Novel reflective coating material and preparation method thereof

A reflective coating, a new type of technology, applied in reflective/signal coatings, fireproof coatings, coatings, etc., can solve the problems of low diffuse reflectance, excessive surface roughness, etc., and achieve high reflectivity, good brightness, and strong adhesion Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

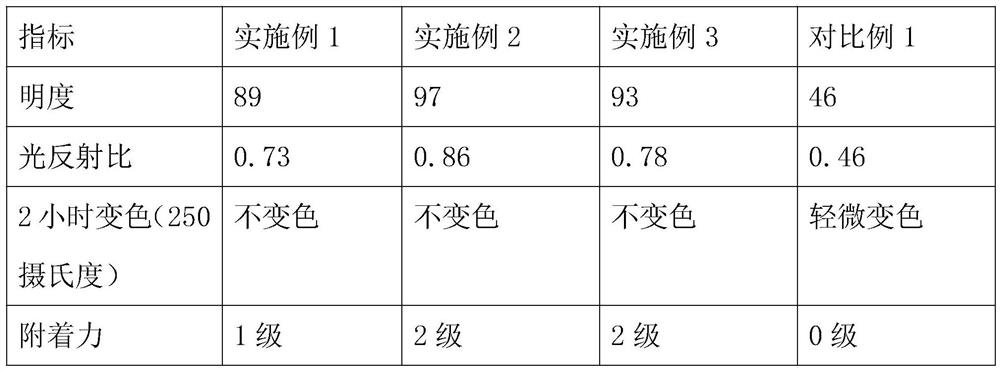

Examples

Embodiment 1

[0040] A novel reflective paint, comprising the following raw materials in weight ratio:

[0041] 1 part of hydroxyethyl cellulose;

[0042] Elastic acrylic emulsion 15 parts;

[0043] Silicone acrylic emulsion 50 parts;

[0044] 8 parts urea-formaldehyde resin

[0045] 2 parts of nano titanium dioxide;

[0046] 100 parts of water;

[0047] 2 parts of dispersant;

[0048] 0-1 part of pH regulator;

[0049] 50 parts of titanium dioxide;

[0050] Leveling agent 5 parts;

[0053] Heavy calcium 100 parts;

[0054] Acrylic emulsion 50 parts;

[0055] 1 part of thickener;

[0056] 10 parts of film-forming aids;

[0057] 5 parts of pigment.

Embodiment 2

[0059] A novel reflective paint, comprising the following raw materials in weight ratio:

[0060] 1.2 parts of hydroxyethyl cellulose;

[0061] Elastic acrylic emulsion 18 parts;

[0062] Silicone acrylic emulsion 45 parts;

[0063] 11 parts of urea-formaldehyde resin

[0064] 3 parts of nano titanium dioxide;

[0065] 150 parts of water;

[0066] 3 parts of dispersant;

[0067] 0-1 part of pH regulator;

[0068] 75 parts of titanium dioxide;

[0069] Leveling agent 7 parts;

[0070] Barium sulfate 10 parts

[0072] Heavy calcium 150 parts;

[0073] Acrylic emulsion 150 parts;

[0074] 3 parts of thickener;

[0075] 15 parts of film-forming aids;

[0076] 12 parts of pigment.

Embodiment 3

[0078] A novel reflective paint, comprising the following raw materials in weight ratio:

[0079] 1.5 parts of hydroxyethyl cellulose;

[0080] 20 parts of elastic acrylic emulsion;

[0081] Silicone acrylic emulsion 40 parts;

[0082] 15 parts urea-formaldehyde resin

[0083] 4 parts of nano titanium dioxide;

[0084] 200 parts of water;

[0085] 4 parts of dispersant;

[0086] 0-1 part of pH regulator;

[0087] 100 parts of titanium dioxide;

[0088] 10 parts of leveling agent;

[0089] Barium sulfate 15 parts

[0090] 5 parts mica powder

[0091] Heavy calcium 200 parts;

[0092] Acrylic emulsion 200 parts;

[0093] 5 parts of thickener;

[0094] 20 parts of film-forming aids;

[0095] 20 parts of pigment.

[0096] In the above three embodiments, the titanium dioxide is anatase titanium dioxide with a particle size of 900-1500 nm; the barium sulfate powder has a particle size of 500-800 nm.

[0097] The mass ratio of titanium dioxide to barium sulfate is 10:1-4...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com