Anti-aging flame-retardant polylactic acid material and preparation method thereof

A polylactic acid material and anti-aging technology, applied in the field of degradable polymer materials, can solve the problems of limited application fields, easy aging and degradation, etc., and achieve the effect of strong combustion-to-charcoal ability and good absorption effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

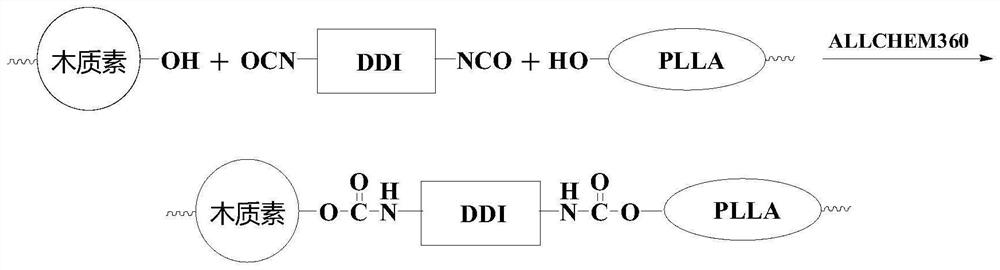

Method used

Image

Examples

Embodiment 1

[0029] 10 napper lignin, 1 part of stearic acid and 8 parts of polyphosphate were high-speed ball milling in the ball mill, resulting in a mixture of D50 of 8.1 microns; 40 parts of PLLA, pulverized mixture, 2 part antioxidants, DDI (DDI) 15% of acid lignin) and AllChem 360 (0.6% DDI) were mixed in a high mixing machine to obtain precursor 1. The precursor was extruded by a twin-screw extruder, granulated anti-aging flame retardant PLA material mother particles; mixing the mother particles with 60 parts of PLLA and 5 parts of PBS in a high mixing machine to obtain a precursor 2, and the precursor is used to melt co-extruder, granulation Old flame retardant PLLA material. Two-screw extruder (masterbatch preparation) one district 130 ° C, two districts 150 ° C, three regions 170 ° C, four regions 180 ° C, five districts 190 ° C, six districts 190 ° C, machine head 190 ° C, screw speed 150 rpm. Two-screw extruder (anti-aging flame retardant PLLA material production) 120 ° C, two dist...

Embodiment 2

[0031] 15 pieces of acidic lignin, 2 parts of stearic acid and 5 parts of polyphosphate were high-speed ball milling in the ball mill, resulting in a mixture of D50 of 1.8 microns; 50 parts of PLLA, a pulverized mixture, 1 part antioxidant, DDI ( 10% of acid lignin) and AllChem 360 (1% of DDI) were mixed in a high mixing machine to obtain a precursor, and the precursor was extruded by a twin-screw extruder, granulated anti-aging flame retardant PLA material mother particles; mixing the masterbatch with 50 parts of PLLA and 8 parts of PBS in a high mixing machine to obtain a precursor 2, and the precursor is used to melt co-extrusion, granulation Old flame retardant PLLA material. Twin screw extruder (masterbatch preparation) one district 130 ° C, two districts 150 ° C, three regions 170 ° C, four districts 180 ° C, five districts 190 ° C, six districts 195 ° C, head 195 ° C, screw speed 120 rpm. Twin screw extruder (anti-aging flame retardant PLLA material) 120 ° C, two districts ...

Embodiment 3

[0033] 2 parts of acidic lignin, 2 parts of stearic acid and 10 parts of polyphosphate were high-speed ball milling in the ball mill, resulting in a mixture of D50 of 14.3 microns; 30 parts of PLLA, pulverized mixture, 1.5 parts of antioxidants, DDI ( 20% of acid lignin) and AllChem 360 (1% of DDI) were mixed in a high mixing machine to obtain precursor, and the precursor was extruded by a twin-screw extruder, granulated anti-aging flame retardant PLA material mother particles; mixing the masterbatch with 70 parts of PLLA and 2 parts of PBS in a high mixing machine to obtain a precursor 2, and the precursor is used to melt co-extruder, granulated a kind of resistance Old flame retardant PLLA material. Twin screw extruder (masterbatch preparation) 125 ° C, two districts 145 ° C, three districts 165 ° C, four districts 175 ° C, five districts 185 ° C, six regions 185 ° C, head 185 ° C, screw rotation speed 200 rpm. Two-screw extruder (anti-aging flame retardant PLLA material prepara...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap