Microcapsule formaldehyde remover, preparation method thereof and water-based damping coating

A technology of formaldehyde remover and damping coating, which is applied in the field of coatings, can solve the problems of sharp impact noise on wooden floors, endangering health, and high requirements for ground sound insulation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0051] The present invention also provides a preparation method of the microcapsule formaldehyde remover, comprising: S1) preparation of core material aqueous solution: mixing amino acids, tea polyphenols, adsorbents, imidazole compounds and organic amine compounds in water to obtain the core material material aqueous solution; oil phase preparation: mix and heat emulsifier, dispersant and sweet almond oil to obtain oil phase; wall material solution preparation: mix β-cyclodextrin crosslinked polymer with water to obtain wall material solution; S2) Mix and stir the core material aqueous solution and the wall material solution, add the oil phase and continue to stir to obtain a microcapsule formaldehyde remover solution; S3) spray-dry the microcapsule formaldehyde remover solution to obtain a microcapsule formaldehyde remover. Wherein, the preparation of the core material aqueous solution, the oil phase and the wall material solution is not in any order.

[0052] The present in...

Embodiment 1

[0085] 1.1 Preparation of core material solution: add 1 part of arginine, 0.5 part of histidine, 2 parts of urea, 1 part of imidazole, 1.5 parts of tea polyphenols, and 1 part of triethanolamine into 20 parts of pure water and mechanically stir at 800 rpm, Stir for 20 minutes, slowly add 6 parts of bamboo charcoal powder (particle size: 2000 mesh), 200 rpm, and stir for 30 minutes to obtain the required core material solution;

[0086] 1.2 Preparation of wall material solution: Add 15 parts of β-cyclodextrin cross-linked polymer into 45 parts of pure water, and mechanically stir at 500 rpm for 1 hour to obtain the required wall material solution;

[0087] 1.3 Oil phase preparation: weigh 3 parts of sweet almond oil, 3 parts of Span 80, and 2 parts of polyvinyl alcohol, heat to 70°C, and mechanically stir at 600 rpm for 30 minutes to obtain the required oil phase;

[0088] 1.4 Add the core material solution to the wall material solution, stir mechanically at 600 rpm for 30 minu...

Embodiment 2~7 and comparative example 1

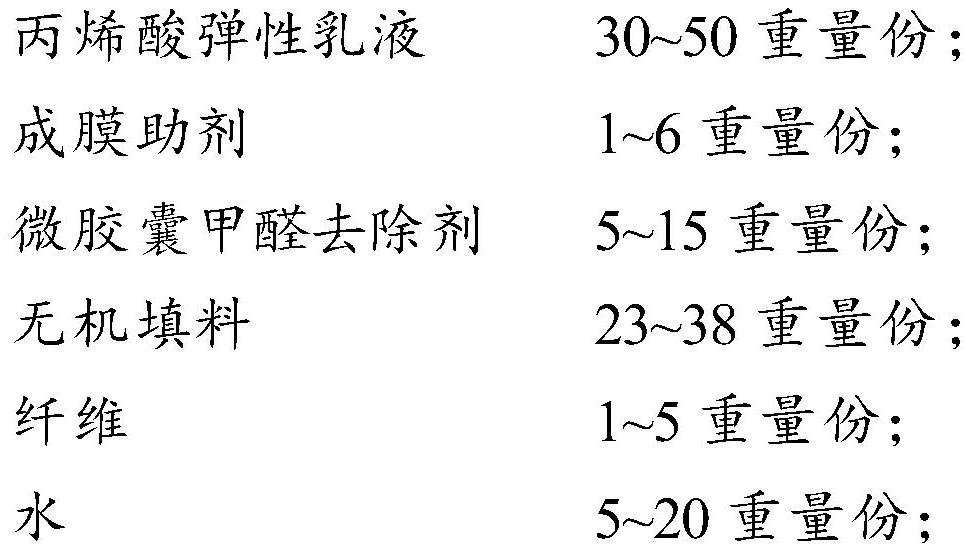

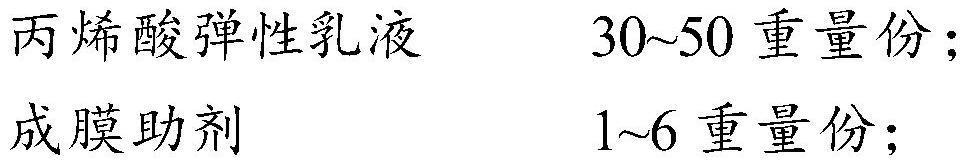

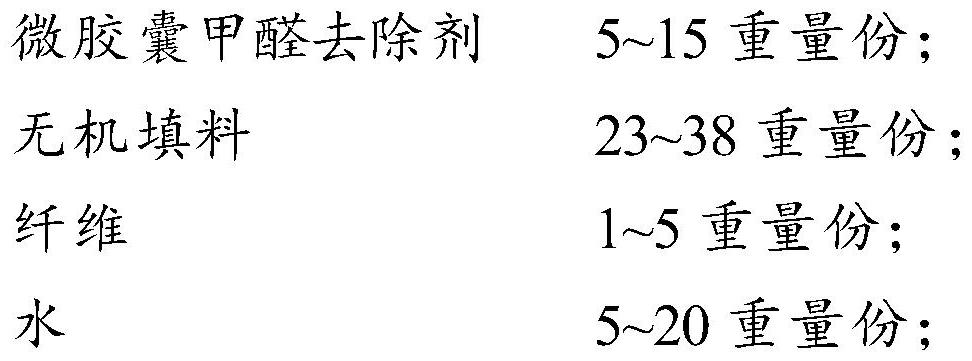

[0091] According to the composition of the components in Table 1, add the specified amount of pure water into the stirring tank, and then add the specified amount of acrylic emulsion, film-forming aid, dispersant, anti-mold and fungicide, turn on the mixer, stir for 30 minutes, and the mixer speed is 600 Rev / min; Slowly add the microcapsule formaldehyde remover obtained in Example 1, floating beads, diatomaceous earth, mica powder, wood fiber, stirring time 1h, stirrer rotating speed 400 rev / min; Add defoaming agent, continue to stir slowly for 10 minutes at a stirring speed of 100-200 rpm, remove the air bubbles in the paint, and then obtain the water-based damping paint for building floors.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com