Preparation method and application of alloy monatomic catalyst

A catalyst, copper catalyst technology, applied in chemical instruments and methods, metal/metal oxide/metal hydroxide catalyst, oxidation to prepare carbonyl compounds, etc., can solve problems such as poor activity, low ethanol conversion rate, and poor catalyst stability , to achieve the effect of low cost, high reaction efficiency and good stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

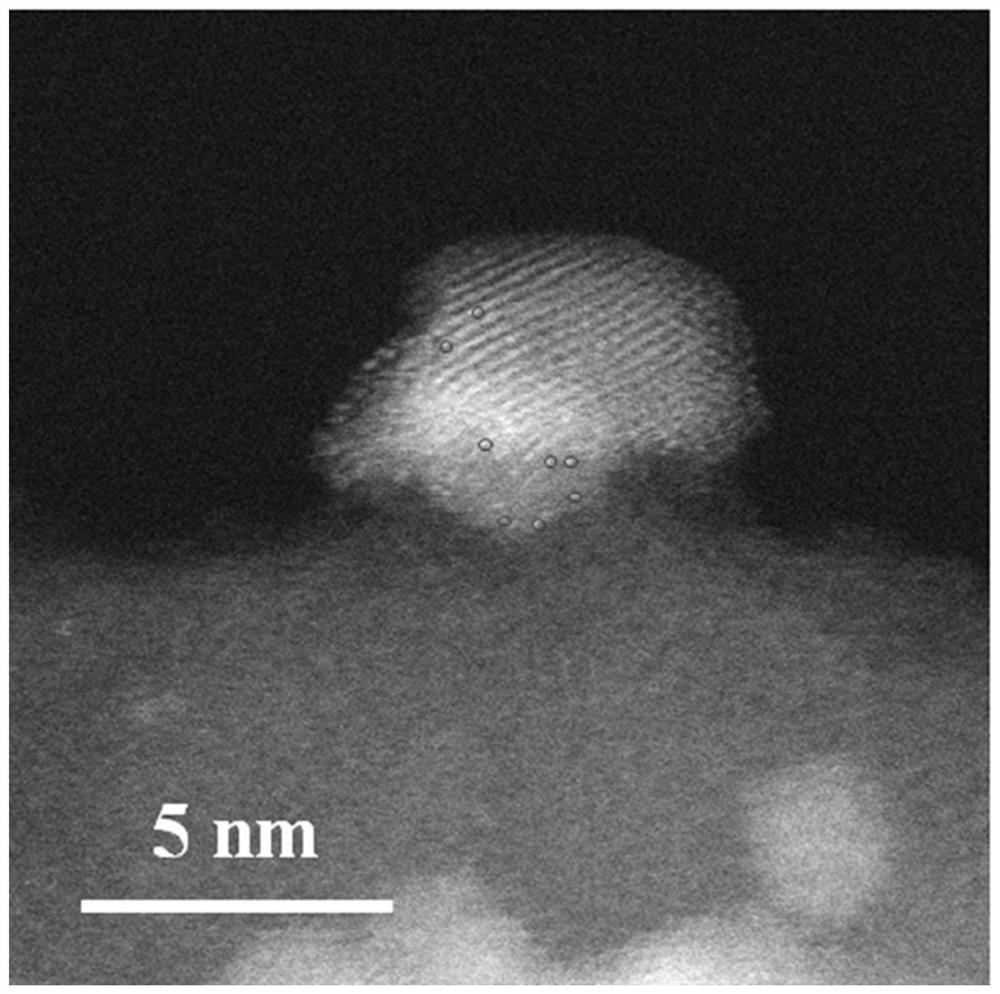

Image

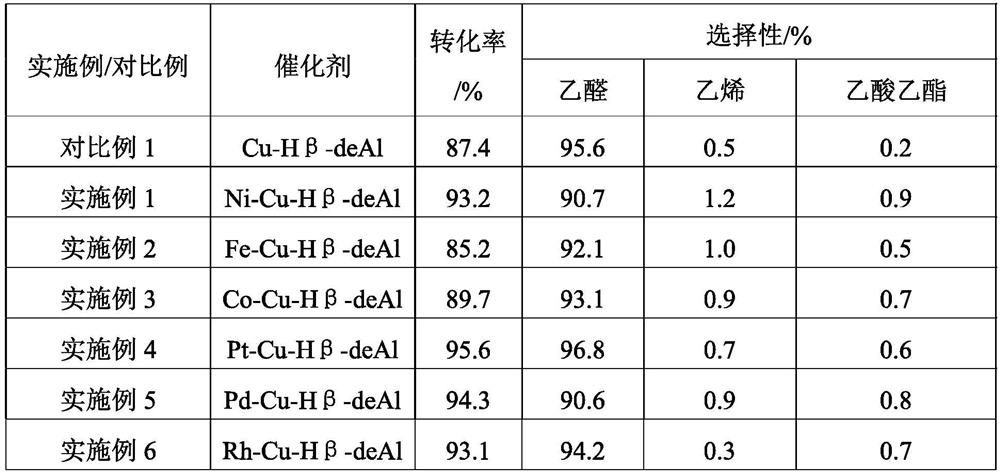

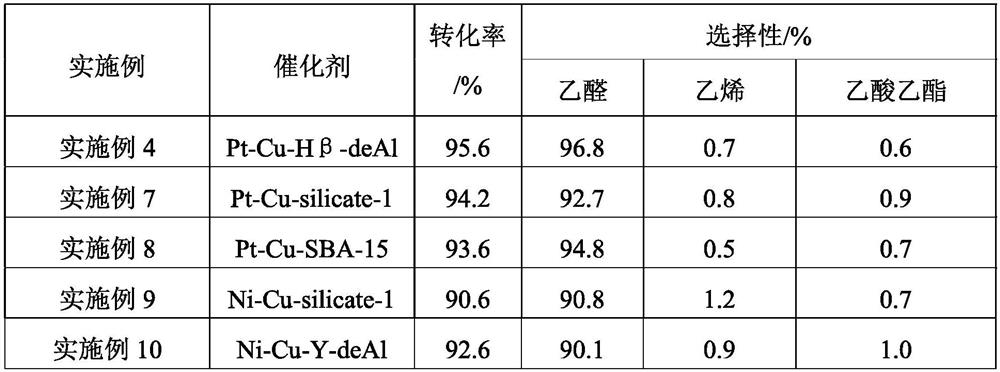

Examples

Embodiment 1

[0043] Carrier handling:

[0044] Take Hβ molecular sieve with a silicon-aluminum ratio of 25 as an example: 10 g of Hβ molecular sieve was weighed and added to 100 mL of 66% nitric acid solution, and treated at 80° C. for 24 hours. Then, it is filtered, washed, and calcined at 550° C. for 3 hours to obtain a dealuminated Hβ molecular sieve. The aluminum content of the sample after dealuminated is determined by XRF to be less than 1 wt%.

[0045] Preparation of Copper-Based Catalyst: Preparation of Cu-Hβ-deAl Catalyst by Ammonia Distillation

[0046] Using copper acetate as the precursor, the process of preparing the catalyst by ammonia distillation is as follows: Weigh 3.1 g of copper acetate, add it to a three-necked flask containing 70 mL of distilled water, stir until it is completely dissolved, then slowly add 16 mL of ammonia water with a mass fraction of 25%, At this time, the pH of the solution was 11-12, and the solution was sealed and stirred vigorously for 90 minut...

Embodiment 2

[0050] Embodiment 2 is only different from Embodiment 1 in that the second metal is Fe;

Embodiment 3

[0051] Embodiment 3 is only different from Embodiment 1 in that the second metal is Co;

PUM

| Property | Measurement | Unit |

|---|---|---|

| crystallinity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com