Multi-layer fireproof environment-friendly cable

A multi-layer, environmentally friendly technology, applied in the direction of insulating cables, cables, circuits, etc., can solve the problems of no general improvement in the internal structure, lack of fire prevention technical effects, and unsatisfactory effects, etc., to achieve good fire protection and environmental protection performance , Excellent fire performance, good melting point

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] The present invention will be further illustrated below in conjunction with the accompanying drawings and specific embodiments. This embodiment is implemented on the premise of the technical solution of the present invention. It should be understood that these embodiments are only used to illustrate the present invention and are not intended to limit the scope of the present invention.

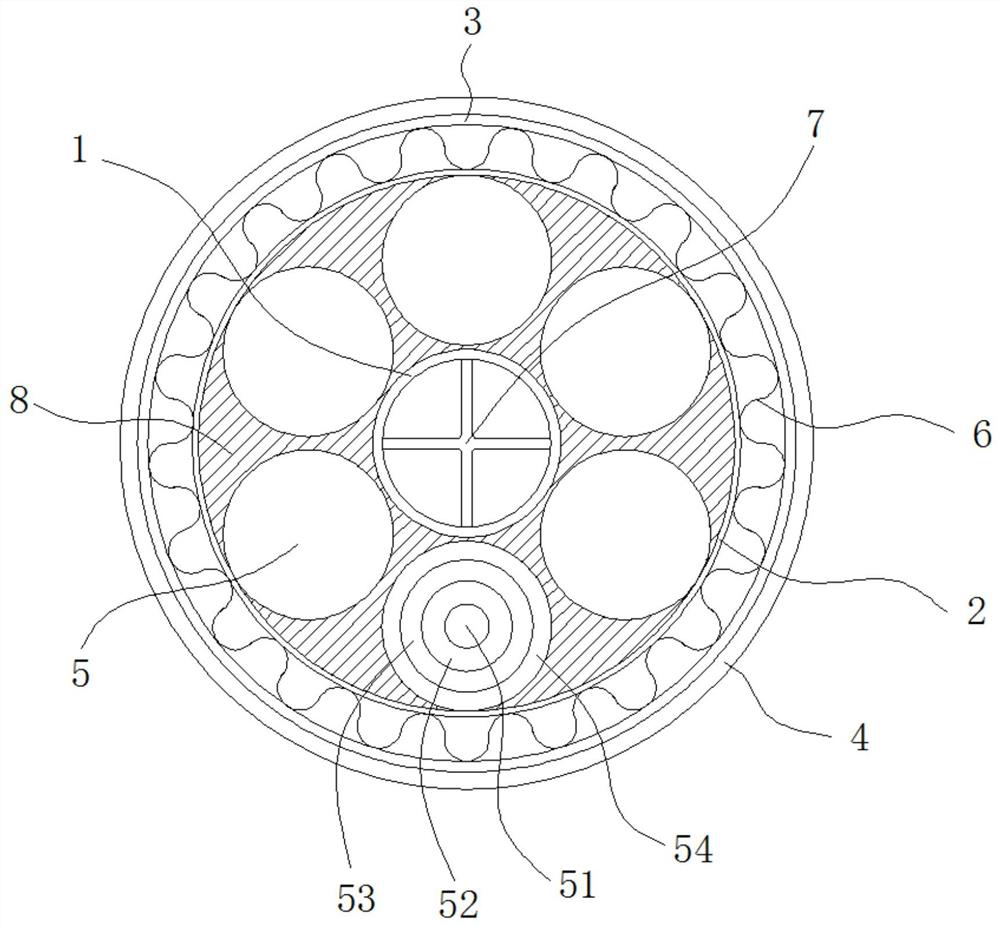

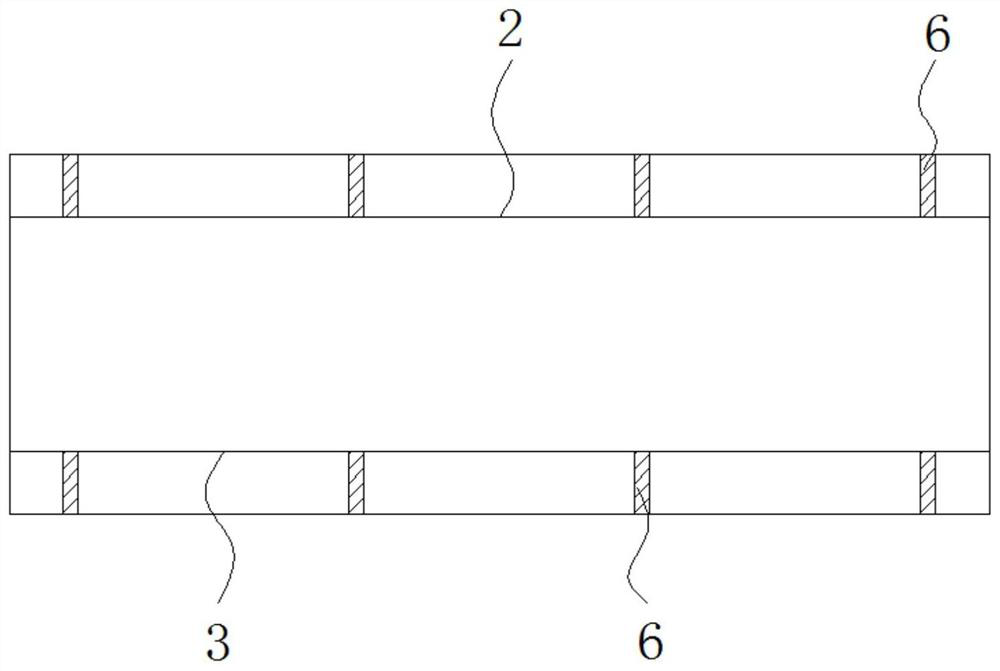

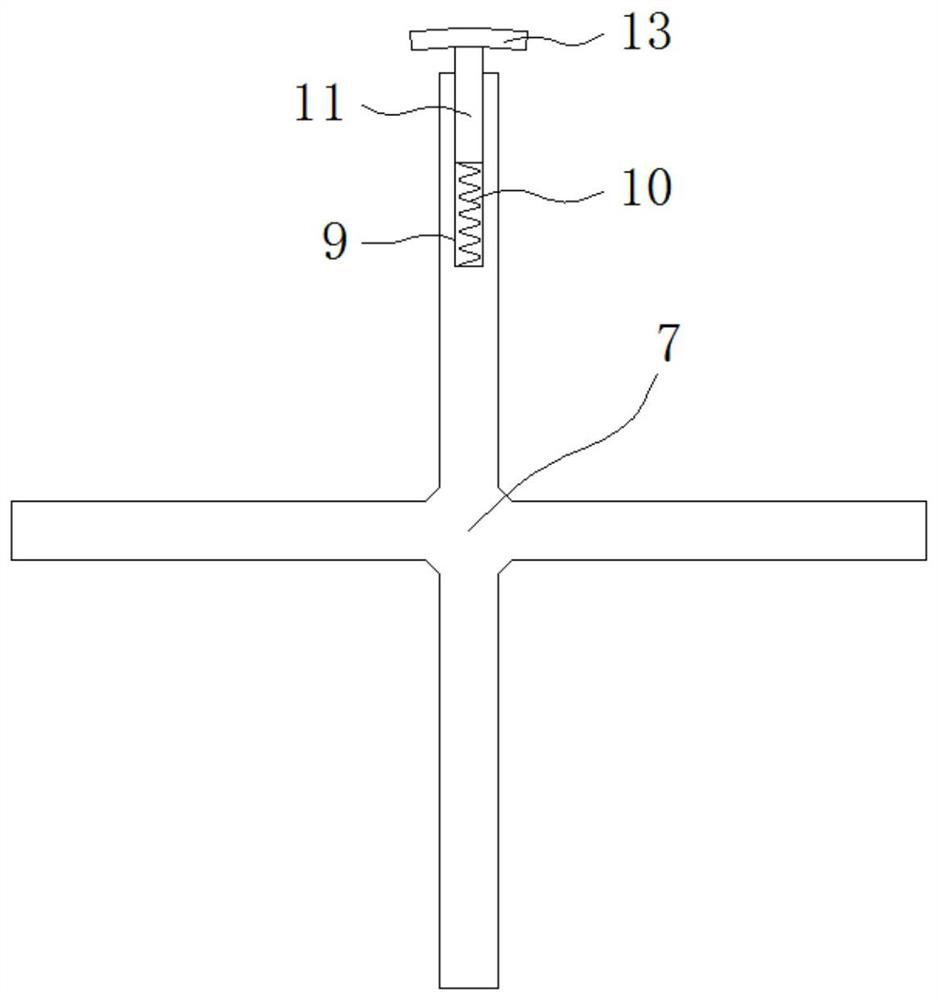

[0026] Such as figure 1 and figure 2 As shown, a multi-layer fireproof and environmental protection cable includes a central copper tube 1 arranged on the innermost layer, an inner copper tube 2 arranged outside the central copper tube 1, an outer copper tube 3 arranged outside the inner copper tube 2 and Closely attached to the fireproof and environmental protection outer sheath 4 outside the outer copper tube 3; the central copper tube 1, the inner copper tube 2 and the outer copper tube 3 are concentrically arranged; the inside of the central copper tube 1 is filled with a cooling l...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com