Preparation method of leaf-based nitrogen-doped porous carbon, and application of leaf-based nitrogen-doped porous carbon in oxygen reduction electro-catalysis within full pH range

A nitrogen-doped, porous carbon technology, applied in chemical instruments and methods, circuits, inorganic chemistry, etc., can solve problems that hinder the development and commercialization of fuel cell technology, lack of precious metal reserves, poisoning and deactivation, etc., to promote commercial The chemical process, the experimental scheme is simple and feasible, and the effect of promoting mass transfer

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

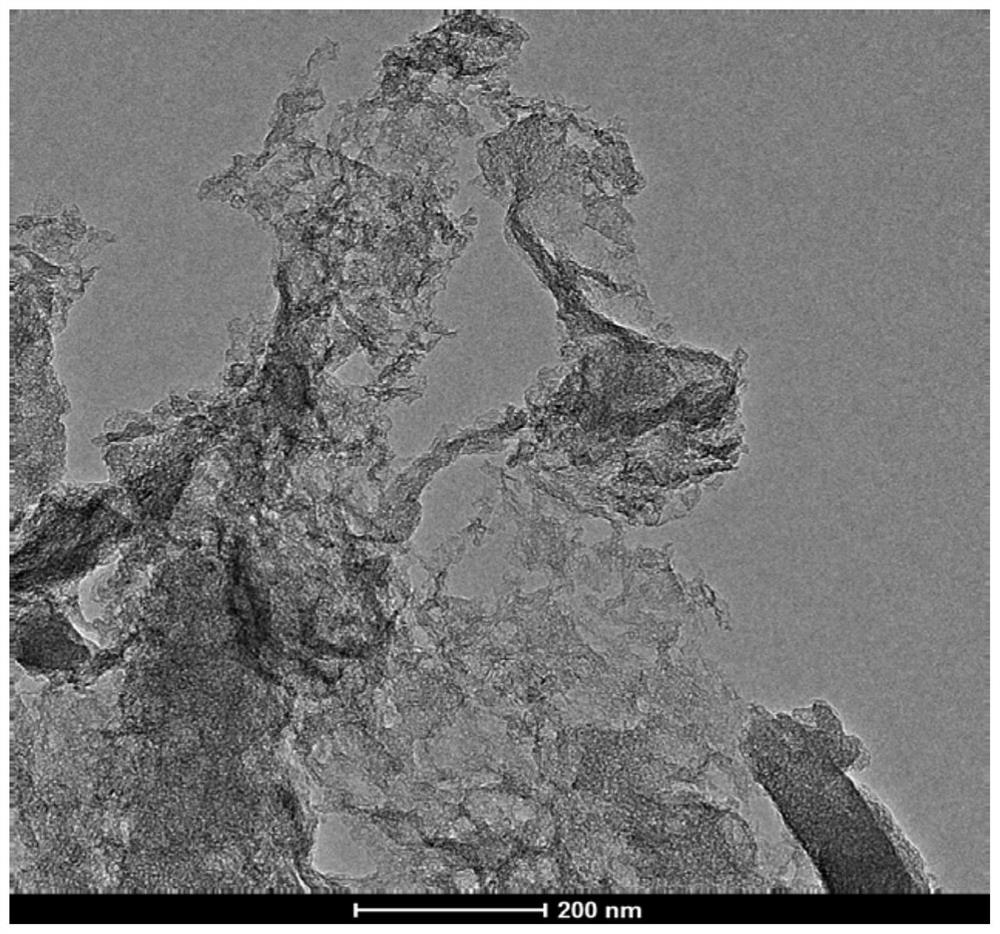

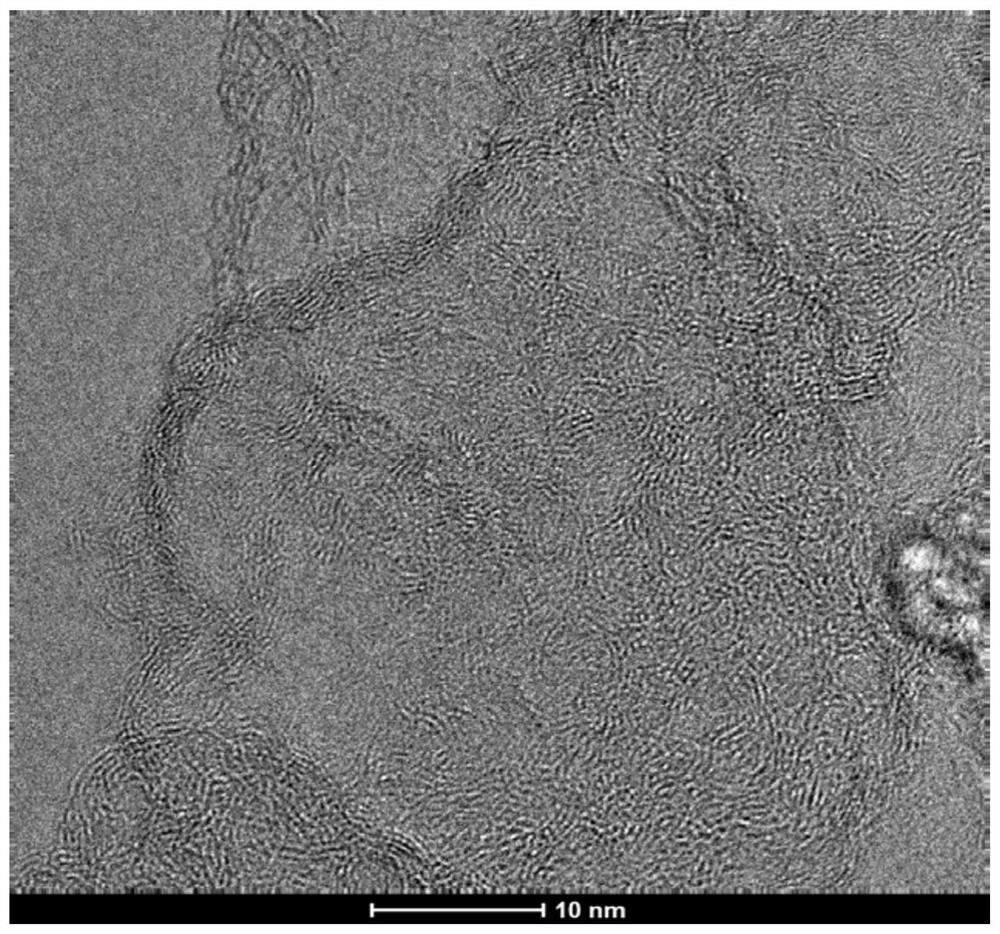

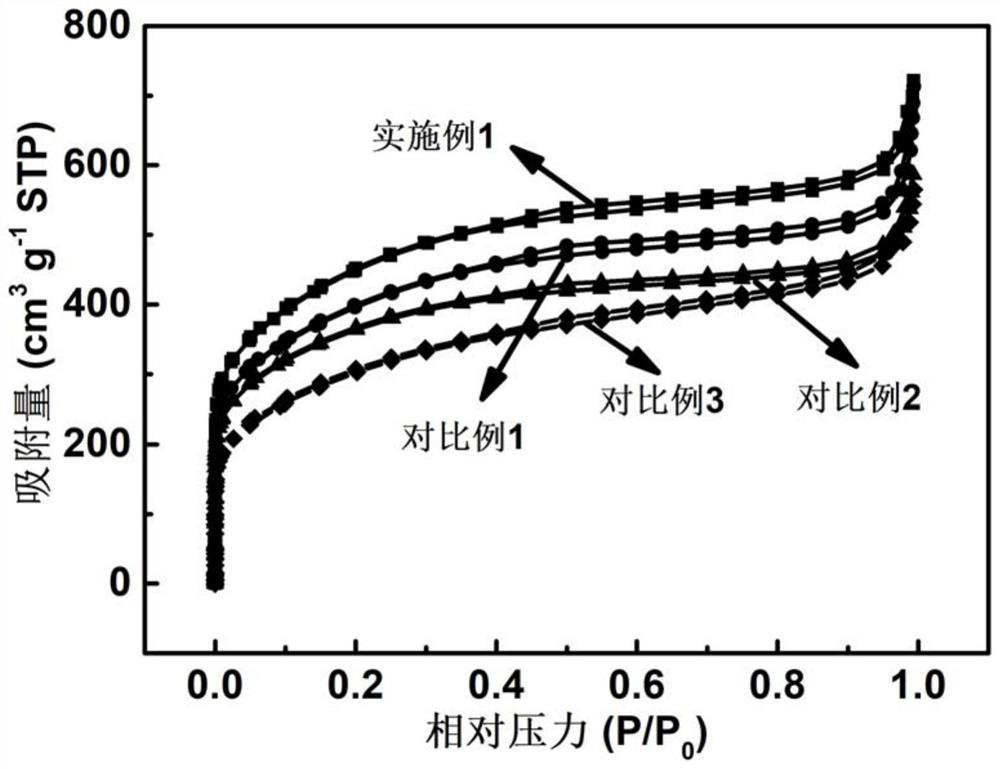

[0045] The collected cypress leaves were fully washed with deionized water, dried at 80°C, and slightly ground with a mortar. Weigh 3.0 g of treated cypress leaves, soak them in an acetic acid-sodium acetate buffer solution (pH=4.8) containing hemicellulase (enzyme activity 200 U / g), and then place them in a constant temperature water bath at 50°C After 24 hours of incubation, after the enzymatic hydrolysis was completed, the samples were filtered and washed with water until neutral, and then dried at 80°C. Dry the sample in N 2 Under the atmosphere, the temperature was raised to 400°C at a rate of 5°C / min, carbonized for 2 hours, then cooled to 300°C at a rate of 5°C / min, and then cooled to room temperature to obtain biochar. Grind the pre-carbonized biochar with an agate mortar for 10 min to form a powder, and pack it into a bag for later use.

[0046] Weigh 0.5g of biochar, 1.5g of melamine, 0.5g of potassium hydroxide and 1.5g of potassium bicarbonate and place them in a...

PUM

| Property | Measurement | Unit |

|---|---|---|

| specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com