Blast furnace injection coupling method for coking surplus gas based on microwave heating

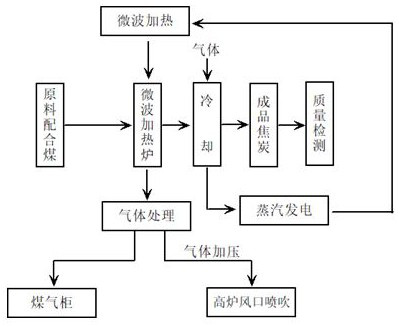

A microwave heating and gas technology, applied in the field of coking process, can solve the problems of polluting the environment, producing waste water or waste residue, etc., and achieve the effects of reducing the coke ratio of blast furnace, reducing CO2 emission, and increasing the output of coking.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0041] From the production plant, the particle size is less than 6mm, the ash content is A d Content is 7%, volatile matter V d The blended coal with a content of 29% is added to the crusher for crushing. After crushing, the proportion of blended coal with a particle size less than 3mm is 80%. Add 6% water to the crushed blended coal, and mix the blended coal with good moisture Put it into a microwave heating furnace container and heat it with microwaves. The heating system used in this example is: heating from room temperature to 1040°C for a heating time of 10 hours. In the process of coking, a large amount of gas is produced through tar capture and treatment. The tar capture adopts the existing technology of gas tar treatment equipment and its treatment process, which will not be repeated here. Part of the gas is pressurized to 360kPa by the compressor and sprayed directly through the nozzle. Into the blast furnace, the amount of gas injected is 150m 3 / tFe, compared with...

Embodiment 2

[0043] From the production plant, the particle size is less than 6mm, the ash content is A d Content is 9%, volatile matter V dThe blended coal with a content of 27% is added to the crusher for crushing. After crushing, the proportion of the blended coal with a particle size less than 3mm is 79%. Add 5% water to the crushed blended coal, and mix the blended coal with good moisture Put it into a microwave heating furnace container and heat it with microwaves. The heating system used in this example is: heating from room temperature to 1040°C for a heating time of 9 hours. In the process of coking, a large amount of gas is produced through tar capture and treatment. The tar capture adopts the existing technology of gas tar treatment equipment and its treatment process, which will not be repeated here. Part of the gas is pressurized to 350kPa by the compressor and sprayed directly through the nozzle. Into the blast furnace, the amount of gas injected is 130m 3 / tFe, compared wi...

Embodiment 3

[0045] From the production plant, the particle size is less than 6mm, the ash content is A d Content is 11%, volatile matter V d The blended coal with a content of 26% is added to the crusher for crushing. After crushing, the proportion of the blended coal with a particle size less than 3mm is 77%. Add 4% water to the crushed blended coal, and mix the blended coal with good moisture Put it into a microwave heating furnace container and heat it with microwaves. The heating system used in this example is: heating from room temperature to 1040°C, the heating time is 8h, and when the center temperature of the coke cake reaches 1040°C, keep the temperature for 1h. In the process of coking, a large amount of gas is produced through tar capture and treatment. The tar capture adopts the existing technology of gas tar treatment equipment and its treatment process, which will not be repeated here. Part of the gas is pressurized to 355kPa by the compressor and sprayed directly through th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com