Preparation method of Si3N4/BAS-based ceramic material

A technology of ceramic materials and silicon nitride powder, which is applied in the field of preparation of Si3N4/BAS-based ceramic materials, can solve the problems of difficult molding, non-uniform BAS phase, complex shapes and special-shaped products, etc., to achieve high solid content and solve density differences. , No effect of volatile organic compounds

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

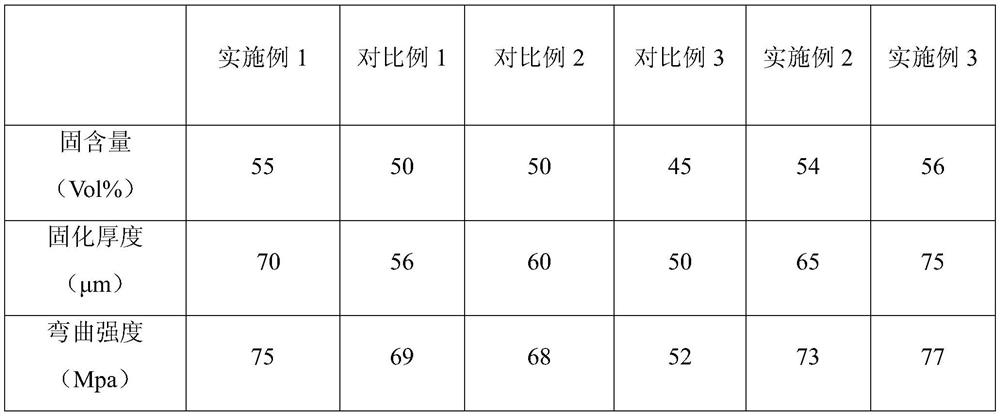

Examples

Embodiment 1

[0030] Step 1: Pretreatment of silicon nitride powder. First, ultrasonically disperse the silicon nitride powder in an aqueous solution of TEAOH to obtain a suspension (pH=9.8). Under magnetic stirring, add Al(NO 3 ) 3 and ammonia water (20-25wt%), after the reaction is completed (the pH of the solution remains unchanged during this process), the coating is washed three times with deionized water and alcohol respectively, dried at 80°C for 24h, and then dried at 600°C under a nitrogen atmosphere It can be calcined for 2 hours, wherein the coating is 18wt% of the mass of the silicon nitride powder;

[0031] Step 2: Powder mixing: uniformly mix the silicon nitride powder, barium carbonate and absolute ethanol pretreated in step 1, take out after ball milling for 5 hours, dry at 60°C for 36 hours, and pass through a 60-mesh sieve. The mass ratio of silicon carbide powder to barium carbonate is 5:1, and the mass ratio of powder to absolute ethanol is 1:3;

[0032] Step 3: slurry...

Embodiment 2

[0051] Step 1: Pretreatment of silicon nitride powder. First, ultrasonically disperse the silicon nitride powder in an aqueous solution of TEAOH to obtain a suspension (pH=9.8). Under magnetic stirring, add Al(NO 3 ) 3 and ammonia water (20-25wt%), after the reaction is completed (the pH of the solution remains unchanged during this process), the coating is washed three times with deionized water and alcohol respectively, dried at 80°C for 24h, and then dried at 600°C under a nitrogen atmosphere Calcining for 2 hours, wherein the coating is 20wt% of the mass of the silicon nitride powder;

[0052] Step 2: Powder mixing: uniformly mix the silicon nitride powder, barium carbonate and absolute ethanol pretreated in step 1, take out after ball milling for 5 hours, dry at 60°C for 36 hours, and pass through a 60-mesh sieve. The mass ratio of silicon carbide powder to barium carbonate is 5:1, and the mass ratio of powder to absolute ethanol is 1:3;

[0053] Step 3: slurry preparat...

Embodiment 3

[0057] Step 1: Pretreatment of silicon nitride powder. First, ultrasonically disperse the silicon nitride powder in an aqueous solution of TEAOH to obtain a suspension (pH=9.8). Under magnetic stirring, add Al(NO 3 ) 3 and ammonia water (20-25wt%), after the reaction is completed (the pH of the solution remains unchanged during this process), the coating is washed three times with deionized water and alcohol respectively, dried at 80°C for 24h, and then dried at 600°C under a nitrogen atmosphere It can be calcined for 2 hours, wherein the coating is 18wt% of the mass of the silicon nitride powder;

[0058] Step 2: Powder mixing: uniformly mix the silicon nitride powder, barium carbonate and absolute ethanol pretreated in step 1, take out after ball milling for 5 hours, dry at 60°C for 36 hours, and pass through a 60-mesh sieve. The mass ratio of silicon carbide powder to barium carbonate is 5:1, and the mass ratio of powder to absolute ethanol is 1:3;

[0059] Step 3: slurry...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com