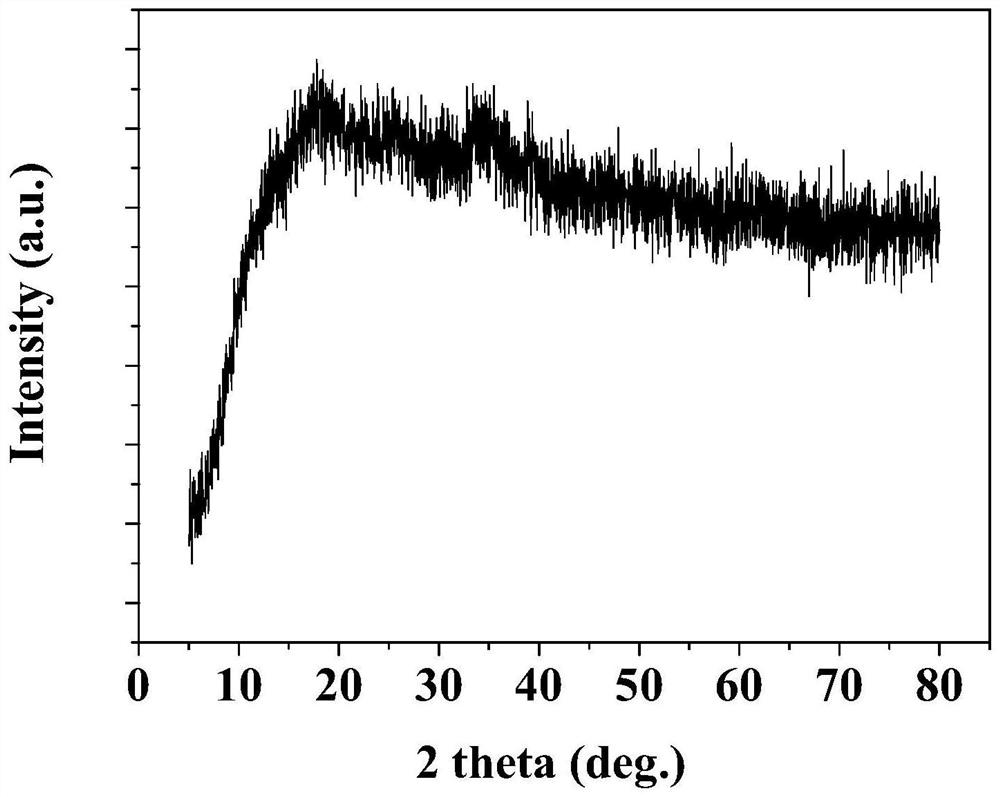

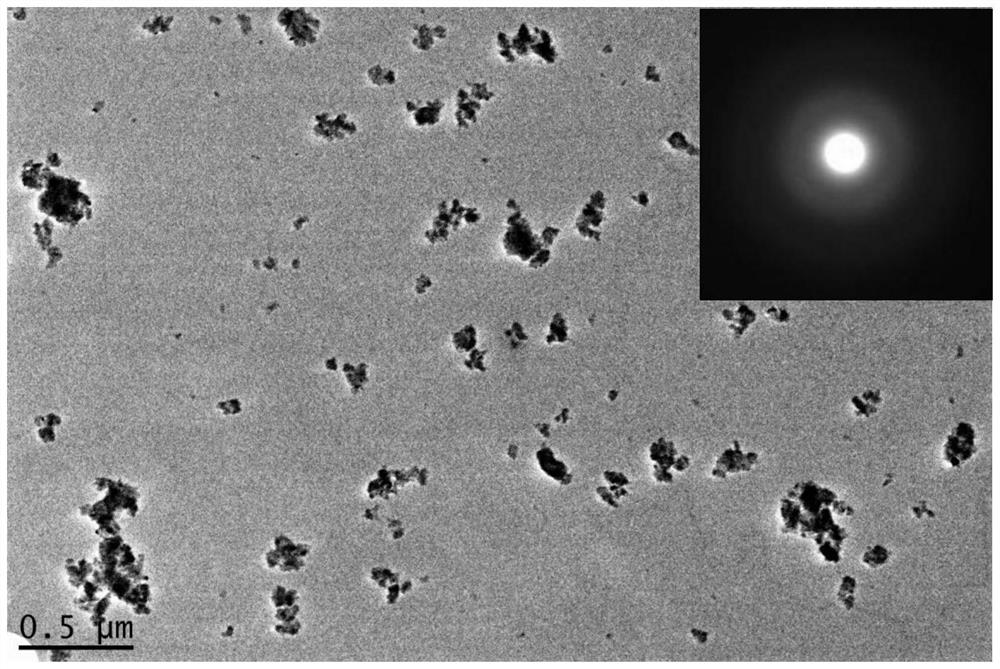

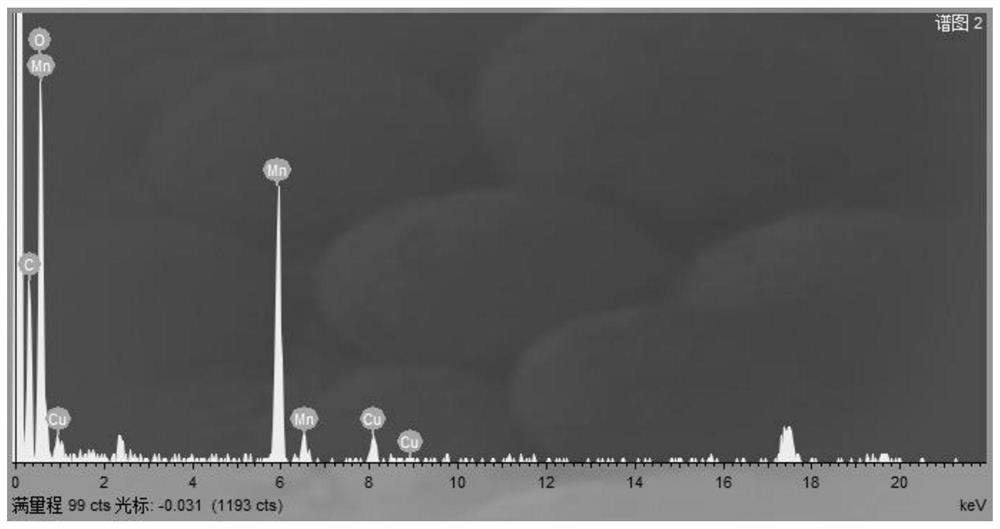

Amorphous CuxMn1-xCO3 catalytic material, preparation method and application of amorphous CuxMn1-xCO3 catalytic material in preparation of acetophenone

A cuxmn1-xco3, catalytic material technology, applied in the field of preparation, amorphous CuxMn1-xCO3 catalytic material, preparation of acetophenone, can solve the problems of complex preparation process, small specific surface area, unfavorable catalytic efficiency, etc., and achieve high catalytic efficiency , the effect of large specific surface area

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0035] The amorphous Cu proposed by the present invention 0.02 mn 0.98 CO 3 The specific preparation process of the catalytic material is as follows:

[0036] (1) In 100mL of water, Cu(NO 3 ) 2 ·6H 2 O and Mn(NO 3 ) 2 ·6H 2 O is configured into a mixed solution with a concentration of 0.2mol / L and 9.8mol / L respectively; in another 100mL of water, (NH 4 ) 2 CO 3 Configured as a solution with a concentration of 10mol / L;

[0037] (2) (NH 4 ) 2 CO 3 The solution is quickly added to the copper-manganese mixed solution, and the precipitate suspension is continuously produced under magnetic stirring;

[0038] (3) Quickly add the precipitation suspension into 200mL liquid nitrogen and freeze for 10min;

[0039] (4) Take the product out of liquid nitrogen, wash with water, filter, and dry in a vacuum oven at 40°C for 12 hours to obtain amorphous Cu x mn 1-x CO 3 catalytic material.

[0040] The above amorphous Cu 0.02 mn 0.98 CO 3 The application of catalytic mate...

Embodiment 2

[0042] The amorphous Cu proposed by the present invention 0.04 mn 0.96 CO 3 The specific preparation process of the catalytic material is as follows:

[0043] (1) In 100mL of water, Cu(NO 3 ) 2 ·6H 2 O and Mn(NO 3 ) 2 ·6H 2 O is configured as a mixed solution, and the concentrations are 0.2mol / L and 3.8mol / L respectively; in another 100mL water, (NH 4 ) 2 CO 3 Configured as a solution with a concentration of 4.0mol / L;

[0044] (2) (NH 4 ) 2 CO 3 The solution is quickly added to the copper-manganese mixed solution, and the precipitate suspension is continuously produced under magnetic stirring;

[0045] (3) The precipitated suspension was quickly added to 200 mL of liquid nitrogen and frozen for 15 min;

[0046] (4) Take the product out of liquid nitrogen, wash with water, filter, and dry in a vacuum oven at 40°C for 12 hours to obtain amorphous Cu x mn 1-x CO 3 catalytic material.

[0047] The above amorphous Cu 0.04 mn 0.94 CO 3 The application of catalyti...

Embodiment 3

[0049] The amorphous Cu proposed by the present invention 0.06 mn 0.94 CO 3 The specific preparation process of the catalytic material is as follows:

[0050] (1) In 100mL of water, Cu(NO 3 ) 2 ·6H 2 O and Mn(NO 3 ) 2 ·6H 2 O is configured as a mixed solution, and the concentrations are 0.2mol / L and 3.1mol / L respectively; in another 100mL water, (NH 4 ) 2 CO 3 Configured as a solution with a concentration of 3.3mol / L;

[0051] (2) (NH 4 ) 2 CO 3 The solution is quickly added to the copper-manganese mixed solution, and the precipitate suspension is continuously produced under magnetic stirring;

[0052] (3) The precipitated suspension was quickly added to 200 mL of liquid nitrogen and frozen for 20 min;

[0053] (4) Take the product out of liquid nitrogen, wash with water, filter, and dry in a vacuum oven at 40°C for 12 hours to obtain amorphous Cu x mn 1-x CO 3 catalytic material.

[0054] The above amorphous Cu 0.06 mn 0.94 CO 3 The application of cataly...

PUM

| Property | Measurement | Unit |

|---|---|---|

| size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com