Ultrafast laser cutting method for miniature oil filter screen of engine

An ultra-fast laser and cutting method technology, applied in the direction of laser welding equipment, welding/cutting auxiliary equipment, auxiliary devices, etc., can solve the problems of low production efficiency and poor quality stability of microholes, and achieve high production efficiency and high cutting efficiency , the effect of improving production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

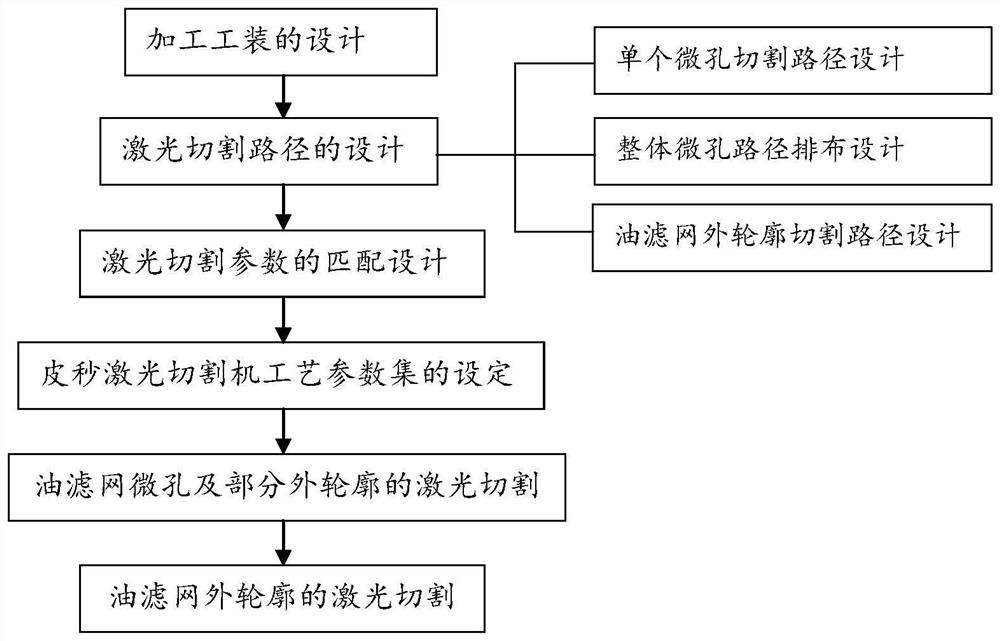

[0059] In this embodiment, the miniature oil strainer is a circular pure titanium product with a thickness of 0.1mm. Figure 1-Figure 6D , the specific cutting process is as follows:

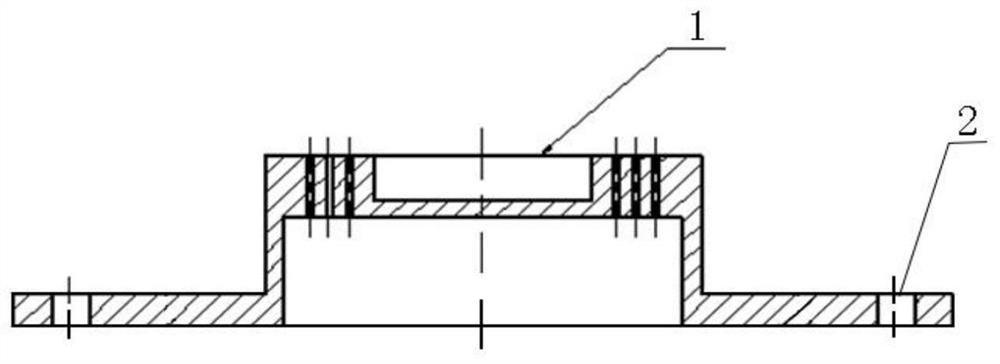

[0060] Step (1), design a processing tool according to the outer contour and size of the miniature oil filter screen (such as Figure 3A and Figure 3B shown), the processing tooling includes a raw material placement table 1 and a flange 2 fixedly connected to the raw material placement table 1, and the flange 2 connects the processing tooling to the working table of the picosecond laser cutting machine through bolts. Among them, the key to the processing tooling The original design is the raw material placement table 1. The raw material placement table 1 can ensure the parallelism between the raw material of the oil filter screen and the machine tool processing platform under the action of vacuum ejection. Design, wherein, evenly distributed circular holes are located on the raw material plac...

Embodiment 2

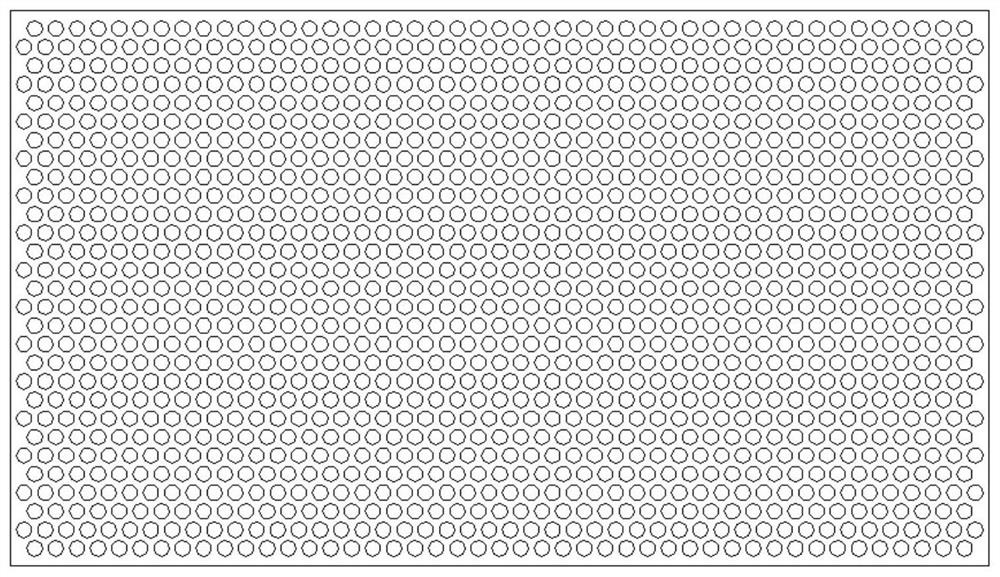

[0080] In the present embodiment, the miniature oil strainer is a square stainless steel product (such as figure 2 shown), the thickness is 0.3mm, the specific cutting process is as follows:

[0081] Step (1), design a processing tool according to the outer contour and size of the micro-oil filter, the design method of the processing tool is the same as step (1) in Example 1, wherein the diameter of the uniformly distributed circular holes ranges from Φ1. 0mm~Φ1.2mm, the round hole avoids a single groove, is located on the raw material placement platform 1, and is distributed in a symmetrical pattern around the groove; the shape of the single groove in this embodiment is square, and the depth range is 7mm to 10mm; The size of the single groove is larger than the size of the oil filter screen to be processed, and the lengths of the four sides are all increased by 0.5 mm to 1.5 mm on the basis of the length of one side of the oil filter screen to be processed.

[0082] Step (2...

PUM

| Property | Measurement | Unit |

|---|---|---|

| depth | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com