Cobaltous oxide nanosheet-sponge nickel/metal lithium composite material as well as preparation method and application thereof

A technology of cobaltous oxide nanometer and composite materials, which is applied in the direction of electrical components, battery electrodes, circuits, etc., can solve the problems of dendrite growth, battery performance degradation, battery interface interruption, etc., to achieve energy density, increase load capacity, The effect of low overpotential

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

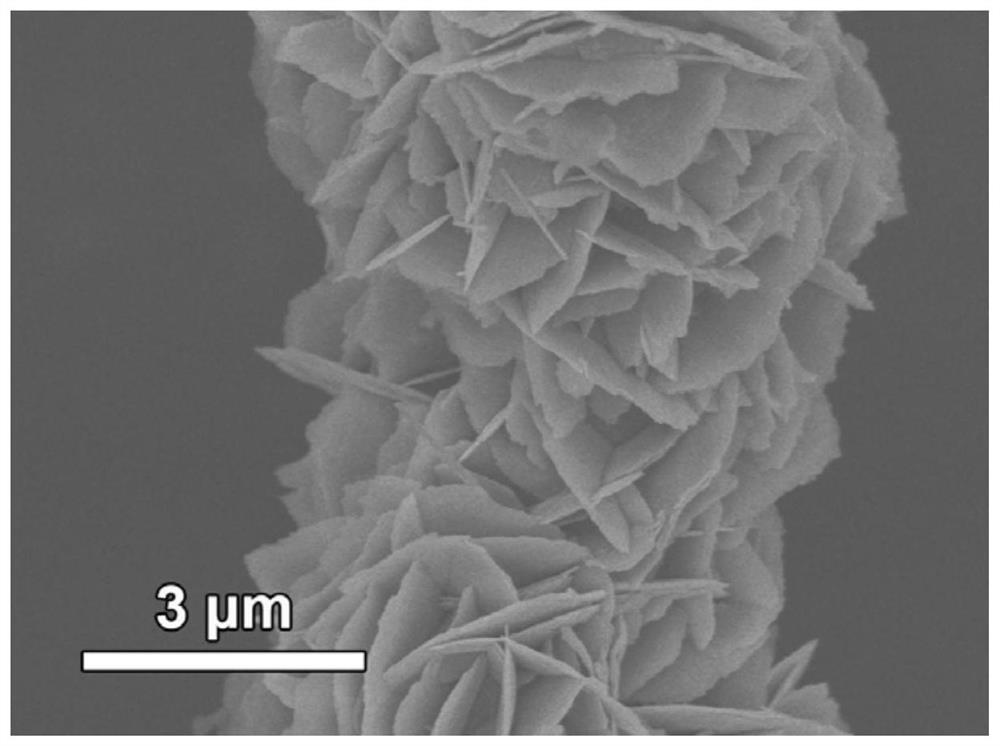

[0032] This embodiment provides a preparation method of cobaltous oxide nanosheet-sponge nickel / lithium metal composite material, comprising the following steps:

[0033] (1) configure nickel acetate aqueous solution

[0034] 0.871g of Ni(AC) 2 4H 2 O was added to 70 mL of deionized water and stirred at room temperature for 30 min to prepare a nickel acetate aqueous solution with a concentration of 0.05 mol / L;

[0035] (2) Configure reaction solution A

[0036] Add 7 mL of N to the nickel acetate aqueous solution prepared in step (1) 2 h 4 ·H 2 O and stirred for 15min to obtain reaction solution A;

[0037] (3) Preparation of sponge nickel base material

[0038] Pour the reaction solution A into a 100mL liner and put it into a hydrothermal reaction kettle, heat it to 100°C for 10 hours; after the reaction is completed, take out the base material and wash it with deionized water for 3 times, freeze-dry it for 12 hours to obtain a sponge nickel base material ;

[0039] ...

Embodiment 2

[0046] This embodiment provides a preparation method of cobaltous oxide nanosheet-sponge nickel / lithium metal composite material, comprising the following steps:

[0047] (1) configure nickel acetate aqueous solution

[0048] 0.871g of Ni(AC) 2 4H 2 O was added to 70 mL of deionized water and stirred at room temperature for 30 min to prepare a nickel acetate aqueous solution with a concentration of 0.05 mol / L;

[0049] (2) Configure reaction solution A

[0050] Add 7 mL of N to the nickel acetate aqueous solution prepared in step (1) 2 h 4 ·H 2 O and stirred for 15min to obtain reaction solution A;

[0051] (3) Preparation of sponge nickel base material

[0052] Pour the reaction solution A into a 100mL liner and put it into a hydrothermal reaction kettle, heat it to 100°C for 10h; after the reaction is completed, take out the base material and wash it with deionized water for 3 times, and freeze-dry it for 12h to prepare the sponge nickel base material ;

[0053] (4)...

Embodiment 3

[0060] This embodiment provides a preparation method of cobaltous oxide nanosheet-sponge nickel / lithium metal composite material, comprising the following steps:

[0061] (1) configure nickel acetate aqueous solution

[0062] 0.871g of Ni(AC) 2 4H 2 O was added to 70 mL of deionized water and stirred at room temperature for 30 min to prepare a nickel acetate aqueous solution with a concentration of 0.05 mol / L;

[0063] (2) Configure reaction solution A

[0064] Add 7 mL of N to the nickel acetate aqueous solution prepared in step (1) 2 h 4 ·H 2 O and stirred for 15min to obtain reaction solution A;

[0065] (3) Preparation of sponge nickel base material

[0066] Pour the reaction solution A into a 100mL liner and put it into a hydrothermal reaction kettle, heat it to 100°C for 10h; after the reaction is completed, take out the base material and wash it with deionized water for 3 times, and freeze-dry it for 12h to prepare the sponge nickel base material ;

[0067] (4)...

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com