Micro-ring optical switch based on three-dimensional integration of silicon-silicon nitride

A silicon nitride microring and three-dimensional integration technology, applied in the field of optical switches, can solve the problems of not fully utilizing the optical switch design scheme, immature implementation scheme, and failure to reflect advantages, etc., to achieve easy expansion, improve thermal tuning efficiency, The effect of simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] The following examples are further explained to the present invention. This instance is only used to explain the invention in detail, and it cannot be understood as a limit on the scope of protection of the present invention.

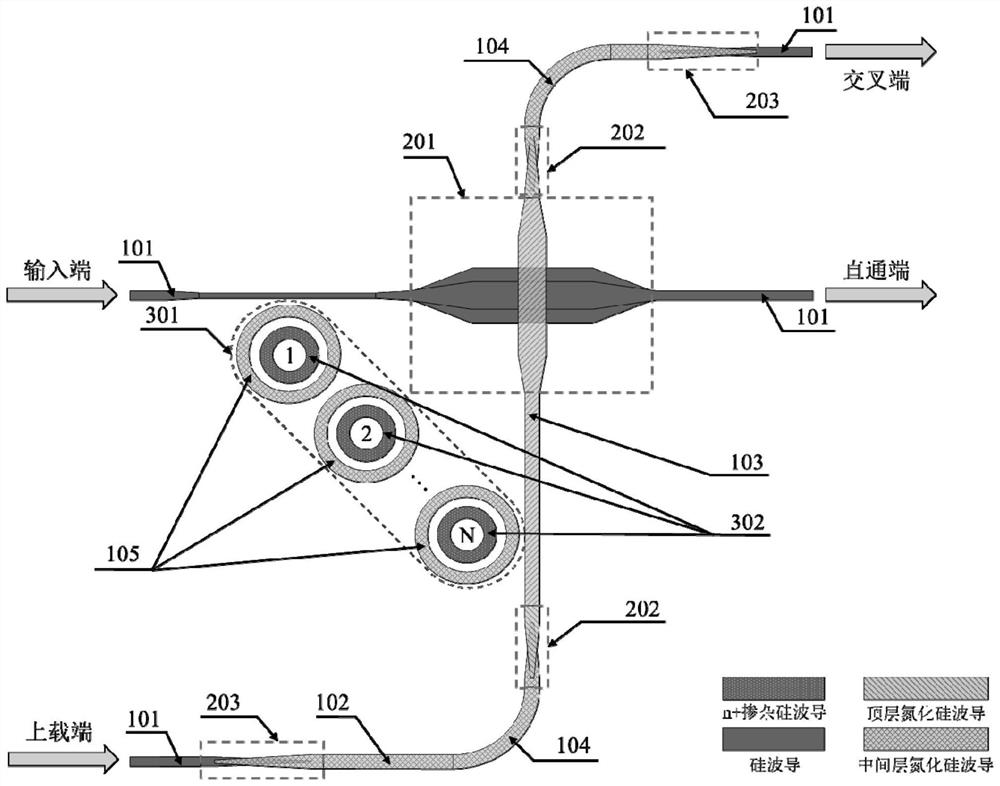

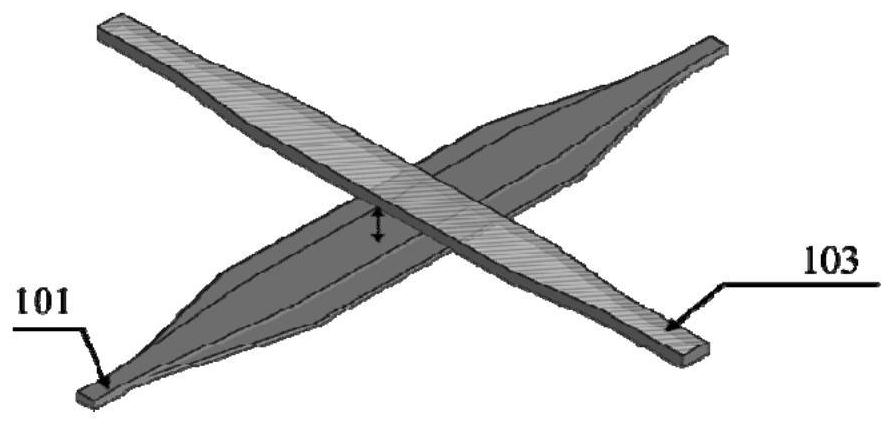

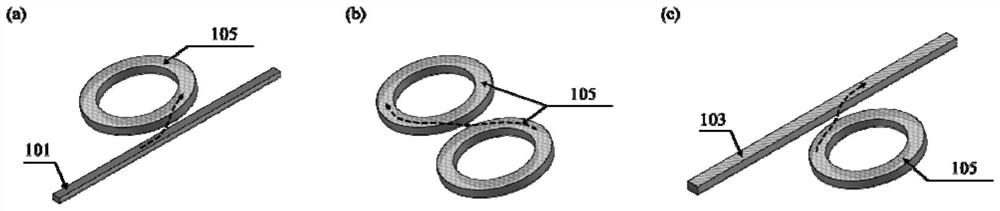

[0027] like figure 1 It shows that the present invention proposes a micro-circular switch based on silicon-silicon nitride-based three-dimensional integration. Two -layer silicon nitride waveguide (102, 103) is integrated on the silicon waveguide (101), and the silicon waveguide (101) is discharged horizontally by silicon waveguide (101) between the waveguide. The ranking, forming a three -dimensional wave interface (201); one end of the silicon waveguide (101) as the input end of the light signal, and the other end as the direct end; Polida (104), composed of silicon nitride microcirculation (105) with 360 ° bending; one end of the top layer of silicon nitride (103) through silicon nitrite-silicon nainer wave guide intercourse (202) and silicon nitr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com