Cross-linked PVC foam waste artificial board and preparation method thereof

A foam waste and wood-based panel technology, applied in the field of composite materials, can solve the problems of high glue consumption and product density, environmental hazards, and inability to secondary processing, etc., to achieve the goals of reducing the amount of glue, improving moisture resistance, and improving mechanical properties Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

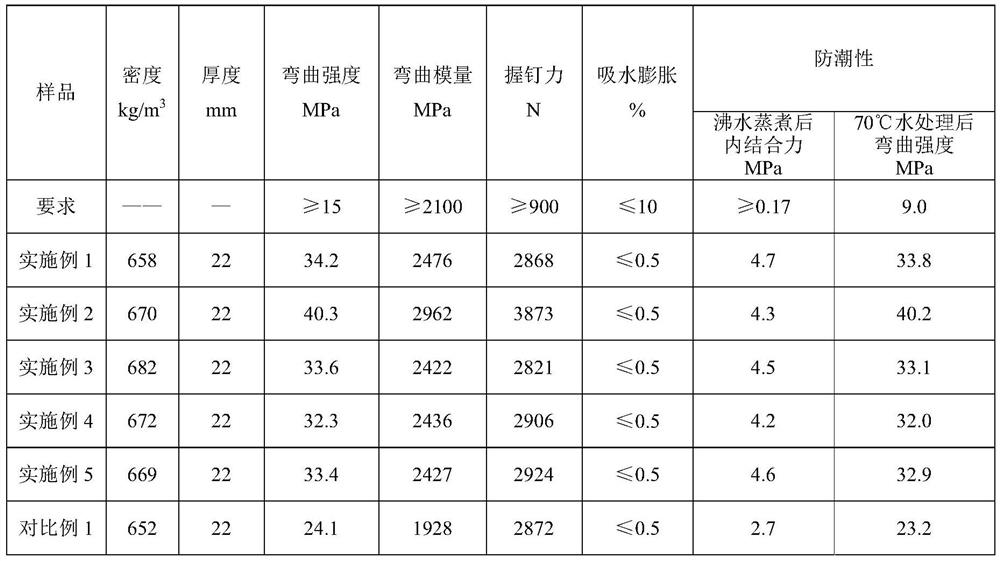

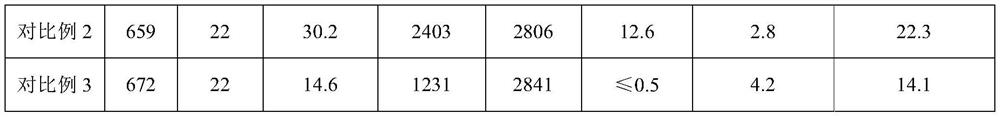

Examples

Embodiment 1

[0026] The formula is 100 parts of cross-linked PVC foam waste powder, 5 parts of KH560 coupling agent, 10 parts of adhesive, wherein the adhesive formula is 100 parts of 4110 polyether polyol, 150 parts of PM-200 polymethyl polyphenyl Isocyanate, 100 parts E51 epoxy resin, 50 parts water content 10% methyl hexahydrophthalic anhydride. The process is:

[0027] S1: Pour the cross-linked PVC foam waste powder and coupling agent into the planetary stirring tank, and mix for 5 minutes;

[0028] S2: Add the prepared adhesive into the planetary stirring tank and mix for 5 minutes;

[0029] S3: Divide the stirred material into 4 parts, and lay a layer of reinforcing ribs for each part into the mold, wherein the reinforcing ribs are bamboo sticks with a diameter of 2 mm;

[0030] S4: Place the mold on a single-layer flat vulcanizing machine, pressurize at 10MPa, and keep the pressure at room temperature for 5 minutes;

[0031] S5: Take out the pre-pressed plate from the mold, trans...

Embodiment 2

[0033] The formula is 100 parts of cross-linked PVC foam waste powder, 5 parts of KH560 coupling agent, 10 parts of adhesive, wherein the adhesive formula is 100 parts of 4110 polyether polyol, 150 parts of PM-200 polymethyl polyphenyl Isocyanate, 100 parts E51 epoxy resin, 50 parts water content 10% methyl hexahydrophthalic anhydride. The process is:

[0034] S1: Pour the cross-linked PVC foam waste powder and coupling agent into the planetary stirring tank, and mix for 5 minutes;

[0035] S2: Add the prepared adhesive into the planetary stirring tank and mix for 5 minutes;

[0036] S3: Divide the stirred material into 4 parts, and lay a layer of reinforcing ribs for each part into the mold, wherein the reinforcing ribs are waste blade skins with a width of 3 mm;

[0037] S4: Place the mold on a single-layer flat vulcanizing machine, pressurize at 10MPa, and keep the pressure at room temperature for 5 minutes;

[0038] S5: Take out the pre-pressed plate from the mold, tran...

Embodiment 3

[0040] The formula is 100 parts of cross-linked PVC foam waste powder, 5 parts of KH560 coupling agent, 10 parts of adhesive, wherein the adhesive formula is 100 parts of 4110 polyether polyol, 150 parts of PM-200 polymethyl polyphenyl Isocyanate, 100 parts E51 epoxy resin, 50 parts water content 10% methyl hexahydrophthalic anhydride. The process is:

[0041] S1: Pour the cross-linked PVC foam waste powder and coupling agent into the planetary stirring tank, and mix for 5 minutes;

[0042] S2: Add the prepared adhesive into the planetary stirring tank and mix for 5 minutes;

[0043] S3: Divide the stirred material into 4 parts, and lay a layer of reinforcing ribs for each part poured into the mold, wherein the reinforcing ribs are glass fiber mesh cloth with a hole diameter of 5 mm;

[0044] S4: Place the mold on a single-layer flat vulcanizing machine, pressurize at 10MPa, and keep the pressure at room temperature for 5 minutes;

[0045] S5: Take out the pre-pressed plate...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

| Aperture | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com