Partition plate type dust-falling, temperature-adjusting and pressure-stabilizing flue gas pretreatment device and application process

A pretreatment device and clapboard-type technology, applied in the direction of waste heat treatment, furnace control device, furnace, etc., can solve the problems of reducing the amount of desulfurization and denitrification hazardous waste, flue gas system pressure fluctuations, increasing the intermixing of cold air, etc., to achieve reduction The effect of desulfurization and denitrification hazardous waste, increasing system stability, and reducing the load of the main fan

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

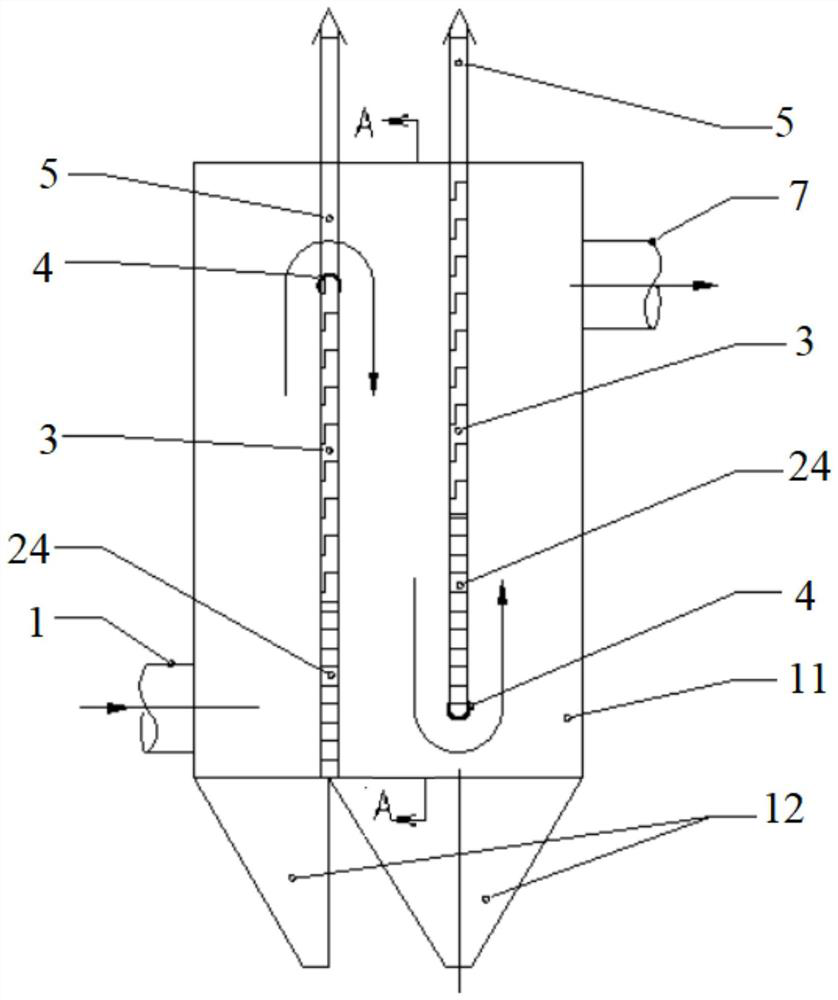

[0038] Such as figure 1 As shown, a clapboard-type dust-reducing, temperature-regulating, and pressure-stabilizing flue gas pretreatment device in this embodiment includes a dust-reducing, pressure-stabilizing, and temperature-regulating box body 11 and flue gas input pipes 1 that are fixedly connected with openings on both sides of the box walls. And the flue gas output pipe 7 also includes a particle dust collecting bucket 12 connected to the bottom of the dust-reducing and stabilizing temperature-regulating box 11; the vertically fixed connection of the dust-falling and stabilizing-pressure and temperature-regulating box 11 has the same height, alternately distributed up and down Two internal hollow self-flowing air heat exchange partitions 3, the upper end of the self-flowing air heat exchange partition 3 near and facing the flue gas input pipe 1 reserves a flue gas channel, and the self-flowing air near and facing the flue gas output pipe 7 The flue gas channel is reserve...

Embodiment 2

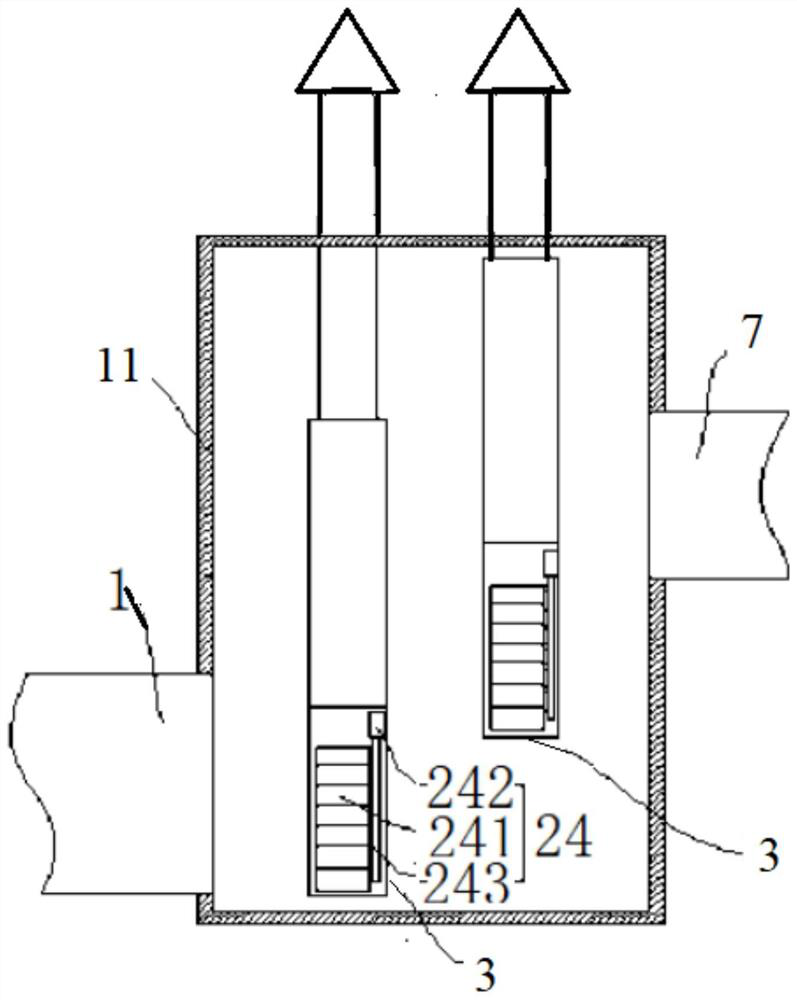

[0044] A clapboard-type dust-reducing, temperature-regulating, and pressure-stabilizing flue gas pretreatment device of this embodiment is basically the same as that of Embodiment 1. Furthermore, the self-flowing air heat exchange partitions 3 are equally spaced in the dust-reducing, pressure-stabilizing, and temperature-regulating box. Make the entire heat exchange process evenly hand over, avoid the violent exchange process, further avoid the strong disturbance of the cold wind to the flue gas, and stabilize the pressure of the flue gas transmission pipeline. Such as figure 2 As shown, the mouth of the air intake pipe 23 is equipped with an adjustable damper 24, which can adjust the size of the damper according to the temperature of the crude flue gas produced, thereby adjusting the amount of intermixed cold air. Damper 24 comprises louver 241 and electric push rod 242, and described louver 241 is evenly distributed a plurality of from top to bottom, and one end of louver 2...

Embodiment 3

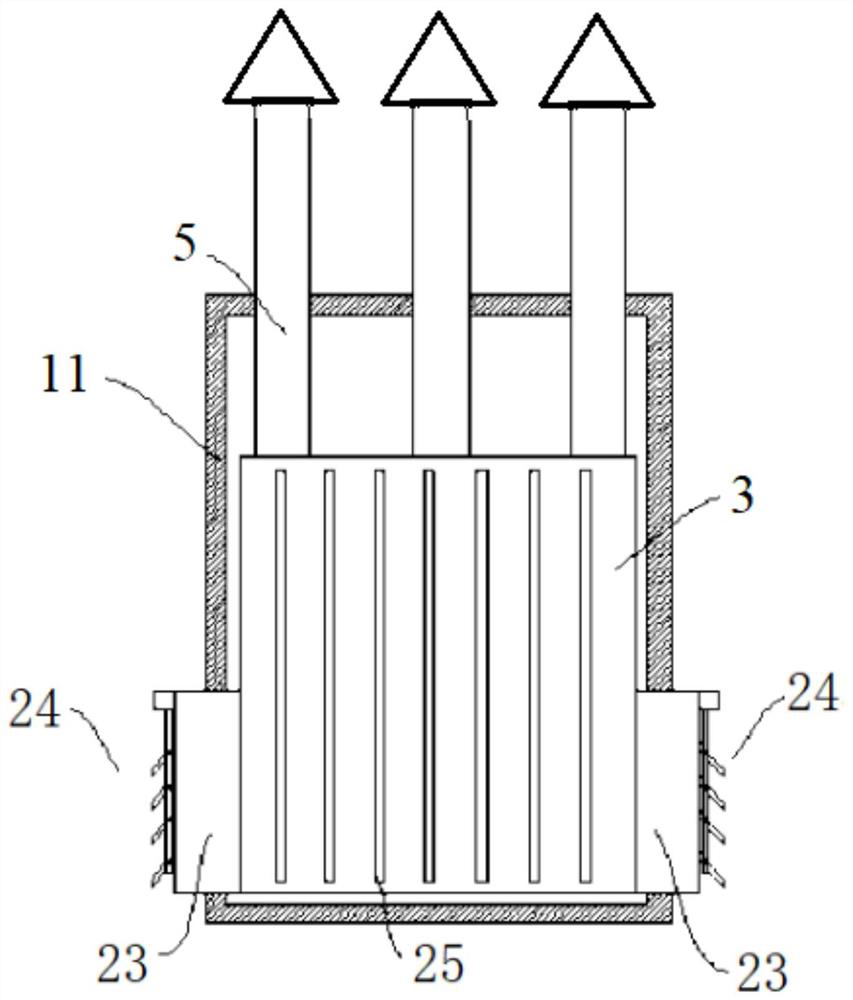

[0047] The basic structure of the clapboard-type dust-reducing, temperature-regulating, and pressure-stabilizing flue gas pretreatment device of this embodiment is the same as that of the above-mentioned embodiment, and further, as Figure 4 As shown, a "W"-shaped deflector 26 is connected between the front inner wall and the rear inner wall of the self-flowing air heat exchange partition 3, which can prevent the atmosphere from generating roundabout disturbances in the dust-reducing, pressure-stabilizing, and temperature-regulating box, and improve the atmosphere. At the same time, it plays the role of reinforcing ribs, which enhances the mechanical strength of the dust-reducing, pressure-stabilizing and temperature-regulating box. Such as image 3 As shown, the front outer wall and the rear outer wall of the self-flowing air heat exchange partition 3 are connected with heat exchange fins 25 to increase the heat exchange area for indirect blending of cold air in the productio...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com