Cobalt-free lithium-rich positive electrode material as well as preparation method and application thereof

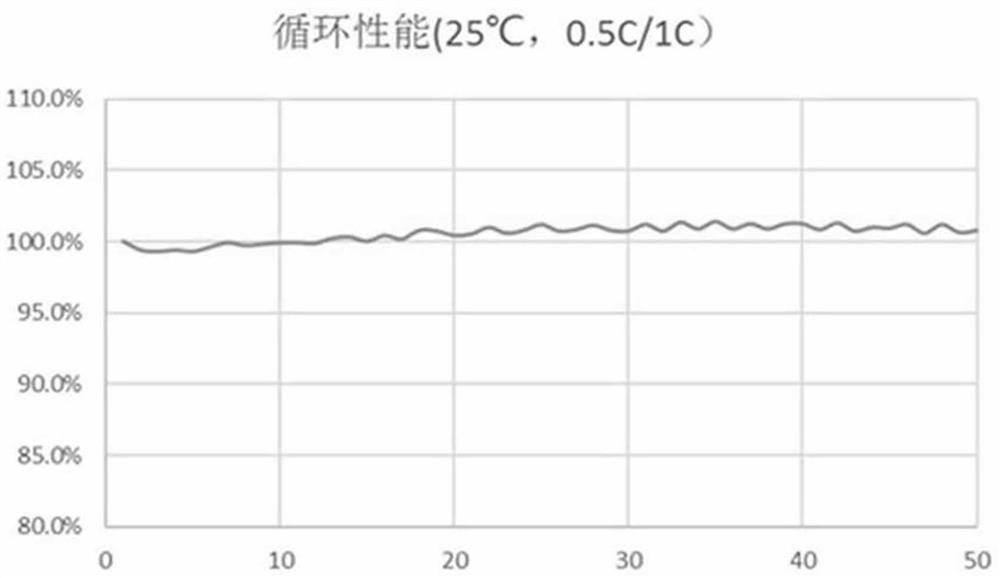

A lithium-rich cathode material, lithium source technology, applied in the direction of positive electrodes, chemical instruments and methods, inorganic chemistry, etc., can solve the problems of low capacity and troublesome preparation, and achieve the effect of improving cycle performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0052] This embodiment provides a cobalt-free lithium-rich positive electrode material whose chemical formula is , the positive electrode material through Ni 0.35 mn 0.65 (OH) 2 It is obtained by sintering after compounding with lithium carbonate, wherein the doping amount of Ti is 2000ppm, the coating amount of Zr is 2000ppm, and the coating amount of Al is 1500ppm;

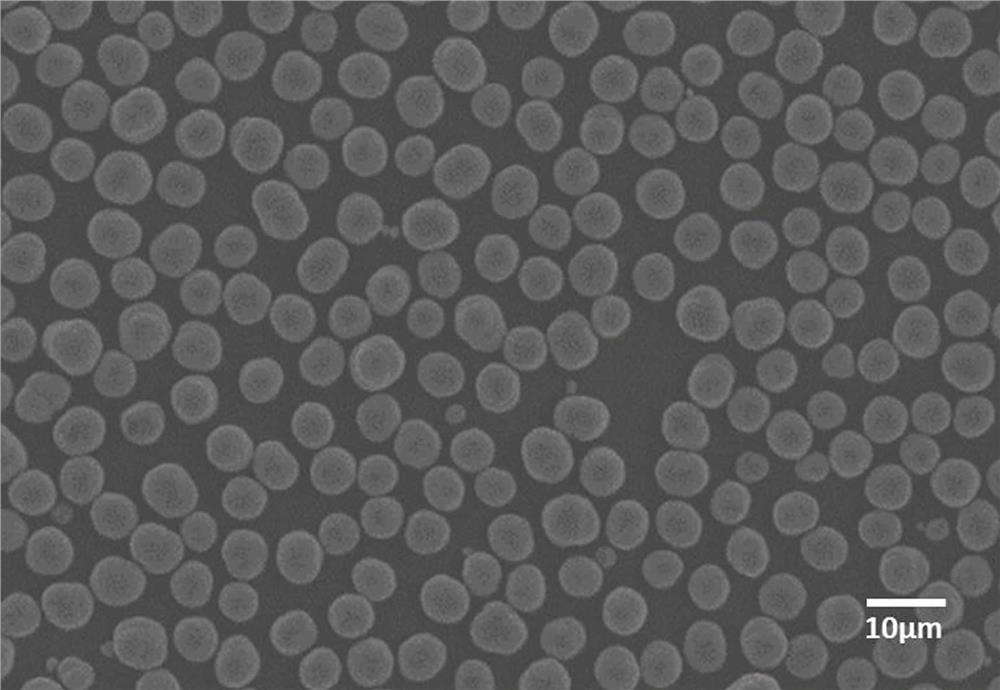

[0053] Ni 0.35 mn 0.65 (OH) 2 The specific surface area a is 25m 2 / g, the tap density b is 1.55g / cm 3 , which looks like figure 1 The spherical particles shown are spherical particles obtained from flake-like primary particles, with a median particle size of 5.5 μm;

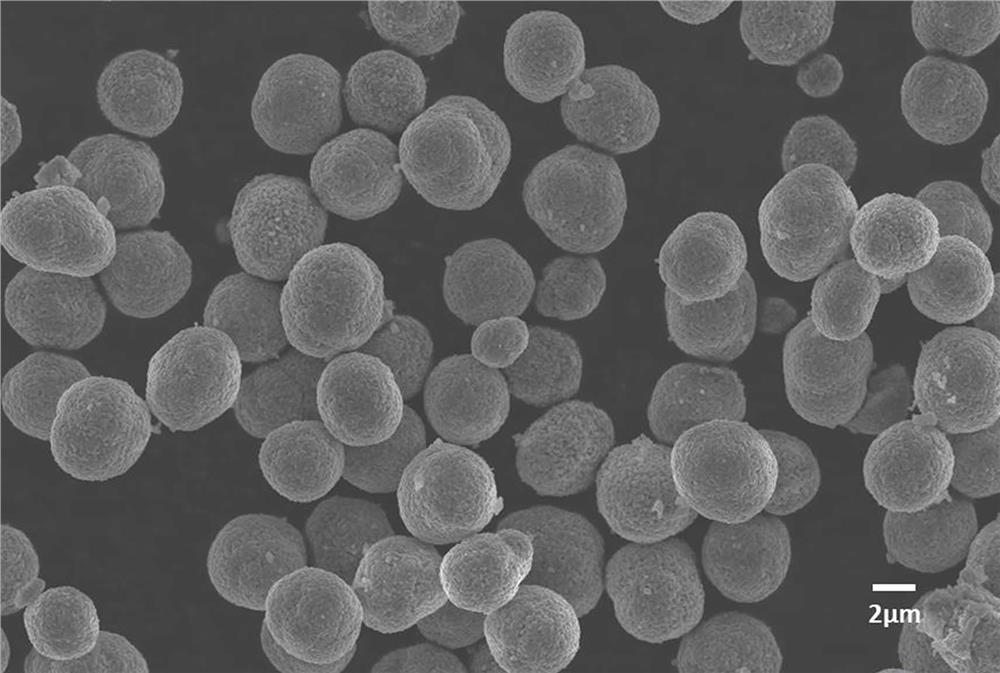

[0054] The specific surface area c of the cobalt-free lithium-rich cathode material is 1.5m 2 / g, the tap density d is 1.7g / cm 3 , which looks like figure 2 The spherical structure shown has a median particle size of 5.5 μm;

[0055] a / c+b / d=17.6.

[0056] The preparation method of the cobalt-free lithium-rich cathode material is as...

Embodiment 2

[0061] This embodiment provides a cobalt-free lithium-rich positive electrode material whose chemical formula is , the positive electrode material through Ni 0.25 mn 0.75 (OH) 2 It is obtained by sintering after compounding with lithium carbonate, wherein the doping amount of Al is 1500ppm, the coating amount of Zr is 2000ppm, and the coating amount of Ti is 2000ppm;

[0062] Ni 0.25 mn 0.75(OH) 2 The specific surface area a is 20m 2 / g, the tap density b is 1.5g / cm 3 ;

[0063] The specific surface area c of the cobalt-free lithium-rich cathode material is 5.0m 2 / g, the tap density d is 1.5g / cm 3 ;

[0064] a / c+b / d=5.

[0065] The preparation method of the cobalt-free lithium-rich cathode material is as follows:

[0066] (1) NiSO 4 ·6H 2 O, MnSO 4 ·H 2 O is formulated into a 2mol / L aqueous solution according to the stoichiometric ratio, NaOH aqueous solution is used as a precipitating agent with a concentration of 4mol / L, and NH 3 ·H 2 O is used as a compl...

Embodiment 3

[0069] This embodiment provides a cobalt-free lithium-rich positive electrode material whose chemical formula is , the positive electrode material through Ni 0.30 mn 0.70 (OH) 2 It is obtained by sintering after compounding with lithium carbonate, wherein the doping amount of Nb is 2500ppm, the coating amount of Mg is 1000ppm, and the coating amount of Ti is 2500ppm;

[0070] Ni 0.30 mn 0.70 (OH) 2 The specific surface area a is 26m 2 / g, the tap density b is 1.4g / cm 3 ;

[0071] The specific surface area c of the cobalt-free lithium-rich cathode material is 1.1m 2 / g, the tap density d is 1.0g / cm 3 ;

[0072] a / c+b / d=25.

[0073] The preparation method of the cobalt-free lithium-rich cathode material is as follows:

[0074] (1) NiSO 4 ·6H 2 O, MnSO 4 ·H 2 O is formulated into a 4mol / L aqueous solution according to the stoichiometric ratio, NaOH aqueous solution is used as a precipitating agent, the concentration is 8mol / L, and NH 3 ·H 2 O is used as a compl...

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com