Biodegradable Carbomer core-shell structure polymer microsphere, preparation method and application thereof

A technology of biodegradation and core-shell structure, which is applied in the field of carbo-like core-shell structure polymer microspheres and its preparation, can solve the problems affecting practical application and the decline of storage performance of biodegradable carbo resin, and achieve good storage performance and the effect of using performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0048] A preparation method of biodegradable carbogen-like core-shell polymer microspheres, comprising the steps of:

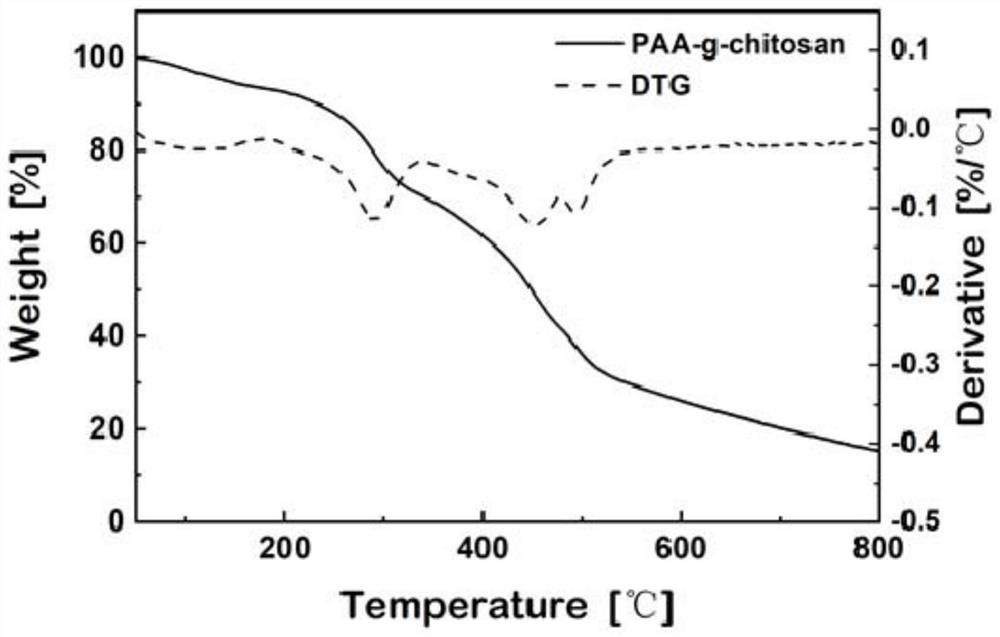

[0049] Chitosan microspheres, potassium persulfate and methylenebisacrylamide were added to the acrylic acid solution, reacted at 55°C for 6h under a nitrogen atmosphere, centrifuged, washed with ethanol, and vacuum-dried at 60°C for 24h to obtain polymer microspheres;

[0050]The mass ratio of chitosan microspheres, potassium persulfate, methylene bisacrylamide and acrylic acid is 1:0.15:0.15:10;

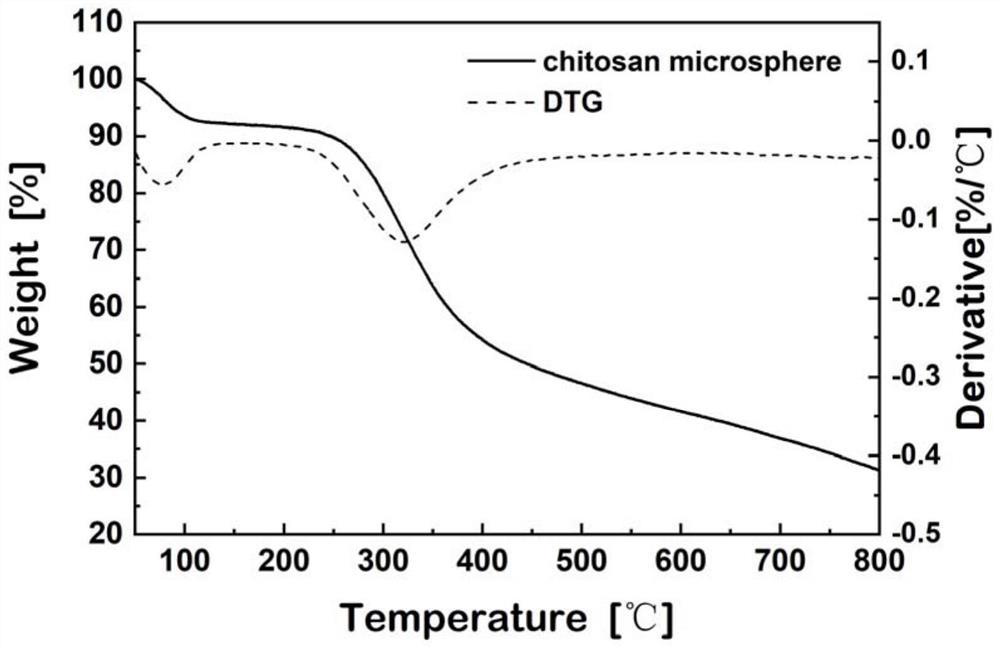

[0051] The preparation method of chitosan microsphere described in the present embodiment, comprises the steps:

[0052] S11. Configure the reverse phase suspension:

[0053] S111. Add 4.97g of Span 80 into a two-necked flask filled with 100ml of liquid paraffin, and mechanically stir for 30min to obtain an oil phase;

[0054] S112. adding 1 g of chitosan to 50 ml of a 2% glacial acetic acid solution, and ultrasonically stirring to obtain an aqueous chitosan phas...

Embodiment 2

[0058] A preparation method of biodegradable carbogen-like core-shell polymer microspheres, comprising the steps of:

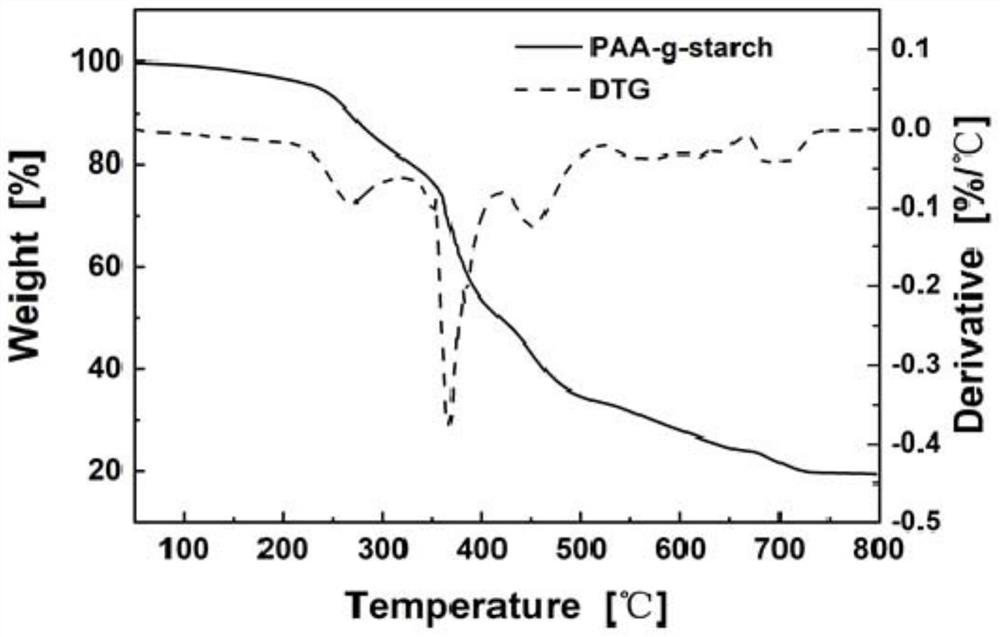

[0059] Starch microspheres, potassium persulfate and methylenebisacrylamide were added to the acrylic acid solution, reacted at 55°C for 6h under nitrogen atmosphere, centrifuged, washed with ethanol, and vacuum-dried at 60°C for 24h to obtain polymer microspheres;

[0060] The mass ratio of the starch microspheres, potassium persulfate, methylenebisacrylamide and acrylic acid is 1:0.15:0.15:10;

[0061] The preparation method of starch microspheres described in the present embodiment may further comprise the steps:

[0062] S11. Configure the reverse phase suspension:

[0063] S111. Add 7.5g of Span 80 into a two-neck flask filled with 150ml of liquid paraffin, and mechanically stir for 30min to obtain an oil phase;

[0064] S112. Add 1 g of soluble starch into 22 ml of deionized water, stir at 80°C to make it fully gelatinized, and obtain an aqueous starch...

Embodiment 3

[0068] A preparation method of biodegradable carbogen-like core-shell polymer microspheres, comprising the steps of:

[0069] Add carboxymethyl cellulose microspheres, potassium persulfate and methylene bisacrylamide to the acrylic acid solution, react for 6 hours at 55°C under a nitrogen atmosphere, centrifuge, wash with ethanol, and vacuum dry at 60°C for 24 hours to obtain polymer microspheres. ball;

[0070] The mass ratio of the carboxymethyl microspheres, potassium persulfate, methylenebisacrylamide and acrylic acid is 1:0.15:0.15:10;

[0071] The preparation method of carboxymethyl microspheres described in the present embodiment comprises the steps:

[0072] S11. Configure the reverse phase suspension:

[0073] S111. Add 7.5g of Span 80 into a two-neck flask filled with 150ml of liquid paraffin, and mechanically stir for 30min to obtain an oil phase;

[0074] S112. Add 1 g of carboxymethyl cellulose into 22 ml of deionized water, stir well to dissolve it, and obtain...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com