Concrete surface anti-carbonization curing agent, preparation method and application thereof

A technology for concrete surface and curing agent, applied in the direction of climate sustainability, sustainable waste treatment, solid waste management, etc. Economic benefits and market value, high production efficiency, simple production process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

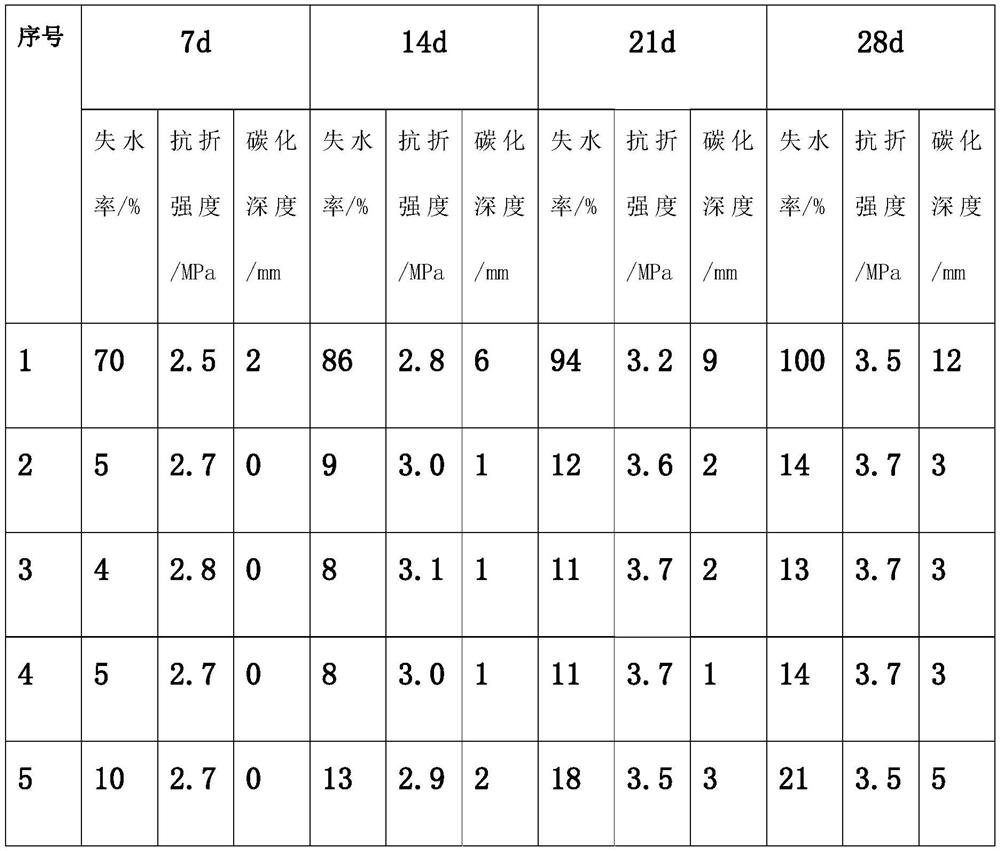

Embodiment 1

[0032] The present embodiment provides a kind of concrete maintenance agent, and its raw material comprises: α-methacrylic acid 150kg, sodium thiocyanate 190kg, acrylic acid emulsion 90kg, dodecyl alcohol ester 4kg, nano silicon dioxide 170kg, nano montmorillonite powder 45kg, Hydroxypropyl methylcellulose 3kg, industrial ethanol 1kg, water 195kg.

[0033] Wherein, the particle diameter of the nano silicon dioxide is 10nm, and the particle diameter of the nano montmorillonite powder is 10nm.

Embodiment 2

[0035]The present embodiment provides a kind of concrete maintenance agent, and its raw material comprises: α-methacrylic acid 230kg, sodium thiocyanate 240kg, acrylic acid emulsion 70kg, dodecyl alcohol ester 2kg, nano silicon dioxide 170kg, nano montmorillonite powder 35kg, Hydroxypropyl methylcellulose 1kg, industrial ethanol 1kg, water 206kg.

[0036] Wherein, the particle diameter of the nano silicon dioxide is 30nm, and the particle diameter of the nano montmorillonite powder is 30nm.

Embodiment 3

[0038] The present embodiment provides a kind of concrete maintenance agent, and its raw material comprises: α-methacrylic acid 200kg, sodium thiocyanate 220kg, acrylic acid latex 80kg, dodecyl alcohol ester 3kg, nano silicon dioxide 190kg, nano montmorillonite powder 35kg, Hydroxypropyl methylcellulose 1kg, industrial ethanol 3kg, water 195kg.

[0039] Wherein, the particle diameter of the nano-silica is 20nm, and the particle diameter of the nano-montmorillonite powder is 20nm.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com