Hybrid TPU capable of quickly crystallizing and having low refractive index and preparation method of hybrid TPU

A technology of refractive index and hybridization, which is applied in the field of polyurethane, can solve the problems of reducing visual acuity, color contrast, visual clarity and visual comfort, affecting driving sight, and potential safety hazards, so as to increase visual acuity and improve crystallization The effect of increasing the speed and increasing the difficulty of processing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0027] A kind of preparation method of above-mentioned hybrid TPU composition that can crystallize rapidly, low refractive index, also comprise the following steps:

[0028] (1) According to the method described in patent CN107417973B, the surface of hollow silica nanospheres is modified with higher carbon alcohol;

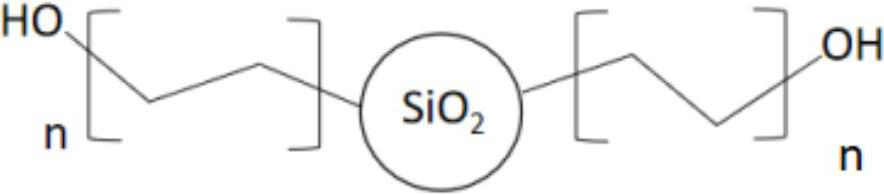

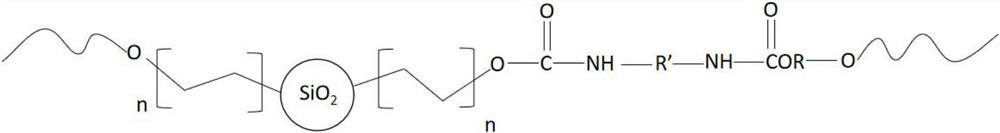

[0029] (2) Add isocyanate (MDI) and hollow silica nano-microspheres, catalyst to the reactor under nitrogen protection and heating to prepare hollow silica microsphere hybrid TPU prepolymer, the mass fraction of isocyanate is 28-35%; the mass fraction of the hollow silica microspheres is 4-6%; 2-4 drops of the catalyst are dripped with a straw; the heating temperature is preferably 85-95°C; The specific structure of TPU hybridized with silicon nanospheres is:

[0030]

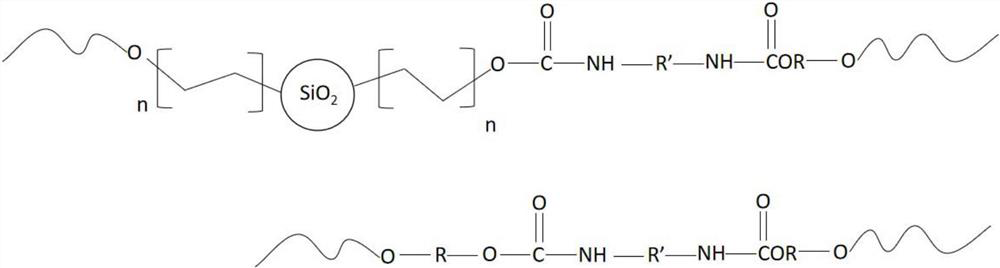

[0031] Under nitrogen protection and continuous heating, and continuous stirring, continue to add polyether or polyester diol, 1,4-butanediol to step (2), and react for 24 to 36 hours to prepar...

Embodiment 1

[0050] Embodiment 1 preparation method is as follows:

[0051] (1) According to the method described in patent CN 107417973 B, the surface of hollow silica nanospheres is modified with higher carbon alcohol;

[0052] (2) Add 27.5wt% isocyanate (MDI) and 2.8wt% hollow silica nanospheres, 0.3% dibutyltin dilaurate and triethylamine to the reactor under nitrogen protection and heating (85-95°C) Catalyst to prepare hollow silica microsphere hybrid TPU;

[0053] (3) Under nitrogen protection and continued heating (85-95° C.), and with continuous stirring, continue to add 65 wt % of polyether diol (PTMEG3000), 5.8 wt % of 1,4-butane to step (2) The diol is reacted for 24-36 hours to prepare TPU with excess NCO, and the mole number of the isocyanate group is equivalent to the total number of moles of higher carbon alcohol, polyether or polyester diol, and 1,4-butanediol.

[0054] Table 1:

[0055]

[0056] MDI: diphenylmethane diisocyanate, Wanhua Chemical;

[0057] PTMEG3000:...

PUM

| Property | Measurement | Unit |

|---|---|---|

| crystallization temperature | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com