Carbon-carbon composite material ring for hot pressed sintering and preparation method thereof

A carbon-carbon composite material and hot-pressing sintering technology, which is applied to the carbon-carbon composite material ring for hot-pressing sintering and its preparation field, can solve the problems of short life, early deformation of the carbon-carbon composite material ring, and can not be completely filled, etc. Excellent performance, high tensile strength and safe use

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

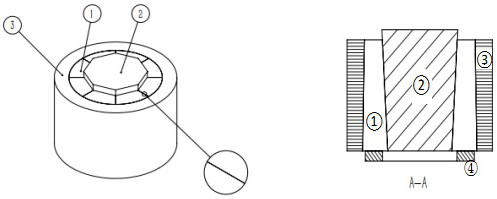

[0034] A method for preparing a carbon-carbon composite ring for hot pressing and sintering comprises the following steps:

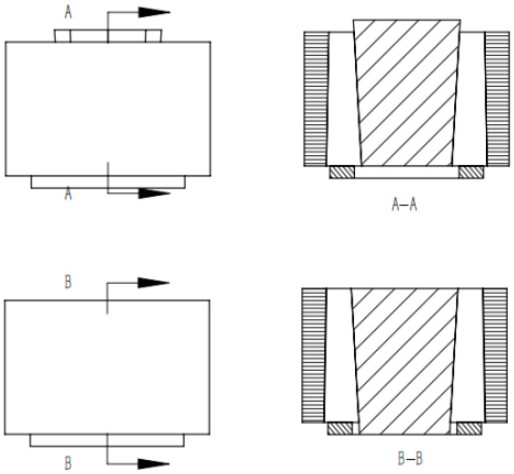

[0035] (1) Make a steel cylinder core with a taper of 2° (large diameter 757.5mm, small diameter 740mm, height 500mm), and wrap graphite paper on the surface of the steel cylinder. Then wrap 20-30 layers of carbon fiber cloth impregnated with phenolic resin on the graphite. Then wind T700. 12K carbon fiber yarn, the tension is controlled at 10 kg. The pitch of the carbon fiber yarn winding process is 15mm, and after the winding thickness is 3mm, the carbon fiber cloth is rewound 20-30 layers, and the winding is repeated in this way. During the winding process, more carbon fiber cloth and carbon fiber yarn are wound on the side of the trail under conscious control. In order to gradually reduce the taper of the external diameter of the winding, it is beneficial for the winding of the carbon fiber cloth to be smooth. Repeated winding of carbon fiber cloth...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| compressive strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com