Ultrahigh molecular weight polyethylene fiber reinforced material and preparation method thereof

An ultra-high molecular weight, polyethylene fiber technology, applied in the field of materials, can solve the problems of lack of active chemical groups in ultra-high molecular weight polyethylene fibers, difficult to achieve interface mechanical properties, and poor interface bonding properties.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

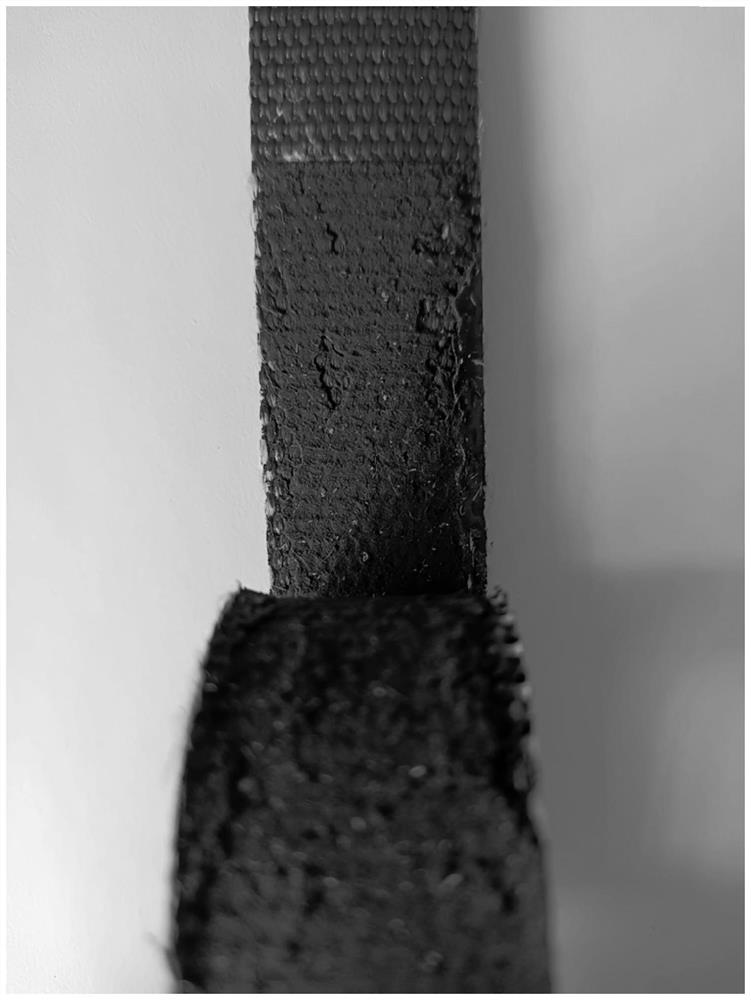

Image

Examples

Embodiment 1

[0055] A method for preparing an ultra-high molecular weight polyethylene fiber reinforced material, comprising dipping in three baths, using the first bath dipping solution, the second bath dipping solution and the third bath dipping solution for dipping treatment respectively;

[0056] The total mass concentration of the first bath dipping is 4%, and the pH value is 5;

[0057]The total mass concentration of the second bath dipping glue is 18%, and the pH value is 9;

[0058] The total mass concentration of the dipping in the third bath is 16%, and the pH value is 9.

[0059] First bath dipping comprises following mass parts raw material:

[0060]

[0061] The preparation method of the first bath dipping solution: according to parts by weight, first put 1000 parts of deionized water in the reaction kettle, add bis(triethanolamine) diisopropyl titanate, stir rapidly, and the stirring speed is 150 rpm / min, stirring for 10 minutes, then adding CrO 3 , Mn 2 o 7 , stirr...

Embodiment 2

[0083] A method for preparing an ultra-high molecular weight polyethylene fiber reinforced material, comprising dipping in three baths, using the first bath dipping solution, the second bath dipping solution and the third bath dipping solution for dipping treatment respectively;

[0084] The total mass concentration of the first bath dipping is 5.5%, and the pH value is 5;

[0085] The total mass concentration of the second bath dipping is 20%, and the pH value is 9.5;

[0086] The total mass concentration of the dipping in the third bath is 18%, and the pH value is 9.0.

[0087] First bath dipping comprises following mass parts raw material:

[0088]

[0089] The preparation method of the first bath dipping liquid: first put 1000 parts of deionized water in the reaction kettle, add bis(triethanolamine) diisopropyl titanate, stir rapidly, the stirring speed is 150 rpm, stir 10 minutes, followed by the addition of CrO 3 , Mn 2 o 7 , stirring continuously for 1 hour. Th...

Embodiment 3

[0107] A method for preparing an ultra-high molecular weight polyethylene fiber reinforced material, comprising dipping in three baths, using the first bath dipping solution, the second bath dipping solution and the third bath dipping solution for dipping treatment respectively;

[0108] The total mass concentration of the first bath dipping is 3%, and the pH value is 4;

[0109] The total mass concentration of the dipping glue in the second bath is 16%, and the pH value is 8.5;

[0110] The total mass concentration of the dipping in the third bath is 14%, and the pH value is 8.5.

[0111] First bath dipping comprises following mass parts raw material:

[0112]

[0113] The preparation method of the first bath dipping liquid: first put 1000 parts of deionized water in the reaction kettle, add bis(triethanolamine) diisopropyl titanate, stir rapidly, the stirring speed is 150 rpm, stir 10 minutes, followed by the addition of CrO 3 , Mn 2 o 7 , stirring continuously for 1...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com