A nickel-based solder ring and its preparation method

A nickel-based brazing filler metal, mass fraction technology, applied in welding equipment, manufacturing tools, metal processing equipment and other directions, can solve the problems of high brittleness, easy cracking and falling off, hard ring of nickel-based brazing filler metals, etc., and achieves high fineness. , Excellent elasticity, the effect of improving the bonding strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

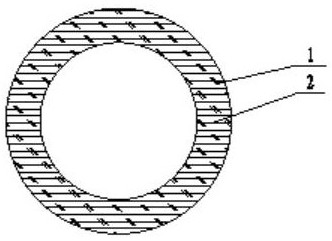

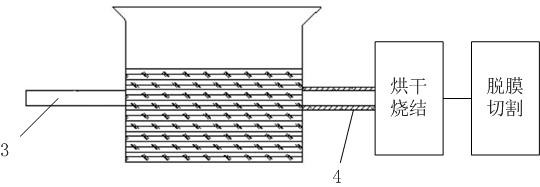

[0043] see figure 2 , further, the preparation method provided by the invention comprises the following steps:

[0044] S10: Obtain toughening fiber 1, nickel-based solder and lead-free glass powder 2 in parts by mass;

[0045] S20: Dissolving the toughening fiber 1 in acetone, ultrasonically dispersing for 10-15 minutes; adding epoxy resin, nickel-based solder and lead-free glass powder 2, and stirring evenly to obtain a slurry;

[0046] S30: Obtain the steel rod 3, coat the surface of the steel rod with dimethyl silicone oil, uniformly press-coat the slurry on the surface of the steel rod, dry, sinter, strip, and cut to obtain the nickel-based solder ring 4.

[0047] Wherein, the drying temperature is 100-120° C., and the drying time is 1-1.5 hours; the sintering temperature is 650-700° C., and the sintering time is 1.5-2 hours.

[0048] In the embodiment of the present invention, the dough-like slurry is press-coated on the surface of the steel bar, and then dried, sinte...

Embodiment 1

[0050] This embodiment provides a nickel-based solder ring, which includes the following components in parts by mass: 0.5 parts by mass of toughening fiber; 10 parts by mass of lead-free glass powder; and 89.5 parts by mass of nickel-based solder.

[0051] Wherein, the toughening fiber is carbon fiber, and the length of the toughening fiber is 2mm-3mm.

[0052] Lead-free glass powder is B 2 o 3 -SnO-ZnO, the particle size of the glass powder is 300-500 mesh.

[0053] The nickel-based solder is BNi-1, and the particle size of the nickel-based solder is 200 mesh to 300 mesh.

[0054] This embodiment also provides a method for preparing the above-mentioned nickel-based solder ring, comprising the following steps:

[0055] S10: Obtain toughening fiber, lead-free glass powder and nickel-based solder according to parts by mass;

[0056] S20: Dissolving the toughening fiber in acetone, and ultrasonically dispersing it for 10 minutes; adding epoxy resin, lead-free glass powder and...

Embodiment 2

[0060] This embodiment provides a nickel-based solder ring, which includes the following components in parts by mass: 2 parts by mass of toughening fiber; 16 parts by mass of lead-free glass powder; and 82 parts by mass of nickel-based solder.

[0061] Wherein, the toughening fiber is polyester fiber, and the length of the toughening fiber is 2mm-3mm.

[0062] Lead-free glass powder is B 2 o 3 -SnO-ZnO and B 2 o 3 -BaO-ZnO, the particle size of the glass powder is 300-500 mesh.

[0063] The nickel-based solder is BNi-1 and BNi-2, and the particle size of the nickel-based solder is 200 mesh to 300 mesh.

[0064] This embodiment also provides a method for preparing the above-mentioned nickel-based solder ring, comprising the following steps:

[0065] S10: Obtain toughening fiber, lead-free glass powder and nickel-based solder according to parts by mass;

[0066] S20: Dissolving the toughening fiber in acetone, ultrasonically dispersing for 12 minutes; adding epoxy resin, l...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com