Cationic UV-curable glass ink, product produced by using same and production process thereof

A technology of glass ink and production process, which is applied in the field of ink and coating, which can solve the problems of poor glass adhesion, poor water resistance, inconsistent coating thickness, etc., to achieve outstanding outdoor weather resistance and water resistance, excellent glass adhesion, printing good stability effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

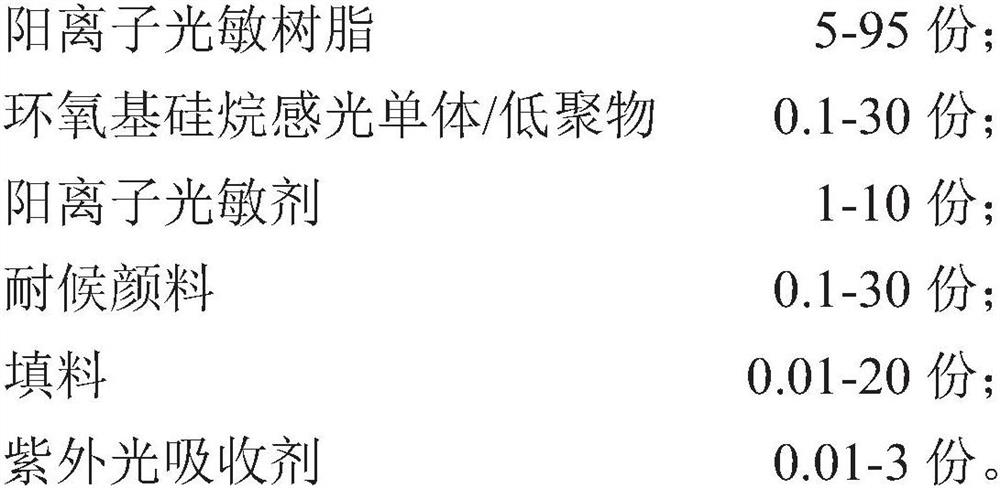

[0054] A kind of cationic UV curable glass ink, the total weight is based on 100 parts, and the composition is as follows:

[0055]

[0056] Mix the above-mentioned components uniformly in proportion, apply by screen printing or other methods, and print a golden yellow UV coating with a thickness of 20 microns. First preheat at low temperature, then perform UV surface curing, and finally heat to post-cure the coating. Preheating conditions: 35°C, 1 minute, UV light energy 800 mJ / cm2, curing conditions after IR heating: 180°C, 3 minutes.

[0057] The UV curable coating has excellent weather resistance and water resistance, and the cured film has good adhesion to glass.

Embodiment 2

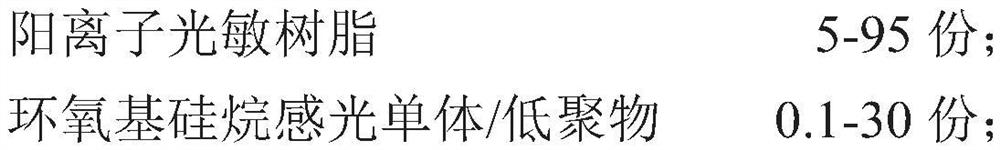

[0059] A kind of cationic UV curable glass ink, the total weight is based on 100 parts, and the composition is as follows:

[0060]

[0061] Mix the above-mentioned components uniformly in proportion, apply by screen printing or other methods, and print a blue transparent UV coating with a thickness of 25 microns. First preheat at low temperature, then perform UV surface curing, and finally heat to post-cure the coating. Preheating conditions: 35°C, 1 minute, UV light energy 1000 mJ / cm2, curing conditions after IR heating: 160°C, 7 minutes.

[0062] The UV curable coating has excellent weather resistance and water resistance, and the cured film has good adhesion to glass.

Embodiment 3

[0064] A kind of cationic UV curable glass ink, the total weight is based on 100 parts, and the composition is as follows:

[0065]

[0066] The above-mentioned components were mixed evenly in proportion, and coated by screen printing or other methods to obtain a silver UV coating with a thickness of 25 microns. First preheat at low temperature, then perform UV surface curing, and finally heat to post-cure the coating. Preheating conditions: 35°C, 1 minute, UV light energy 1300 mJ / cm2, curing conditions after IR heating: 140°C, 10 minutes.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com