Nitrogen-phosphorus-silicon ternary halogen-free synergistic flame-retardant thermoplastic elastomer and preparation method thereof

A thermoplastic elastomer, synergistic flame retardant technology, applied in the field of thermoplastic elastomer and its preparation, can solve the problems of complex processing process and difficult large-scale industrialization

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

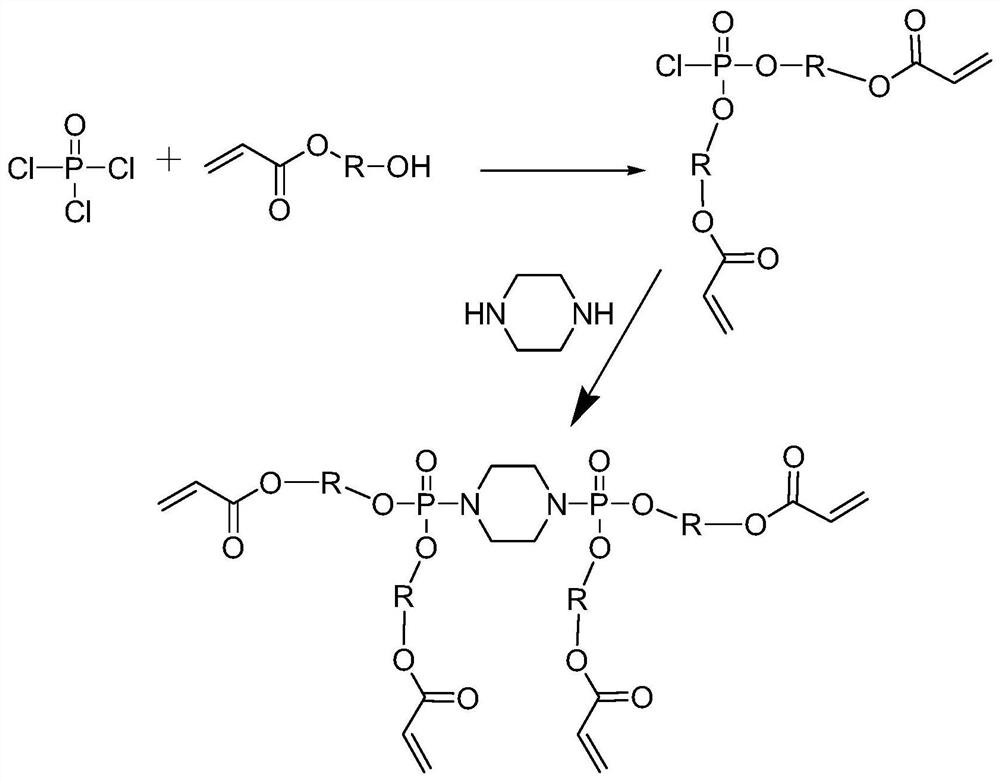

Method used

Image

Examples

Embodiment 1

[0050] Phosphorous and nitrogen-containing tetrafunctional acrylate prepared with hydroxyethyl acrylate, block styrene copolymer, extender oil, polypropylene, maleic anhydride grafted styrene block copolymer, silicone polyurethane block copolymer , thermoplastic polyurethane, lubricant, stabilizer, silicone masterbatch and other components were mixed in a high-speed mixer for 30 minutes according to the following weight ratio, mixed evenly, and then mixed in a low-speed mixer for 20 minutes, and the evenly mixed material was fed by a metering feeder Put it into a twin-screw extruder, set the temperature at 170°C-200°C, set the speed of the host at 320rpm / min, and set the frequency of the feeder at 28Hz. The mixed raw materials are obtained through high-temperature shearing, melting, plasticizing, mixing, and water ring cutting of a twin-screw extruder. The specific components are as follows:

[0051]

Embodiment 2

[0053] Granulate according to the manufacturing process in Example 1 and the following raw material weight ratio.

[0054]

Embodiment 3

[0056]

PUM

| Property | Measurement | Unit |

|---|---|---|

| viscosity | aaaaa | aaaaa |

| viscosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com