Bio-based ionic gel as well as preparation method and application thereof

An ion gel, bio-based technology, applied in the field of hydrogel, can solve the problems of limited application and low conductivity, and achieve the effect of enhancing ionic conductivity and improving ionic conductivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0029] The present invention provides a preparation method of the bio-based ion gel described in the above technical solution, comprising the following steps:

[0030] Mixing methacrylic anhydride sodium alginate monomer, water, ionic liquid, photocrosslinking agent, photoinitiator and hollow tube structure material to obtain photosensitive resin;

[0031] aligning the hollow tube structure material in the photosensitive resin, and obtaining sodium alginate ion gel after photocuring;

[0032] The sodium alginate ion gel is dried to obtain a bio-based ion gel.

[0033] In the present invention, unless otherwise specified, all raw materials are commercially available products well known to those skilled in the art.

[0034] The invention mixes methacrylic anhydride sodium alginate monomer, water, ionic liquid, photocrosslinking agent, photoinitiator and hollow tube structure material to obtain photosensitive resin. In the present invention, the preparation method of the methac...

Embodiment 1

[0052] Dissolve 0.05 g of the methacrylic anhydride sodium alginate monomer in 2.45 mL of deionized water and 1.35 g of 1-ethyl-3-methylimidazolium acetate ionic liquid, stir and mix to form a homogeneous solution; then Add 30 mg of dimethylaminoethyl methacrylate, 3 μL of 2-hydroxy-2-methyl-1-phenyl-1-propanone and 2.5 mg of catkins, and stir overnight to obtain a photosensitive resin.

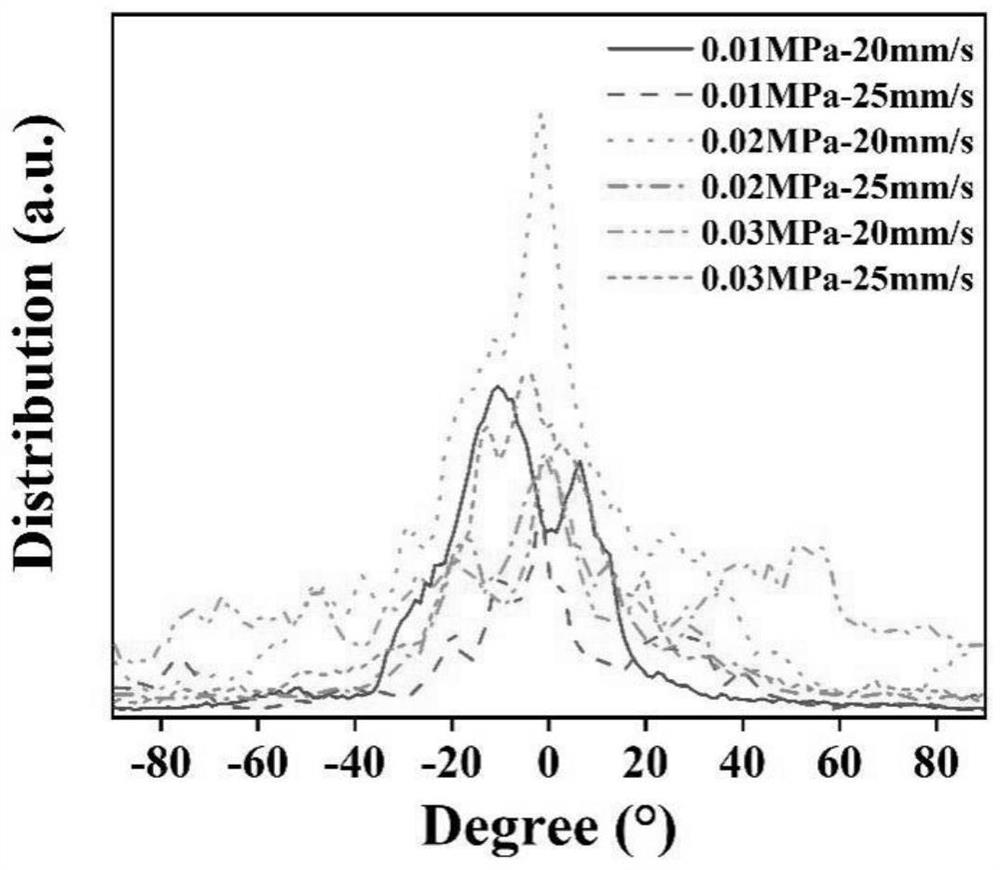

[0053] The photosensitive resin is poured into a 5mL printing syringe, the extrusion air pressure is 0.03MPa during printing, the needle moving speed is 25mm / s when printing, and the printing angle is 0°. 2 ) to solidify to obtain sodium alginate ion gel;

[0054] The sodium alginate ion gel was dried under vacuum at 40° C. for 3 days to obtain a bio-based ion gel.

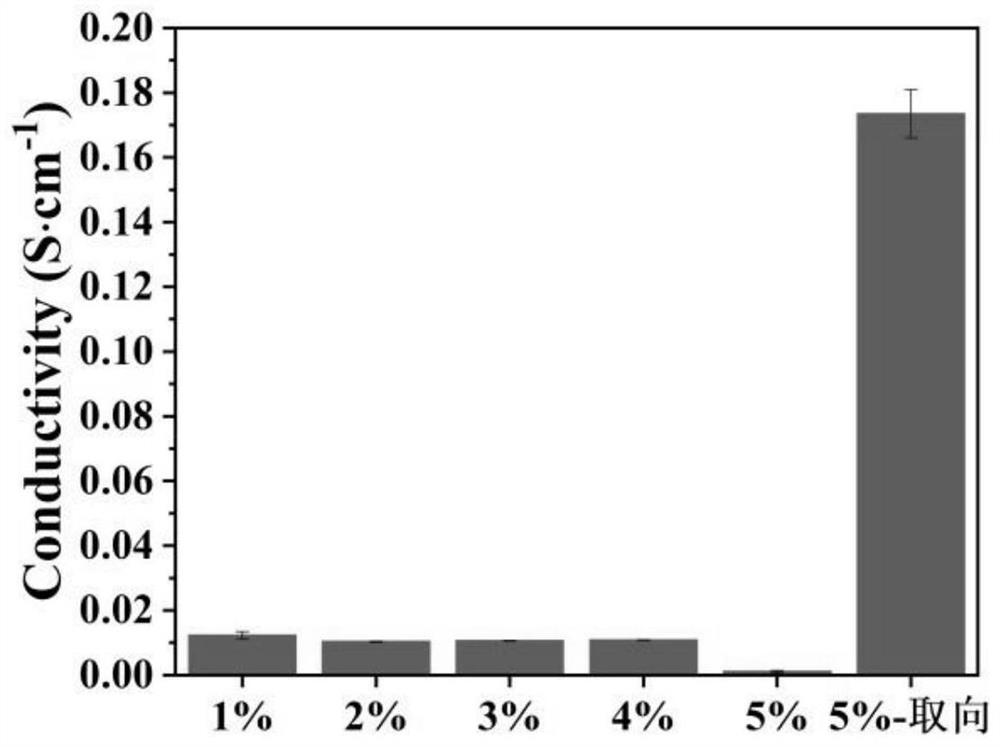

[0055] The ion conductivity of the bio-based ion gel prepared in this example is 0.17 S / cm.

Embodiment 2

[0057] Dissolve 0.05 g of the methacrylic acid anhydride sodium alginate monomer prepared in Example 1 in 2.45 mL of deionized water and 1.35 g of 1-ethyl-3-methylimidazolium acetate ionic liquid, stir and mix to form homogeneous solution; then add 30 mg dimethylaminoethyl methacrylate, 3 μL 2-hydroxy-2-methyl-1-phenyl-1-propanone and 1 mg catkin, stir overnight to obtain a photosensitive resin.

[0058] The photosensitive resin is poured into a 5mL printing syringe, the extrusion air pressure is 0.03MPa during printing, the needle moving speed is 25mm / s when printing, and the printing angle is 0°. 2 ) to solidify to obtain sodium alginate ion gel;

[0059] The sodium alginate ion gel was dried under vacuum at 40° C. for 3 days to obtain a bio-based ion gel.

[0060] The ion conductivity of the bio-based ion gel prepared in this example is 0.06 S / cm.

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| electrical conductivity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com