Gas generating agent composition, gas generating agent, preparation method and application

A technology of gas generating agent and composition, which is applied in the directions of inorganic oxyhalide salt explosive composition, attack equipment, vehicle safety arrangement, etc., and can solve problems such as inability to meet limit requirements.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

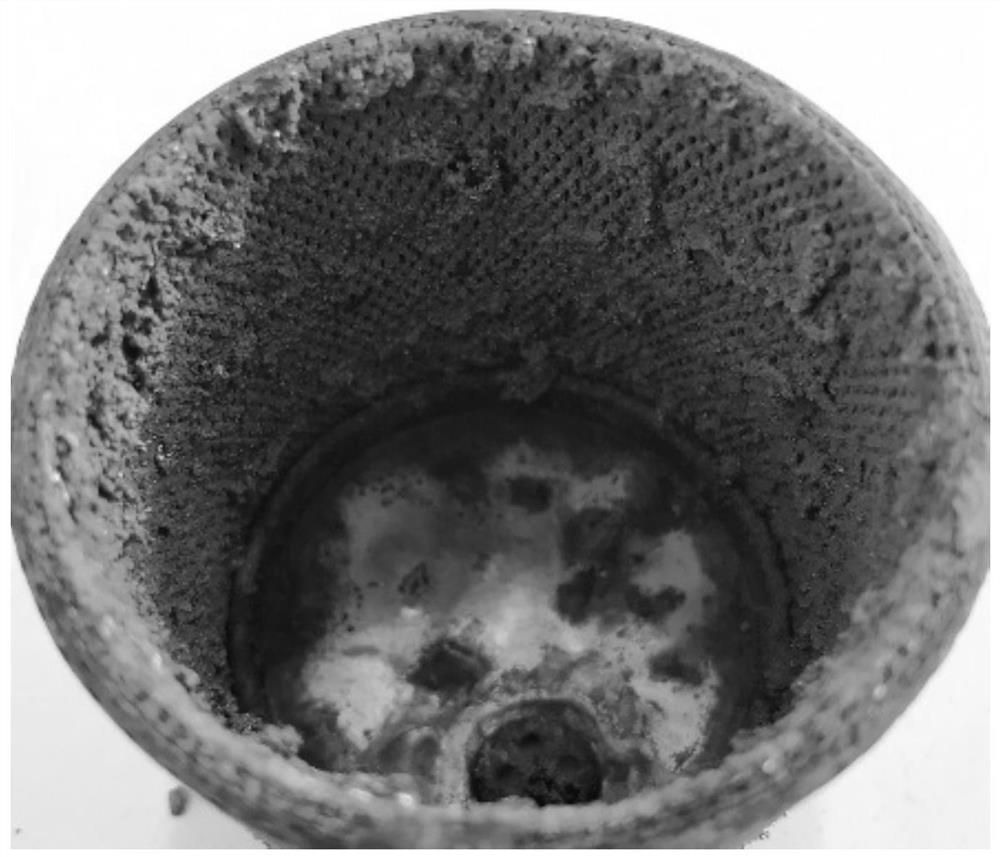

Image

Examples

Embodiment approach

[0052] As an embodiment, the specific preparation method of the gas generating agent includes the following steps:

[0053] (1) Mix guanidine nitrate, basic copper nitrate, ammonium perchlorate and zirconate in a mixing equipment. The mixing equipment can be a pneumatic mixer, a V-type mixer, a three-dimensional multi-directional motion mixer, an automatic lifting Hopper mixer, vibrating mill, ribbon mixer or acoustic resonance mixer, mixing time ≥ 5min to obtain the first material.

[0054] (2), add distilled water to the first material and carry out wet mixing, the equipment for wet mixing is a kneader or a mixer, for example, a horizontal kneader, a vertical kneader, a ribbon mixer or an acoustic resonance mixer can be selected, The amount of water added is 5% to 15% of the total mass of the first material, and the wet mixing time is 20 minutes to 60 minutes to obtain the second material.

[0055] (3) passing the second material through a 10-40 mesh screen to obtain a thir...

Embodiment 1

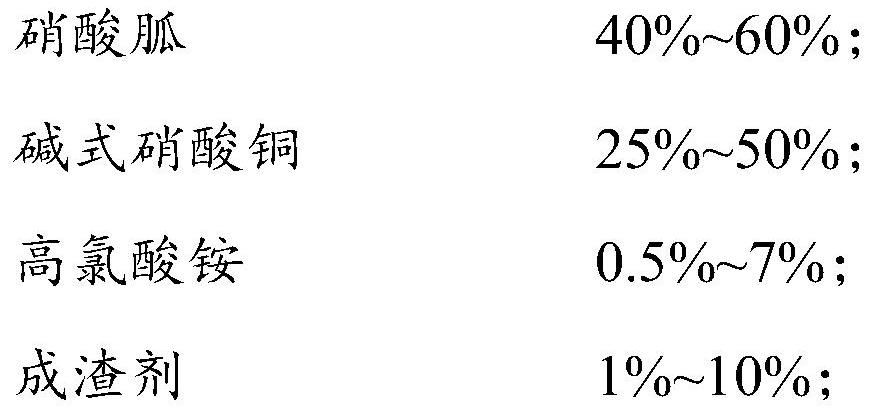

[0070] This embodiment provides a gas generating agent, which is a disc with a diameter of 5 mm and a thickness of 1.9 mm, and is composed of a gas generating agent composition and a lubricant. The gas generating agent composition is composed of 54% guanidine nitrate, basic nitric acid Composed of 38% copper, 2% ammonium perchlorate and 6% barium zirconate, the oxygen balance of the gas generating agent composition is -0.96%; the lubricant is calcium stearate, and the consumption is 1% of the total amount of the gas generating agent composition %.

[0071] The preparation process of the gas generating agent is:

[0072] Mix guanidine nitrate, basic copper nitrate, ammonium perchlorate and barium zirconate through mixing equipment to obtain the first material; add 15% distilled water to the first material and carry out wet kneading for 60 minutes to obtain the second material; The material passes through a 40-mesh screen to obtain a third material; the third material is dried un...

Embodiment 2

[0096] This embodiment provides a gas generating agent, which is basically the same as the preparation method in Example 1, except that the mass percentage of the gas generating agent composition in this embodiment consists of: guanidine nitrate 52%; basic copper nitrate 42%; ammonium perchlorate 2%; barium zirconate 4%, the oxygen balance of the gas generant composition formulation is -0.353%.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com