Multi-effect synergistic flame-retardant polyol composition

A polyol composition and a technology for synergistic flame retardant, applied in the field of polyurethane synthesis, can solve the problem that flame retardants cannot achieve flame retardant effect, and achieve the effect of good compatibility and efficient synergy.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

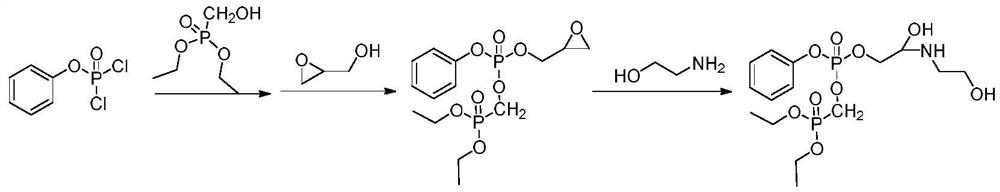

Method used

Image

Examples

preparation example Construction

[0023] The preparation process of the silicon-boron flame retardant is:

[0024] Grind the crude diatomite and disperse it in deionized water, add 3mol / L concentrated sulfuric acid, stir rapidly at 70-80°C for 1-2 hours, wash with water until neutral, dry, grind and sieve;

[0025] Disperse 10g of diatomite powder after treatment in deionized water, add 0.2g of AEO-3 after dispersing evenly, then add 0-10wt% boric acid solution, add while stirring, dehydrate and dry at 50-60°C, and then calcined to obtain Boron-containing diatomaceous earth powder.

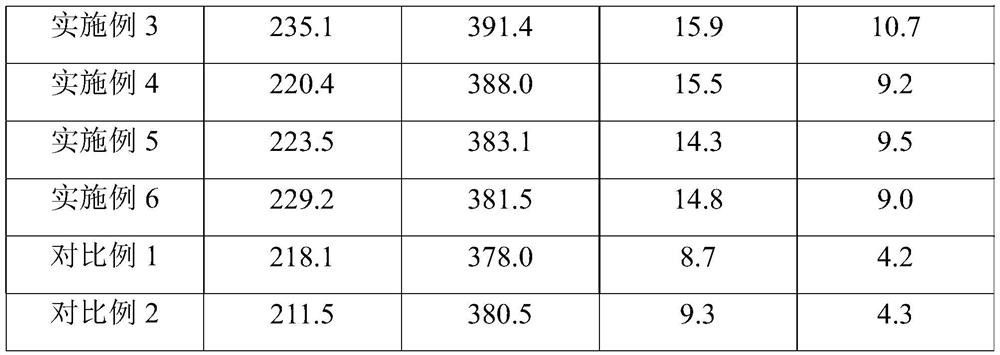

[0026] By changing the amount of boric acid solution and fluorine-containing polyether polyol solution, the following specific silicon-boron flame retardant samples can be obtained:

[0027] Silicon-boron flame retardants A→D respectively correspond to: 10wt% boric acid solution, 6wt% boric acid solution, 4wt% boric acid solution, 0wt% boric acid solution.

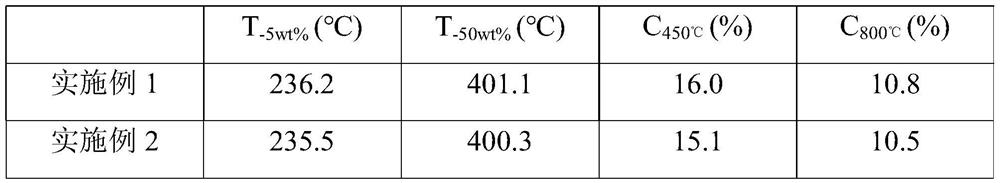

Embodiment 1

[0029] 35 wt% phosphorus-nitrogen polyol, 15 wt% silicon-boron flame retardant A, and 50 wt% polyethylene adipate butylene glycol ester diol.

Embodiment 2

[0031] 30 wt% phosphorus-nitrogen polyol, 10 wt% silicon-boron flame retardant A, and 60 wt% polybutylene adipate hexanediol diol.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com