Sulfated schizophyllan, preparation method thereof and application of sulfated schizophyllan in cosmetics

A technology of schizophyllan and sulfation, which is applied in the field of sulfation of schizophyllan and its preparation, can solve the problems of low solubility, low yield of carboxymethylated products, and low yield, and achieve enhanced moisturizing activity Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

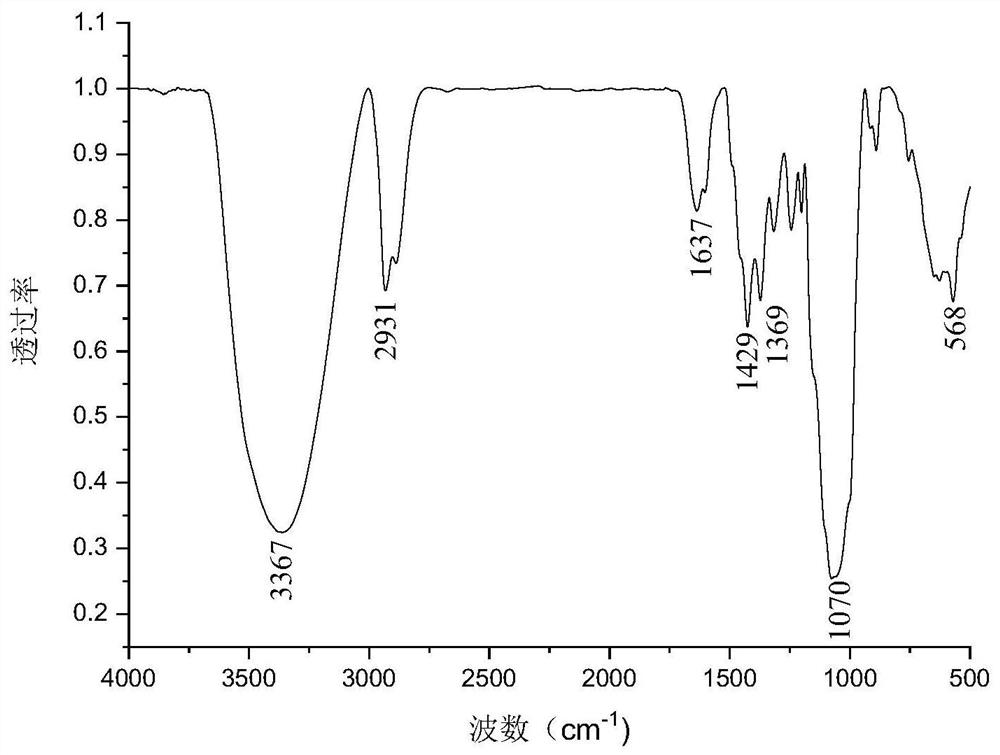

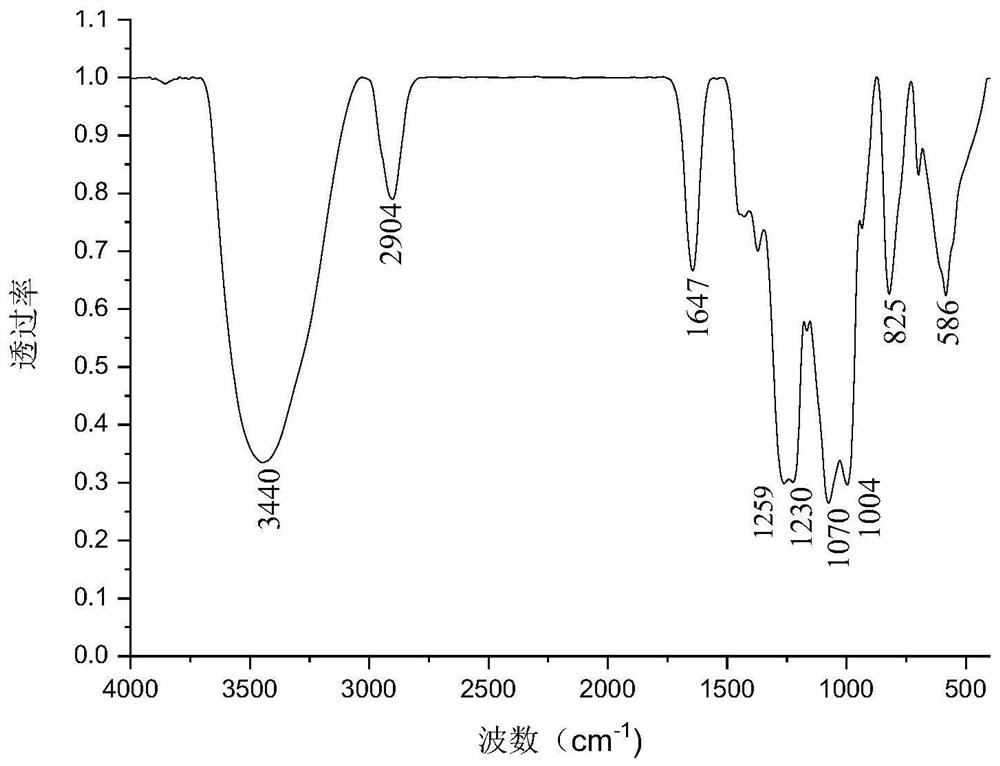

[0045] Take 2g of dried Schizophyllan, put it into a screw-necked Erlenmeyer flask, add 300mL of DMF, and infiltrate in a dry environment for 12h. Add 4 g of pyridine sulfur trioxide, react in a water bath at 70° C. for 2 h, and stir at 700 rpm. Then quickly lower the temperature to 20°C, add concentrated sulfuric acid with 1 times the mass of dry Schizophyllan, and continue the reaction for 10 minutes. After the reaction, add 400mL pre-cooled distilled water, adjust the pH value of the solution to 7.5 with 2mol / L NaOH, add 95% ethanol until the final concentration of ethanol is 75% for alcohol precipitation, polysaccharides are redissolved in distilled water, and the molecular weight cut-off It was dialyzed for 72 hours with a 30kD ultrafiltration membrane, concentrated under reduced pressure at 50°C, and freeze-dried to obtain sulfated schizophyllan (S-SPG1). figure 2 It is the infrared spectrogram of embodiment 1 product S-SPG1. compared to figure 1 , S-SPG1 has new cha...

Embodiment 2

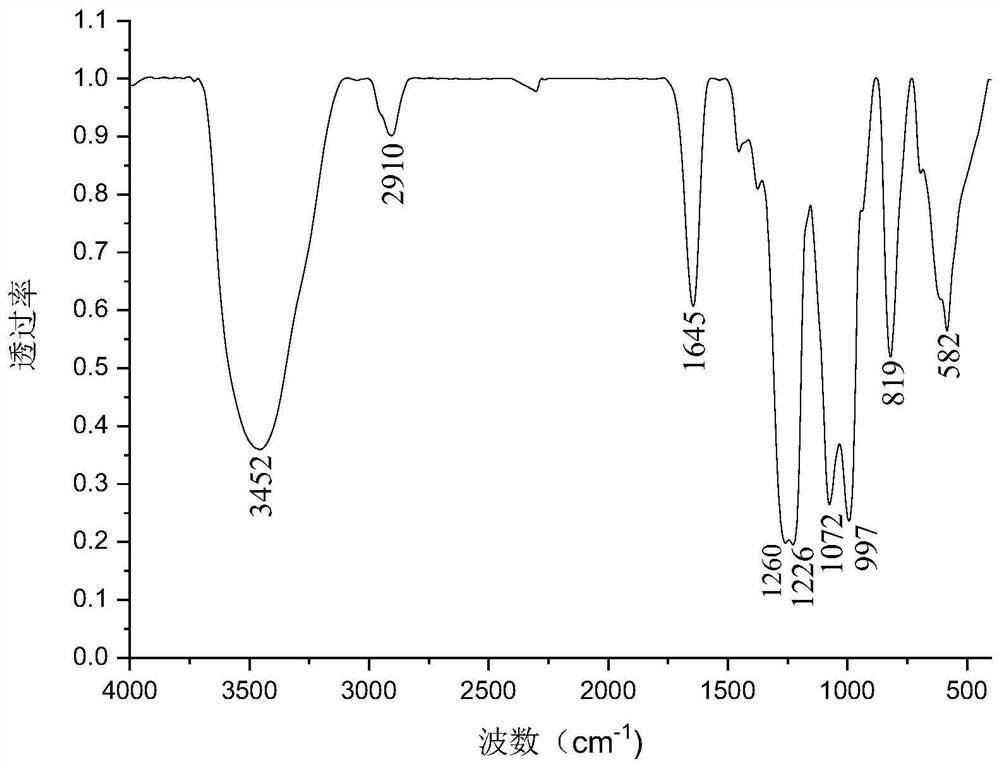

[0047] Take 6g of dried Schizophyllan, put it into a screw-necked Erlenmeyer flask, add 960mL DMF, and infiltrate it in a dry environment for 14h. Add 24.0 g of pyridine sulfur trioxide, react in a water bath at 60° C. for 1 h, and stir at 900 rpm. Then quickly lower the temperature to 10°C, add concentrated sulfuric acid twice the mass of the dry Schizophyllan, and continue the reaction for 40 minutes. After the reaction, add 1200mL pre-cooled distilled water, adjust the pH value of the solution to 7.0 with 4mol / L NaOH, add 95% ethanol until the final concentration of ethanol is 60% for alcohol precipitation. It was dialyzed for 84 hours with a 5kD ultrafiltration membrane, concentrated under reduced pressure at 45°C, and freeze-dried to obtain sulfated schizophyllan (S-SPG2). The infrared characterization of S-SPG2 is shown in the figure below. image 3 It is the infrared spectrogram of embodiment 2 product S-SPG2. compared to figure 1 , S-SPG2 at 1260~1210cm -1 , 840~8...

Embodiment 3

[0049] Take 3g of dried Schizophyllan, put it into a screw-necked Erlenmeyer flask, add 540mL DMF, and infiltrate it in a dry environment for 8h. Add 18.0 g of pyridine sulfur trioxide, react in a water bath at 80° C. for 4 h, and stir at 800 rpm. Then rapidly lower the temperature to 0°C, add concentrated sulfuric acid three times the mass of the dried Schizophyllan, and continue the reaction for 30 minutes. After the reaction, add 600mL pre-cooled distilled water, adjust the pH value of the solution to 8.0 with 2.5mol / L NaOH, add 95% ethanol until the final concentration of ethanol is 80% for alcohol precipitation, and redissolve the polysaccharide in distilled water. Dialyzed by a 3kD ultrafiltration membrane for 96 hours, concentrated under reduced pressure at 40°C, and freeze-dried to obtain sulfated schizophyllan (S-SPG3). Figure 4 It is the infrared spectrogram of embodiment 3 product S-SPG3. compared to figure 1 , S-SPG2 is also at 1260~1210cm -1 , 840~810cm -1 ,...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Solubility | aaaaa | aaaaa |

| Molecular weight | aaaaa | aaaaa |

| Molecular weight | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com