Positive photoresist composition

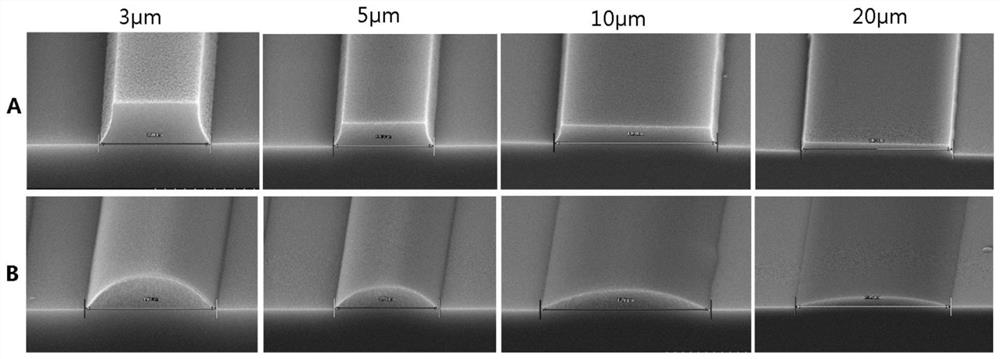

A technology of positive photoresist and composition, which is applied in the field of photoresist, and can solve problems such as substrate edge collapse, poor peripheral circuit area loss, and circuit defects, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0036] Take phenolic resin 15g, photosensitive compound 5g, crosslinking agent 5g, leveling agent 0.05g, adhesion promoter 0.09, solvent 74.86g, phenolic resin, photosensitive compound, crosslinking agent, leveling agent, adhesion promoter The agent is dissolved in a solvent to obtain a positive photoresist composition.

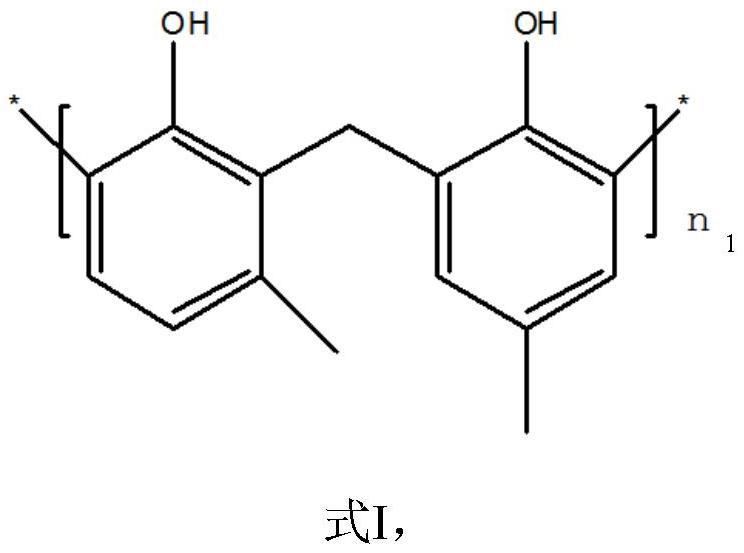

[0037] Phenolic resin, structural formula as shown in formula I, n 1 =170;

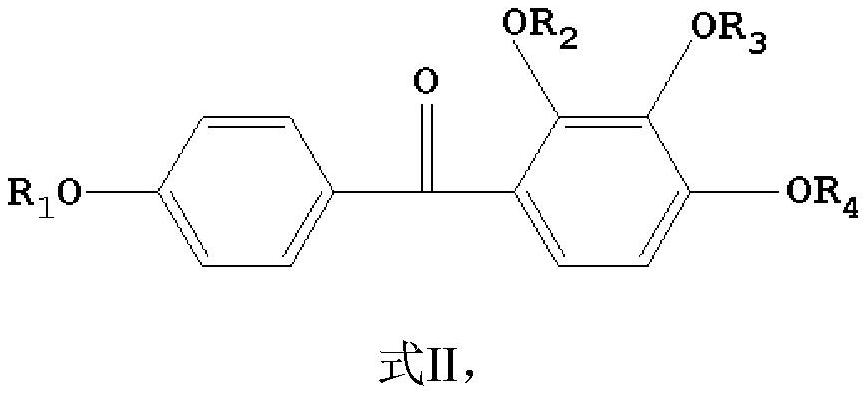

[0038] Photosensitive compound, the structural formula is shown in formula II, R 1 , R 2 , R 3 is a compound of structural formula III, R 4 is hydrogen;

[0039] Cross-linking agent, the structural formula is shown in formula VI;

[0040] Leveling agent, perfluorooctane sulfonyl fluoride;

[0041] Adhesion promoter, polymethyl vinyl ether;

[0042] Solvent, propylene glycol methyl ether acetate.

Embodiment 2-5

[0044] The phenolic resin, photosensitive compound, crosslinking agent, leveling agent, adhesion promoter, solvent, and preparation method are the same as those in Example 1, and the changes of relevant preparation parameters are shown in Table 1.

Embodiment 6

[0046] Phenolic resin, structural formula as shown in formula I, n 1 =85;

[0047] Photosensitive compound, the structural formula is shown in formula II, R 2 , R 3 , R 4 Is the compound of structural formula IV, R 1 is hydrogen;

[0048] Solvent: N-methylpyrrolidone;

[0049] The crosslinking agent, leveling agent, adhesion promoter, and preparation method are the same as in Example 1, and the changes of relevant preparation parameters are shown in Table 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Heat resistance temperature | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com