Preparation method of modified hexanitrohexaazaisowurtzitane, modified hexanitrohexaazaisowurtzitane and application of modified hexanitrohexaazaisowurtzitane

A technology of hexanitrohexanitrogen and isowurtzane, which is applied in the field of compound surface modification, can solve the problems of poor particle mechanical properties, limited inhibition degree, poor mechanical properties, etc., achieve uniform coating, increase coating thickness, shorten The effect of reaction time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

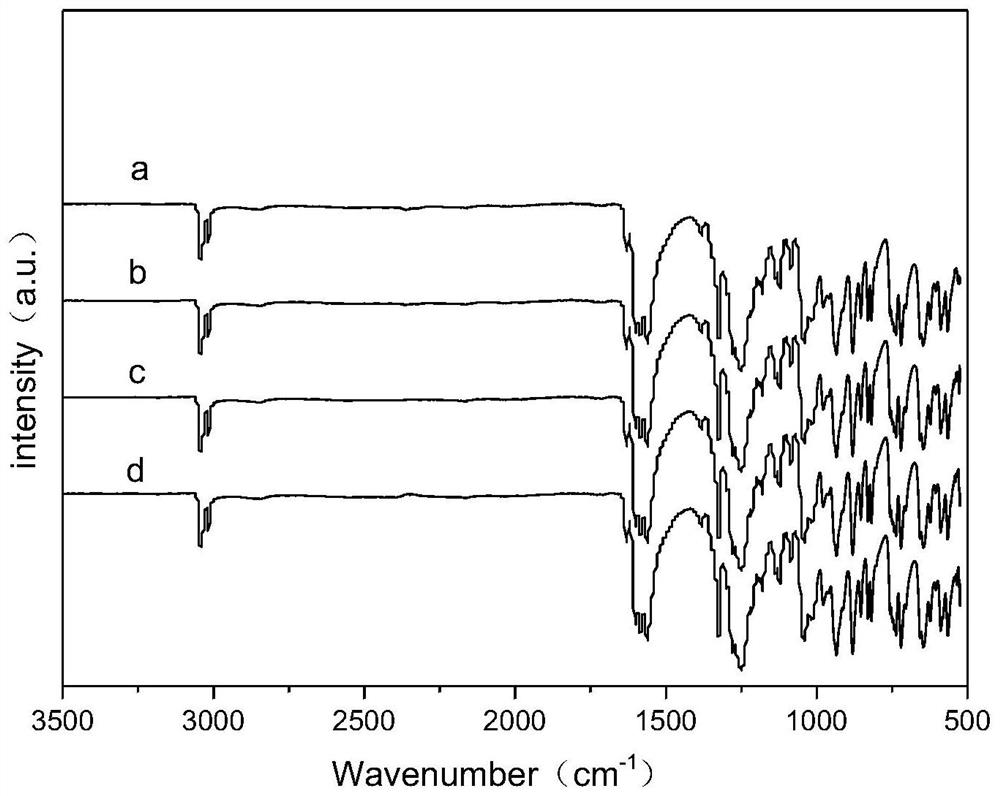

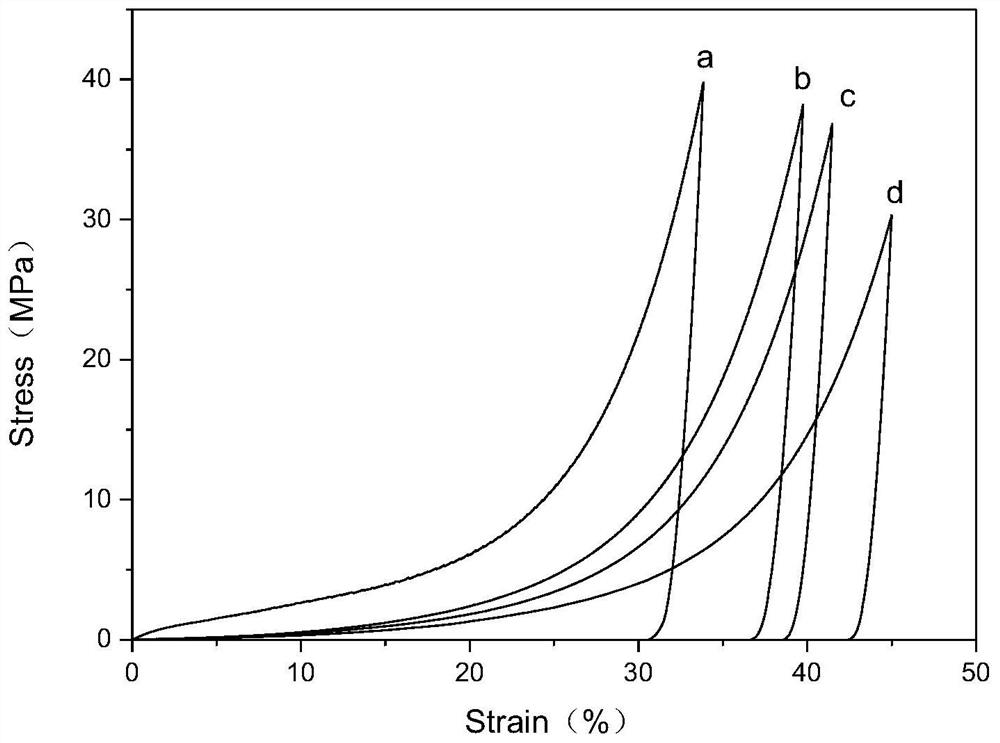

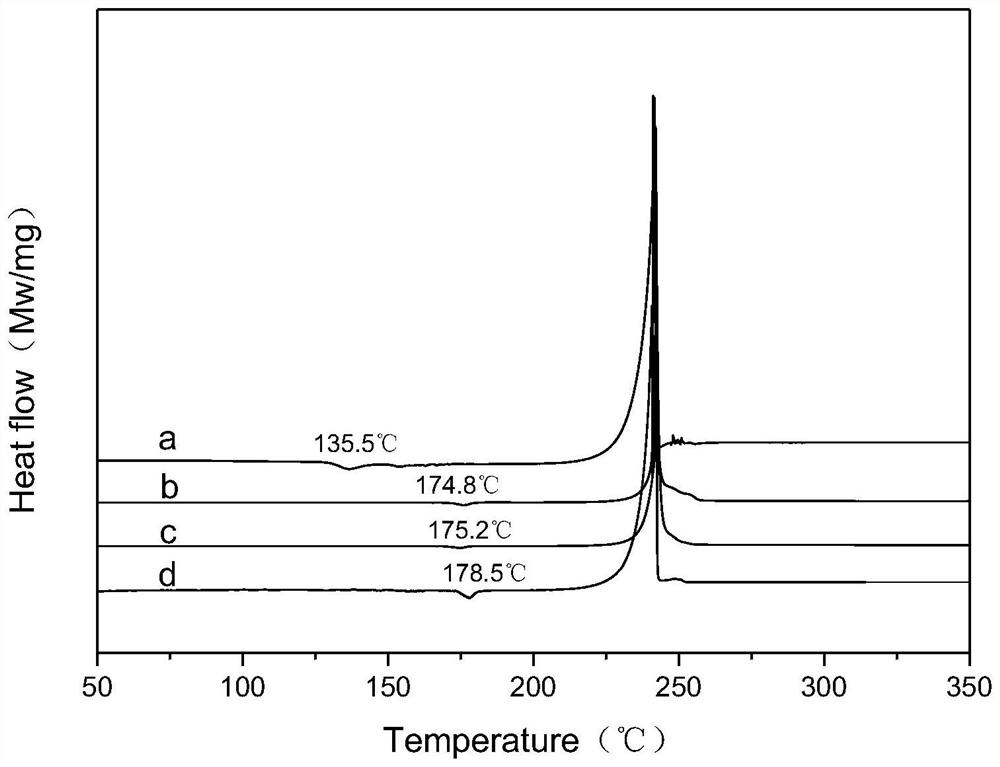

[0070] Weigh 5g of ε-CL-20 raw material with an average particle size of 150um and add it to 50ml of 0.1mol / L Tris-HCl buffer solution with a pH value of 8.5, and stir ultrasonically for 20min to disperse evenly to form a suspension.

[0071] Weigh 0.25 g of dopamine and add it to the above suspension, and continuously blow air into the solution at a rate of 3 L / min to accelerate the dissolution of dopamine hydrochloride to prepare a 5.0 g / L dopamine solution. Continuously blow in air at a rate of 3 L / min for 1 h at room temperature, wash with absolute ethanol for 3 times, and dry in a vacuum oven for 6 h at a drying temperature of 55°C to obtain polydopamine-coated modified ε-CL-20 .

[0072] The feeding ratio is 5%, and the coating ratio is 4.4%.

Embodiment 2

[0074] Weigh 5g of ε-CL-20 raw material with an average particle size of 150um and add it to 50ml of 0.1mol / L Tris-HCl buffer solution with a pH value of 8.5, and stir ultrasonically for 20min to disperse evenly to form a suspension.

[0075] Weigh 0.25g of levodopa and add it to the above-mentioned suspension, continuously blow air into the solution at a speed of 3L / min to accelerate the dissolution of levodopa, and prepare a 1.0g / L levodopa solution. At room temperature, the air was continuously blown in at a rate of 3 L / min for 1 hour. After suction filtration of the obtained product, the obtained solid was washed 3 times with absolute ethanol, and placed in a vacuum drying oven to dry for 6 hours at a drying temperature of 55°C to obtain poly-levodopa packets. Covered modified ε-CL-20.

[0076] The feeding ratio is 5%, and the coating ratio is 4.2%.

Embodiment 3

[0078] Weigh 5g of ε-CL-20 raw material with an average particle size of 150um and add it to 100ml of 0.5mol / L Tris-HCl buffer solution with a pH value of 8.8, and stir ultrasonically for 20min to disperse evenly to form a suspension.

[0079] Weigh 0.225g of 6-hydroxydopamine hydrochloride and add it to the above suspension, continuously blow air into the solution at a rate of 3L / min to accelerate the dissolution of 6-hydroxydopamine hydrochloride, and prepare 5.0g / L of 6-hydroxydopamine hydrochloride. Dopamine solution. Air was continuously blown in at a rate of 4 L / min for 2 hours at room temperature, washed 3 times with absolute ethanol, and dried in a vacuum oven for 4 hours at a drying temperature of 65°C to obtain poly-6-hydroxydopamine hydrochloride-coated modified ε-CL-20.

[0080] The feeding ratio is 5%, and the coating ratio is 4.2%.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com