Synthesis method of carbohydrazide

A synthetic method, carbohydrazide technology, applied in organic chemistry, etc., can solve problems such as high safety operation requirements, toxic raw materials, and toxic by-products, and achieve high yield, fast reaction speed, and less side reactions.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

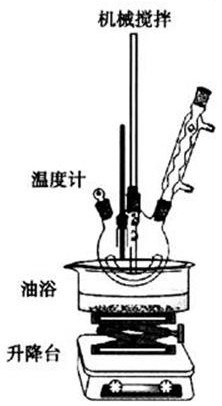

[0030] A kind of synthetic method of carbohydrazide comprises the steps:

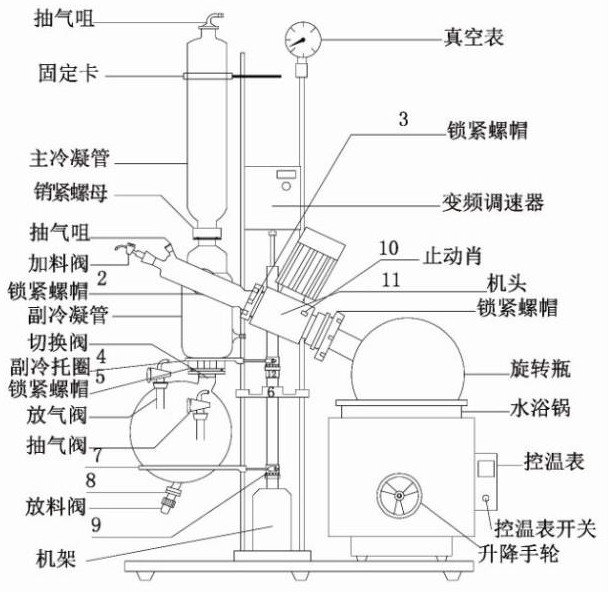

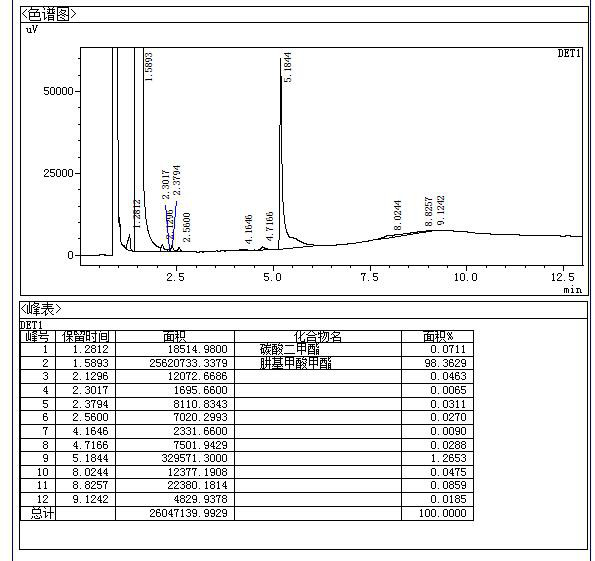

[0031] Step 1: First add 56.28g of 80% hydrazine hydrate solution to a 500ml three-necked flask, then add 90.09g of 99.9% dimethyl carbonate, turn on the magnetic stirrer, and react for 2 hours at a reaction temperature of 70°C to synthesize Methyl carbazate crude product; the synthesized methyl carbazate crude product is cooled to room temperature, weighs 142.97g of the reaction solution, uses a single-necked flask to evaporate and crystallize under reduced pressure, and distills out 65.11g of the mother liquor to obtain 77.86g of the product. The product is tested by GC, and the test results are as follows: image 3 As shown, it can be seen that the product obtained is methyl carbazate, and the product purity is 98.3%, and the product yield obtained by calculation is 96.04%.

[0032] Step 2: First add 78.29g of 80% hydrazine hydrate solution to a 500ml three-necked flask, then add 45.04g of 98.3% met...

Embodiment 2

[0034] A kind of synthetic method of carbohydrazide comprises the steps:

[0035] Step 1: First add 56.35g of 80% hydrazine hydrate solution into a 500ml three-neck flask, then add 90.13g of 99.9% dimethyl carbonate, turn on the magnetic stirrer, and react for 2 hours at a reaction temperature of 60°C to synthesize hydrazine groups Crude methyl formate; cool the synthesized crude methyl carbazate to room temperature, weigh 142.64 g of the reaction solution, use a single-necked flask to evaporate and crystallize under reduced pressure, distill 63.09 g of the mother liquor, and obtain 79.55 g of the methyl carbazate product, The product purity is 98.8%, and the yield is 98.1%.

[0036] Step 2: First add 60.07g of 80% hydrazine hydrate solution to a 500ml three-neck flask, then add 72.07g of 98.8% methyl carbazate, turn on the magnetic stirrer, and react for 6 hours at a reaction temperature of 85°C to synthesize carbon Crude hydrazide: cool the synthesized crude carbohydrazide ...

Embodiment 3

[0038] A kind of synthetic method of carbohydrazide comprises the steps:

[0039] Step 1: First add 56.31g of 80% hydrazine hydrate solution to a 500ml three-necked flask, then add 90.08g of 99.9% dimethyl carbonate, turn on the magnetic stirrer, and react for 2 hours at a reaction temperature of 50°C to synthesize hydrazine groups Crude methyl formate; cool the synthesized crude methyl carbazate to room temperature, weigh 143.65 g of the reaction solution, use a single-necked flask to evaporate and crystallize under reduced pressure, and distill 64 g of the mother liquor to obtain 79.65 g of the methyl carbazate product. The purity is 99.1%, and the yield is 98.2%.

[0040] Step 2: First add 78.35g of 80% hydrazine hydrate solution to a 500ml three-neck flask, then add 45.08g of 99.1% methyl carbazate, turn on the magnetic stirrer, and react for 5 hours at a reaction temperature of 85°C to synthesize carbon Hydrazide crude product: cool the synthesized carbohydrazide crude p...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com