Forming processing oiling agent suitable for treating heterocyclic aramid precursor

A molding process, heterocyclic aramid fiber technology, applied in fiber processing, fiber type, textile and papermaking, etc., to achieve excellent performance, stable product performance, and reduced fiber strength loss

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

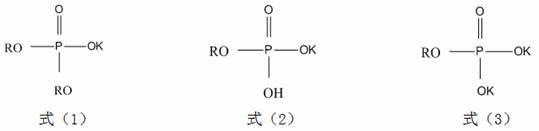

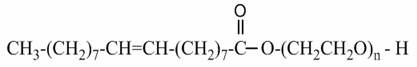

[0030] According to the mass percentage measurement, 1 kg of oil preparation is prepared. Each component is: isooctyl stearate [CAS number: 27214-90-0] 200g; n-butanol phosphate potassium salt (composed of the compounds shown in the following formula (1a) and formula (2a)) 400g; Polyethylene glycol monooleate [CAS number: 9004-96-0], molecular formula: C 18 h 33 o 2 .(C 2 h 4 O) 4 .H, 250g; polyoxyethylene sorbitan monooleate [CAS number: 9005-65-6] 150g.

[0031] Add the above components into a mixer, stir and mix evenly, and filter to remove the insoluble matter of the oil agent, so as to obtain the forming processing oil agent suitable for processing heterocyclic aramid fiber precursors of the present invention.

[0032] When in use, add the above-mentioned oil agent to the disperser, then add deionized water, and mix and shear at high speed to prepare an emulsion with a mass concentration of 1%, and then carry out oiling treatment on the heterocyclic aramid raw sil...

Embodiment 2

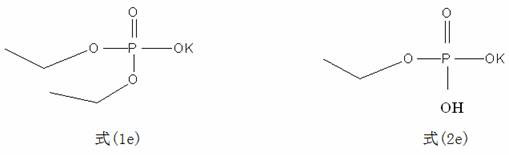

[0034] According to the mass percentage measurement, 1 kg of oil preparation is prepared. Each component is: isooctyl stearate [CAS number: 27214-90-0] 500g; n-octanyl phosphate potassium salt (represented by the following formula (1b), formula (2b), formula (3b) Compound composition) 200g; polyethylene glycol monooleate [CAS number: 9004-96-0], molecular formula: C 18 h 33 o 2 .(C 2 h 4 O) 5 .H, 200g; polyoxyethylene sorbitan monooleate [CAS number: 9005-65-6] 100g.

[0035]

[0036] Add the above components into a mixer, stir and mix evenly, and filter to remove the insoluble matter of the oil agent, so as to obtain the forming processing oil agent suitable for processing heterocyclic aramid fiber precursors of the present invention.

[0037] When in use, add the above-mentioned oil agent to the disperser, then add deionized water, and mix and shear at a high speed to prepare an emulsion with a mass concentration of 0.5%, and then carry out oiling treatment on the h...

Embodiment 3

[0039] According to the mass percentage measurement, 1 kg of oil preparation is prepared. Each component is: isooctyl stearate [CAS number: 27214-90-0] 500g; isoamyl alcohol phosphate potassium salt (composed of the compounds shown in the following formula (2c) and formula (3c)) 200g; Polyethylene glycol monooleate [CAS number: 9004-96-0], molecular formula: C 18 h 33 o 2 .(C 2 h 4 O) 6 .H, 250g; polyoxyethylene sorbitan monooleate [CAS number: 9005-65-6] 50g.

[0040]

[0041] Add the above components into a mixer, stir and mix evenly, and filter to remove the insoluble matter of the oil agent, so as to obtain the forming processing oil agent suitable for processing heterocyclic aramid fiber precursors of the present invention.

[0042]When in use, add the above-mentioned oil agent into the disperser, then add deionized water, mix and shear at a high speed to prepare an emulsion with a mass concentration of 0.1%, and then carry out oiling treatment on the heterocycli...

PUM

| Property | Measurement | Unit |

|---|---|---|

| shear strength | aaaaa | aaaaa |

| shear strength | aaaaa | aaaaa |

| degree of polymerization | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com