Method for producing building gypsum powder from ardealite

A technology of building gypsum powder and phosphogypsum, which is applied in the field of phosphogypsum reuse, can solve the problems of low purity and poor performance of calcium sulfate, achieve high strength, improve recycling rate, and simple process operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0032] (1) Phosphogypsum and absorption liquid are configured into a slurry, and the required absorption liquid comes from the solution after absorbing the tail gas of the calciner;

[0033] (2) After stirring evenly, it is separated by cyclone to obtain the overflow product and the underflow product; the overflow product is filtered, and the filtrate is filtered to absorb the exhaust gas dust of the calciner; the filter cake is dried to obtain the primary gypsum powder;

[0034] (3) The primary gypsum powder is calcined at high temperature in a calciner to obtain building gypsum powder, and the hot gas of coal combustion is used to contact the primary gypsum powder for direct calcination.

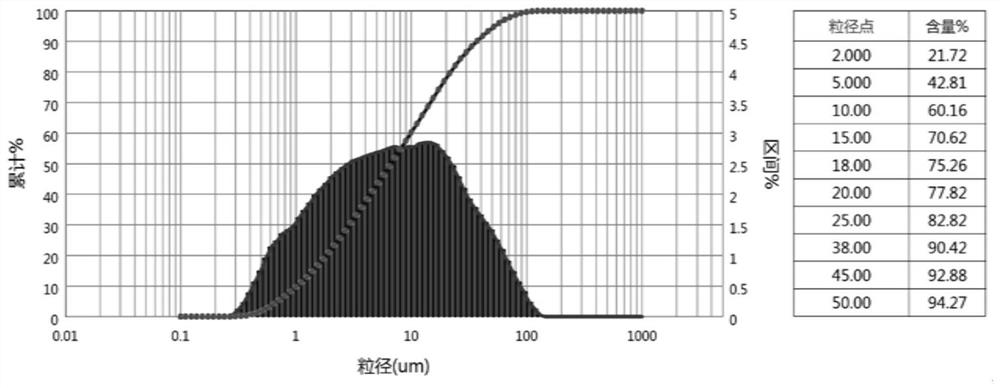

[0035] The phosphogypsum slurry is configured according to the solid-to-liquid ratio of 10%; the cyclone specification is diameter Φ1 = 150mm, the diameter of the bottom outlet Φ2 = 20mm; the operating pressure of the cyclone = 0.1MPa; the overflow product is filtered and the drying tempera...

Embodiment 2

[0038] (1) Prepare phosphogypsum and absorption liquid into a slurry, and the required absorption liquid comes from the solution after absorbing the exhaust gas of the calciner

[0039] (2) After stirring evenly, it is separated by cyclone to obtain the overflow product and the underflow product; the overflow product is filtered, and the filtrate is filtered to absorb the exhaust gas dust of the calciner; the filter cake is dried to obtain the primary gypsum powder;

[0040] (3) The primary gypsum powder is calcined at high temperature in a calciner to obtain building gypsum powder, and the hot gas of coal combustion is used to contact the primary gypsum powder for direct calcination.

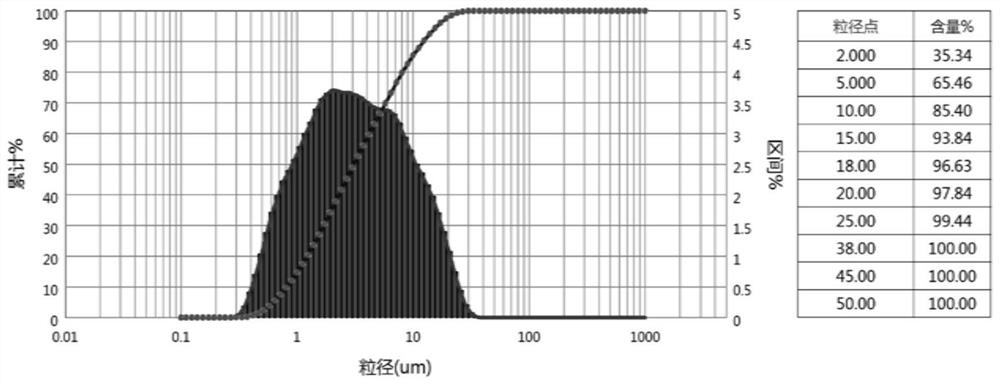

[0041] The phosphogypsum slurry is configured according to the solid-to-liquid ratio of 10%; the specification of the cyclone is diameter Φ1=75mm, the diameter of the bottom outlet Φ2=8mm; the operating pressure of the cyclone is 0.3MPa; the overflow product is filtered and the drying temperatur...

Embodiment 3

[0044] (1) Prepare phosphogypsum and absorption liquid into a slurry, and the required absorption liquid comes from the solution after absorbing the exhaust gas of the calciner

[0045] (2) After stirring evenly, it is separated by cyclone to obtain overflow product and underflow product; the overflow product is filtered, and the filtrate is filtered to absorb the exhaust gas dust of the calciner; the filter cake is dried to obtain primary gypsum powder;

[0046] (3) The primary gypsum powder is calcined at high temperature in a calciner to obtain building gypsum powder, and the hot gas of natural gas combustion is used to contact the primary gypsum powder for direct calcination.

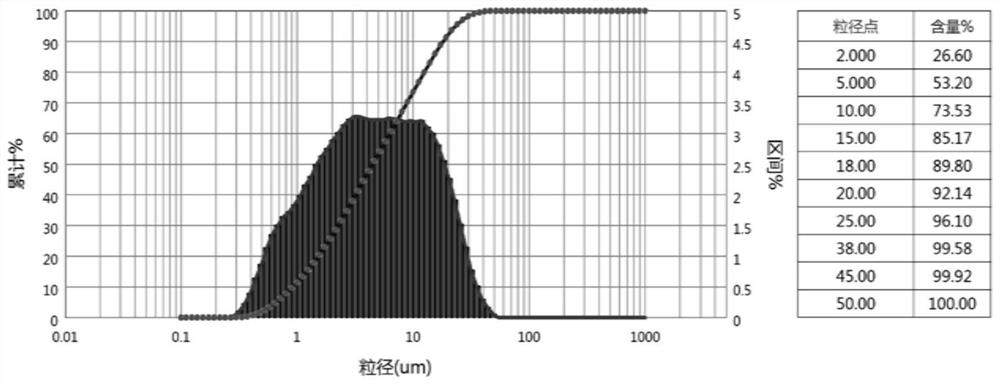

[0047] The phosphogypsum slurry is configured according to the solid-to-liquid ratio of 40%; the cyclone specification is diameter Φ1 = 150mm, the diameter of the bottom outlet Φ2 = 20mm; the operating pressure of the cyclone = 0.1MPa; the overflow product is filtered and the drying temperature is 40...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| compressive strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com