Low-foam scouring agent for cotton woven fabric continuous pad dyeing and preparation method of low-foam scouring agent

A technology for woven fabrics and scouring agents, which is applied in the field of low-foaming scouring agents for long-vehicle cotton woven fabrics and its preparation. Good degreasing effect, strong emulsifying ability and good compatibility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

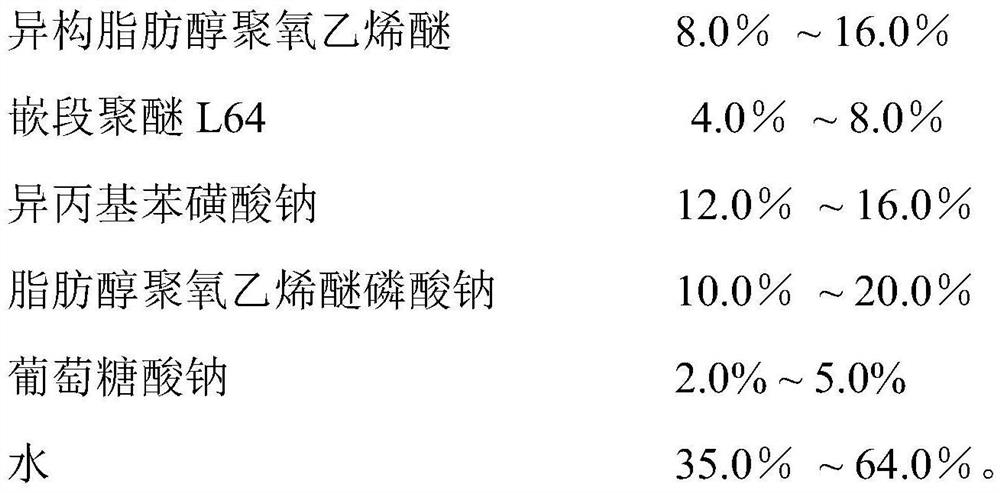

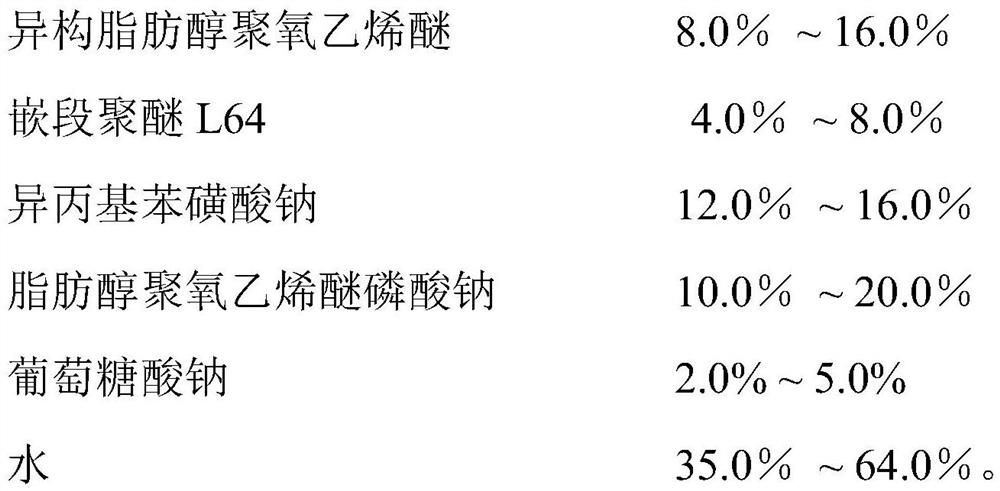

[0025] A low-foaming scouring agent for long cars, comprising the following components, each component is by weight percentage:

[0026]

[0027] The preparation method is as follows: Weigh the isomeric fatty alcohol polyoxyethylene ether, block polyether L64, and sodium cumene sulfonate in a clean reaction kettle in sequence according to the mass percentage, start the stirrer, and stir thoroughly for 30-50 minutes , then add fatty alcohol polyoxyethylene ether sodium phosphate and sodium gluconate, raise the temperature to 50-60°C, slowly add measured pure water (add it in about 30-60 minutes), and continue to heat up at 50-60°C After heat preservation and stirring for 1-2 hours, after fully stirring evenly, cool down to 30-40°C and filter out the material, which is the low-foaming scouring agent for long vehicles.

Embodiment 2

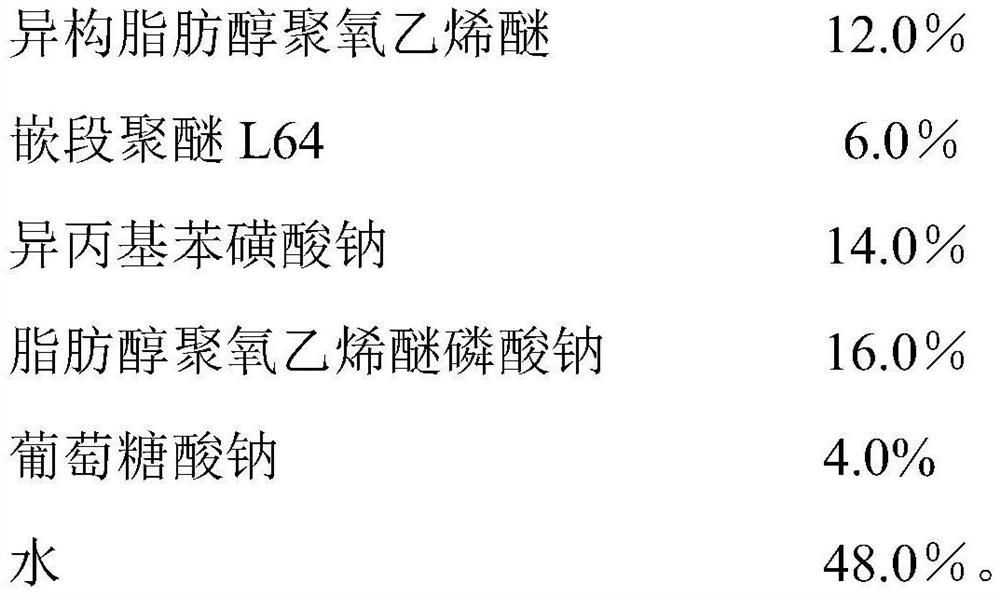

[0029] A low-foaming scouring agent for long cars, comprising the following components, each component is by weight percentage:

[0030]

[0031] The preparation method is as follows: Weigh the isomeric fatty alcohol polyoxyethylene ether, block polyether L64, and sodium cumene sulfonate in a clean reaction kettle in sequence according to the mass percentage, start the stirrer, and stir thoroughly for 30-50 minutes , then add sodium fatty alcohol polyoxyethylene ether carboxylate and sodium gluconate, raise the temperature to 50-60°C, slowly add measured pure water (completely add in about 30-60 minutes), and continue at 50-60°C After stirring under heat preservation for 1-2 hours, after fully stirring evenly, cool down to 30-40°C and filter out the material, which is the low-foaming scouring agent for long vehicles.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com