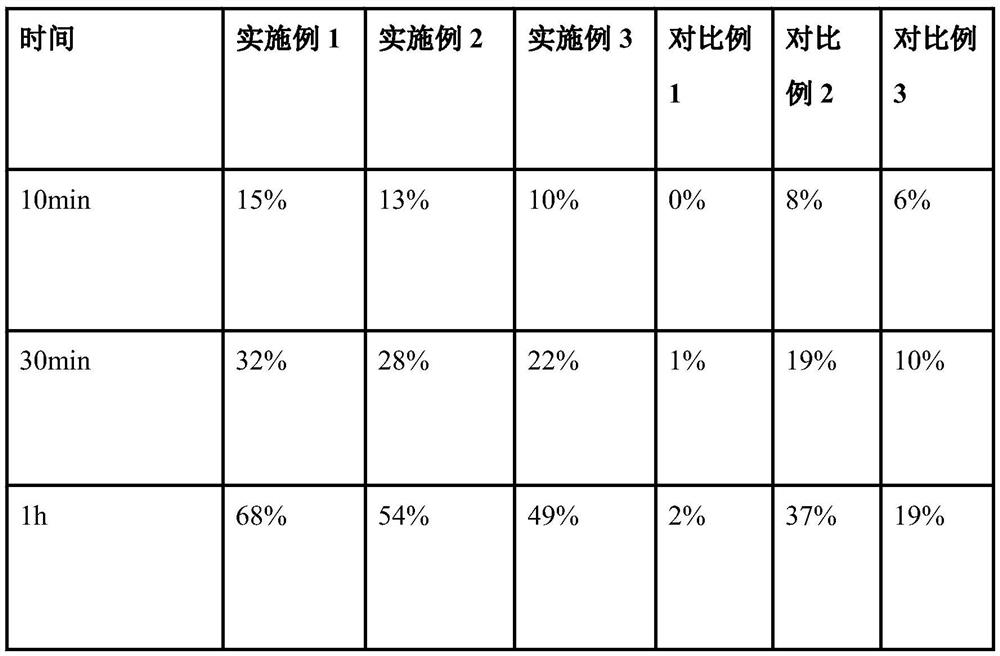

Examples

preparation example Construction

[0030] Preparation of antibacterial photosensitizer:

[0031] (1) Add polyglutamic acid to deionized water and make 400g of 10wt% aqueous solution, add 3g of zinc oxide and 3g of copper oxide in the prepared aqueous solution, add 4g of sulfuric acid while stirring, and take the supernatant after standing for subsequent use;

[0032] (2) 5g of nano-titanium dioxide is added to 10wt% aqueous solution of 500g of ethanol, stirred and added with 0.5g of silane coupling agent KH-550, then heated to 70°C, kept for 2h, then centrifuged, and cleaned with deionized water to obtain improved Titanium dioxide;

[0033] (3) Add 3 g of modified titanium dioxide to 300 g of the supernatant prepared in step (1), and react at 50° C. for 2 h to obtain an antibacterial photosensitizer.

Embodiment 1

[0035]Preparation of water-based antibacterial coating: take 7g of water-based epoxy resin emulsion, 0.1g of polypropylene glycol diglycidyl ether and 0.1g of antibacterial photosensitizer and blend them, then stir at a speed of 1000r / min for 10min through a disperser to obtain a mixed solution 1. Take 1 g of modified styrene-acrylic emulsion and 0.5 g of methylenebisacrylamide saturated solution and stir at a speed of 200 r / min for 10 min to obtain mixed solution 2. After blending mixed solution 1 and mixed solution 2, add 1.3 g of deionized water at 800 r / min. After stirring at a speed of 10 min / min, water-based antibacterial coatings were obtained.

[0036] Preparation of paint film: Take 2g of prepared water-based antibacterial coating and 1.4g of water-based epoxy resin curing agent, stir in a beaker at a speed of 500r / min for 30min at room temperature, and spread evenly on the polished iron plate to ensure the thickness At 100±5μm.

Embodiment 2

[0038] Preparation of water-based antibacterial coating: take 7.5g of water-based epoxy resin emulsion, 0.1g of polypropylene glycol diglycidyl ether and 0.1g of antibacterial photosensitizer and blend them, then stir at a speed of 1000r / min for 10min through a disperser to obtain a mixed solution 1. Take 1.15g of modified styrene-acrylic emulsion and 0.5g of saturated methylenebisacrylamide solution and stir at a speed of 200r / min for 10min to obtain mixed solution 2. After blending mixed solution 1 and mixed solution 2, add 1.15g of deionized water to After stirring at a speed of 800r / min for 10min, a water-based antibacterial coating was obtained.

[0039] Preparation of paint film: Take 2g of prepared water-based antibacterial coating and 1.5g of water-based epoxy resin curing agent, stir in a beaker at a speed of 500r / min for 30min at room temperature, and spread evenly on the polished iron plate to ensure the thickness At 100±5μm.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com