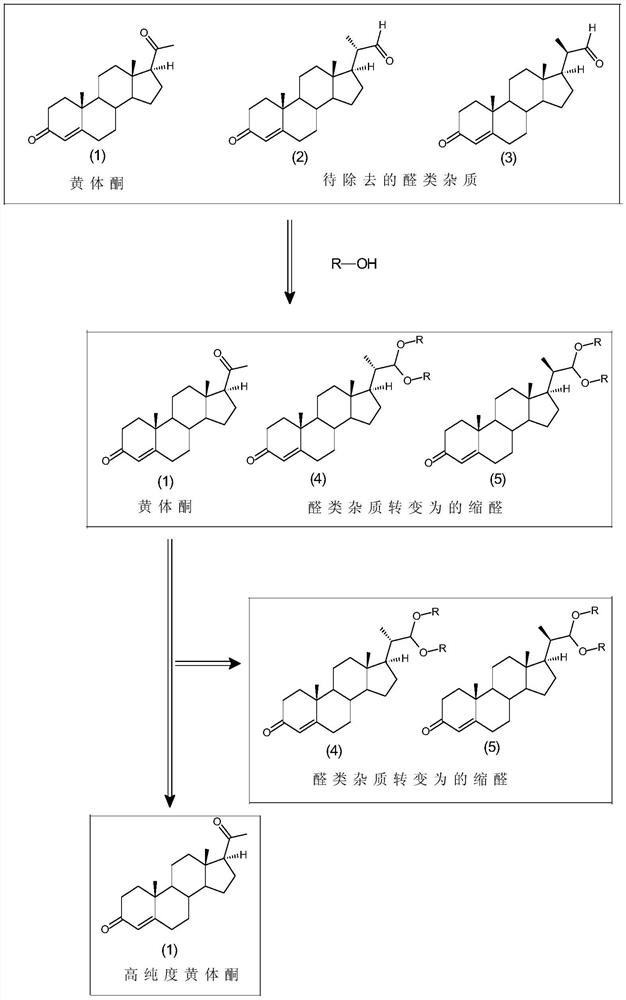

Impurity removal method of progesterone

A progesterone and impurity technology, which is applied in the field of preparation and processing of steroid hormone drugs, can solve the problem of reducing to less than 0.6%, and achieve the effects of low equipment requirements, mild reaction, and low cost input

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

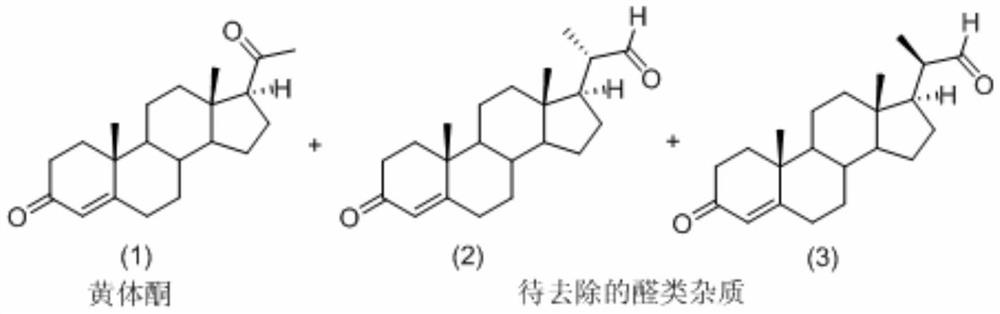

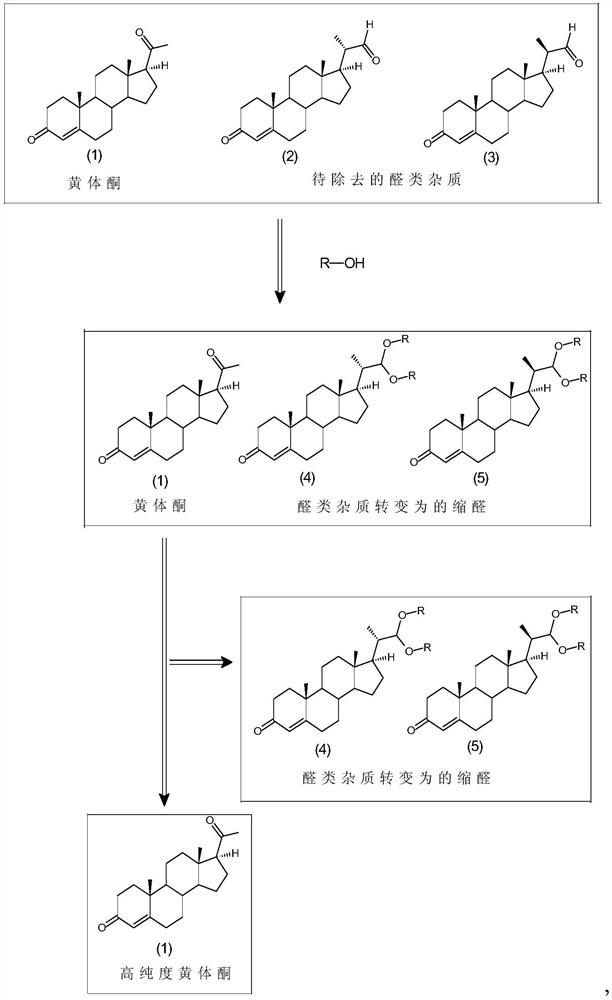

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0024] The impurity removal method of embodiment 1 progesterone

[0025] Completely dissolve 50g of progesterone crude product (containing 2% impurity aldehyde) in 150ml of methanol, add 0.25g of p-toluenesulfonic acid, control the temperature at 60°C and stir for reaction. Thin layer chromatography shows that the reaction of aldehyde impurities is complete, add 0.25ml of triethylamine Neutralize the amine, concentrate the methanol, add 250ml methyl tert-butyl ether, cool down to -20°C, filter, and dry to obtain 46.3g of high-purity progesterone, the product yield is 92.6%, the product melting point is 129.2~130.0°C, HPLC Content 99.7%, impurity aldehyde content 0.12%.

Embodiment 2

[0026] The impurity removal method of embodiment 2 progesterone

[0027] 50g of crude progesterone (containing 3% impurity aldehyde) was completely dissolved in 500ml of methanol, 0.5g of malonic acid was added, and the temperature was controlled at 40°C to stir the reaction. Thin layer chromatography showed that the reaction of aldehyde impurities was complete, and 0.5ml of pyridine was added to neutralize , concentrated methanol, added 50ml ethyl acetate, cooled to 5°C, filtered, dried to obtain 45.5g of high-purity progesterone, product yield 91.0%, product melting point 128.8~130.0°C, HPLC content 99.5%, impurity aldehyde content 0.17%.

Embodiment 3

[0028] The impurity removal method of embodiment 3 progesterone

[0029] 50g of crude progesterone (containing 2.5% impurity aldehyde) was completely dissolved in 1500ml of ethanol, 2.5g of pyridinium hydrobromide was added, and the temperature was controlled at 20°C to stir the reaction. Thin layer chromatography showed that the reaction of aldehyde impurities was complete, and 2.5ml of piperidine was added. Neutralize with pyridine, concentrate to remove ethanol, add 25ml of acetone, cool to -10°C, filter and dry to obtain 45.8g of high-purity progesterone, product yield 91.6%, product melting point 129.1-130.2°C, HPLC content 99.6%, impurity Aldehyde content 0.15%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com